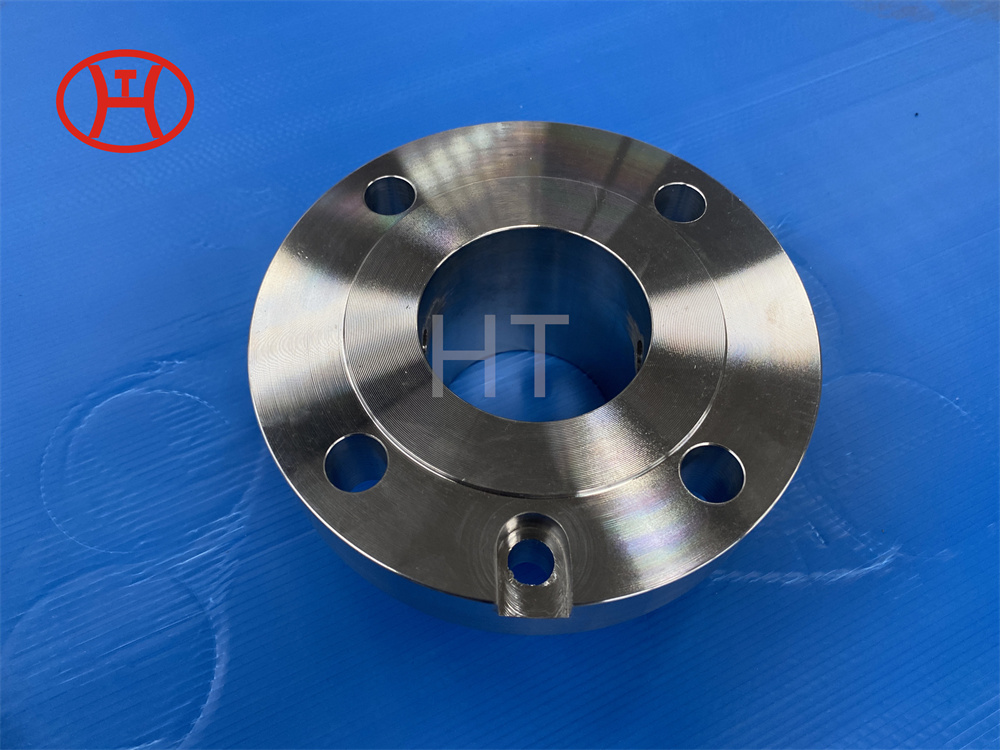

ANSI B16.5 SMO 254 WN Flange Supplier SMO 254 Socketweld Flange

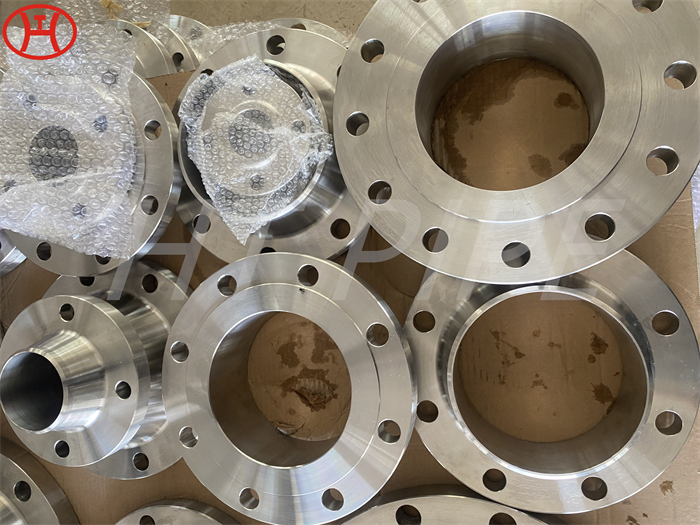

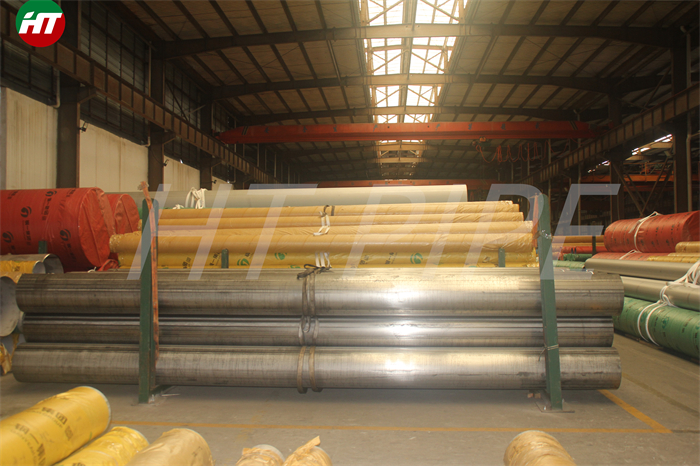

We manufacture these SMO 254 Flanges as per the national and international quality standards.

