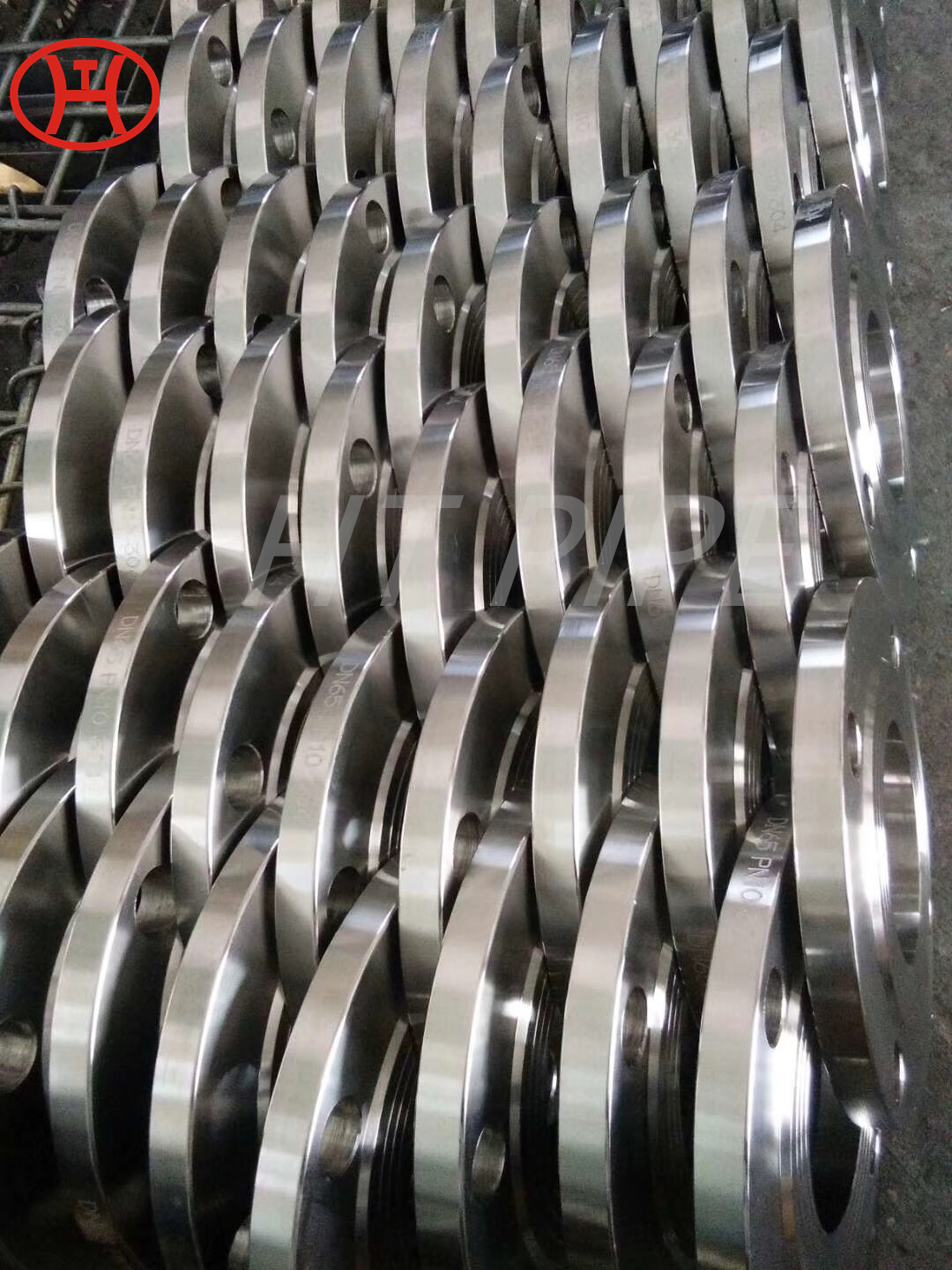

ANSI Carbon Steel-stainless steel flange manufacturer

Mild steel, it is a type of carbon steel. Carbon is present in all steels and when carbon is the main alloying element in steel it is called carbon steel. On the other hand, the amount of carbon present in the steel determines the type or grade of carbon steel. Mild steel has the lowest carbon content of any steel, but that doesn’t make it less useful. In fact, mild steel is the most commonly used steel grade, accounting for 85% of total U.S. steel production.

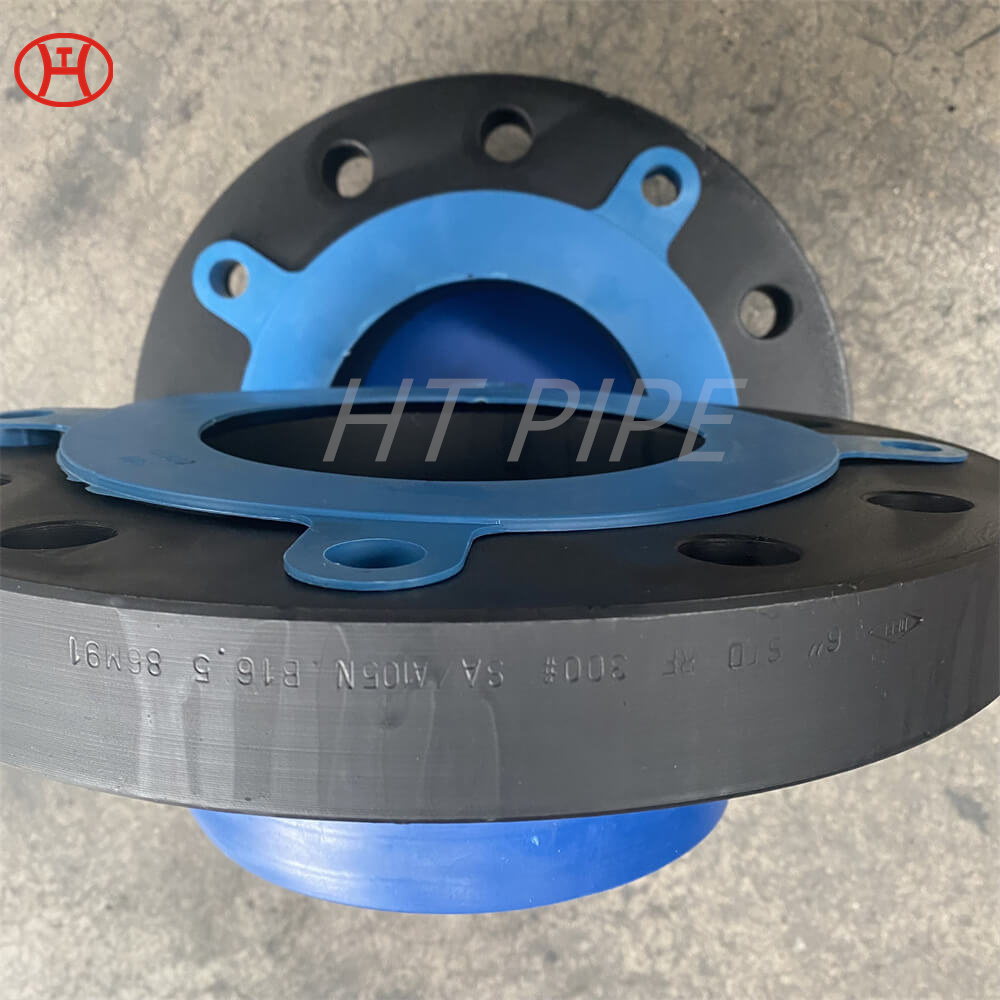

Specification Of Carbon Steel SA105 Pipe Flanges, Refer CS SORF Flanges A105 Pressure Rating.

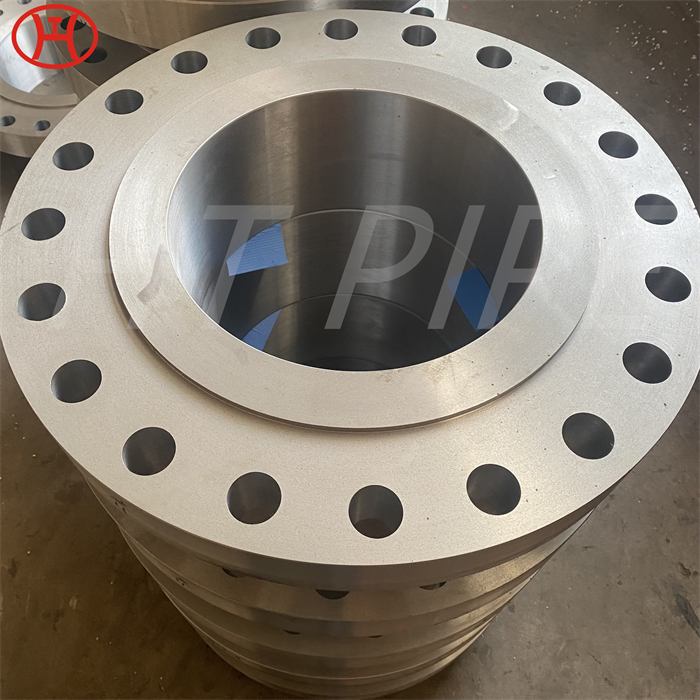

These SA 105 Forged Flanges have improved mechanical properties because forging refines and directs the flow of grain according to the shape of the piece, which in this case is the flange. ASME SA 105 Forging reduces the weight required to manufacture the ASTM A105n Weld Neck Flanges, therefore, thereby providing significant cost savings. Also, since the flanges have less excess, the CS SORF Flanges A105 would require less machining hours along with much less material which could be used to clean the piece at the end.

In order to improve its performance at elevated temperatures, the Carbon Steel ASTM A105 Blind Flanges are often heat treated by the performance of procedures such as annealing, normalizing, tempering, or quenching. After undergoing forging operations, the ASTM A105 Carbon Steel Flanges is to be subjected to tension test, hardness test and hydrostatic test, with the latter being applicable when required. Recommendations for retreatment, repair by welding, and product marking for the Carbon Steel SA105 Pipe Flanges are given in the specification. A105 Flange material is a forged carbon steel. ASTM A105 Flange Manufacturer in China produce different types and grades of the ASTM A105 Weld Neck Flange for sale. These are widely used in the market for non-critical applications. The ASTM A105 Blind Flange Material by default is not normalization heat treated. A105 Normalized Flanges are called the Ansi A105n Flanges where the n stands for normalization heat treatment. The heat treatment makes the Ansi A105 Flanges much harder and stronger.

Carbon Steel Pipe Flange Specifications

| Specifications | ASTM A105 Flange |

| Melting Point (Deg F) | 360 |

| Specific Gravity | 7.9 |

| Chemical Composition | Silicon [Si] (0.10-0.35), Carbon [C] (≤0.35), Sulfur [S] (≤0.40), Manganese [Mn] (0.60-1.05), Phosphorus [P] (≤0.35) etc. |

| Supporting Material | Gasket/ Ring Joint/ Flange Bolts |

| Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc | |

| Production Technique | Forged/ Heat treated and machined |

| Size | NPS 1⁄₂” Inch To NPS 48” Inch |

| JIS Standard | 5K/ 10K/ 16K 20K/ 30K/ 40K/ 63K |

| Other Standard | B16.47 Series A & B/ B16.48, BS4504/ GOST |

| UNI Standard | 6 Bar/ 10 Bar/ 16 Bar/ 25 Bar/ 40 Bar |

| Manufacturer Face Type | RTJ/ RF/ FF |

| Schedule Chart | SCH 5S To SCH 180. |