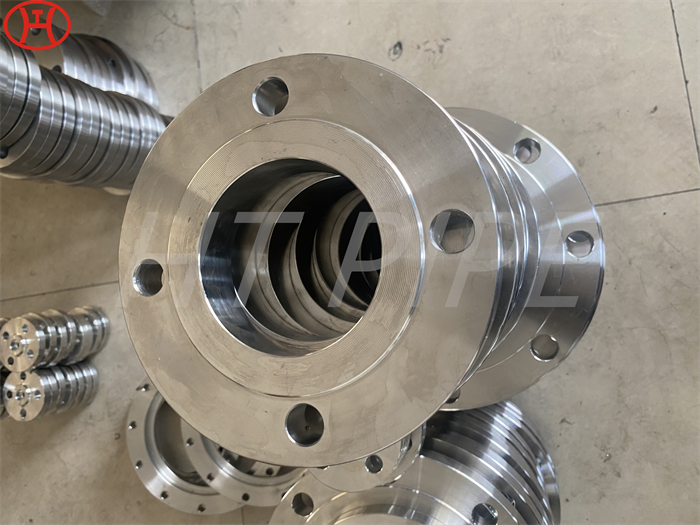

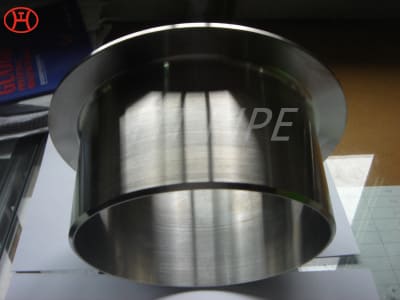

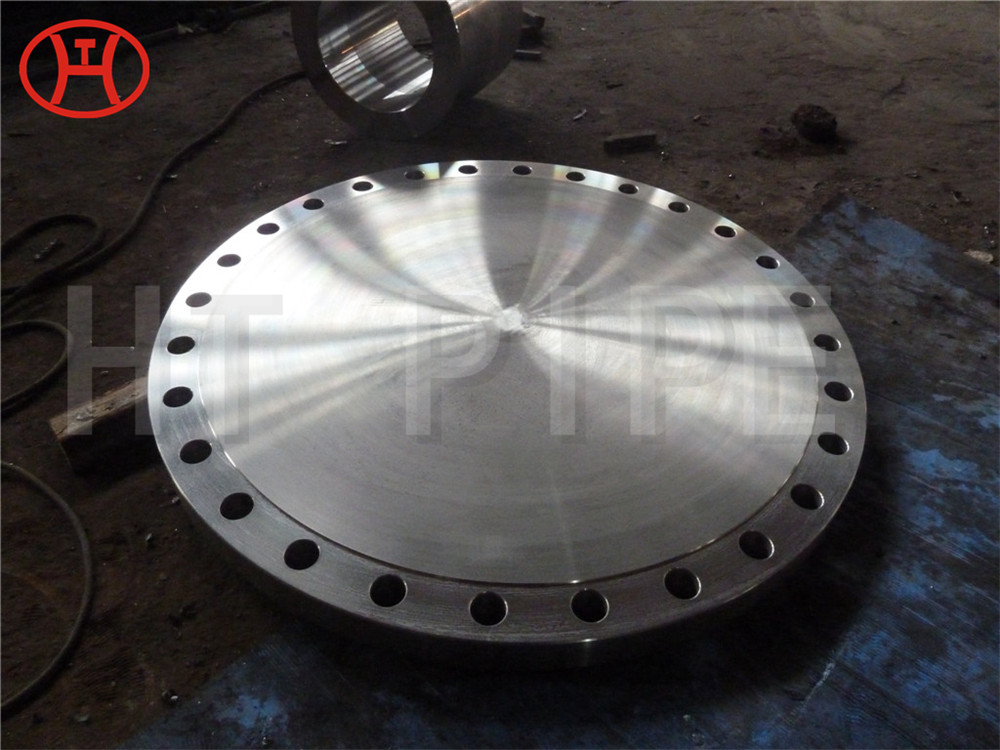

ASTM A182 SMO 254 Threaded Flanges, SMO Werkstoff No 1.4547 Socket Weld Flanges, SMO 254 Nippolet Flanges, SMO 254 RTJ Flange, 254 SMO WNRF Flanges Exporter, SMO 254 Blind Flanges, SMO 254 Weld Neck Flange Dealer in China.

SMO 254 Blind Flanges has been found to be a more cost effective substitute for high nickel and titanium alloys. SMO 254 Weld Neck Flanges is compatible with the common austenitic stainless steels. SMO 254 Lap Joint Flanges is developed for use in halide ¨C containing environment such as seawater, hydrochloric acid and contaminated sulphuric acid. SS A182 F44 Flanges make it able to perform well in chemical containing environments. These ASTM A182 SMO 254 Threaded Flanges have a superior quality of resistance. Additional Molybdenum offers excellent resistance to crevice and pitting corrosion cracking. We are offering SMO Werkstoff No 1.4547 Socket Weld Flanges, which has exceptional strength compared to other versions of stainless steel. We are using the most excellent quality of Austenitic Stainless-Steel for manufacturing these Flanges. This enhances features like durability, toughness, high tensile strength, and superior performance. SMO 254 Nippolet Flange has good fabricability, machinability, formability, and weldability. HT PIPE is producing SMO 254 RTJ Flanges in bulk amount without compromising in quality. By using the latest technology, modern machinery, and defined processes to fabricate Flanges, we can deliver perfectly suitable products to our esteem clients. As a customer-focused manufacturing firm, we are always offering excellence with all products.

ASTM A182 is the Standard Specification for Forged Stainless Steel Pipe Flanges and Stainless Steel Forged Fittings. ASTM 182 is use in pressure systems, Included are flanges, fittings and similar parts to specified dimensions or to dimensional standards, such as the ASME specifications. SMO 254 Flange is Material to F44 Super Austenitic Stainless Steel is described as a 6% Mo Flanges super austenitic stainless steel. The steel combines moderate mechanical strength (typically over 300 MPa yield strength) and high ductility with excellent corrosion resistance in seawater and a variety of industrial environments. Typically the alloy has a PREn(Pitting Resistance Equivalent) of 42-44 which ensures that the resistance to pitting corrosion is high. In addition, the steel provides good resistance to crevice corrosion. These Werkstoff No 1.4547 Flanges attributes mean that this high molybdenum stainless steel can be used successfully as an alternative to 300 series austenitic stainless steels (such as type 316) in applications where higher mechanical strength and/or enhanced resistance to pitting and crevice corrosion is required. This alloy possesses a lower yield strength than that of duplex stainless steel (and much lower than that of super duplex steel) and pitting resistance which is comparable to super duplex stainless steel (such as UNS S32760 / S32750). SMO 254 Flanges is readily available for applications in the industrial, architectural, and transportation fields.

Specification of SMO 254 Flange

| Range | : | 1/2”~60” |

| Specification | : | ASTM A812 / ASME SA812 |

| Dimensions | : | ANSI/ASME B16.5, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standards | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Class/Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500# | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |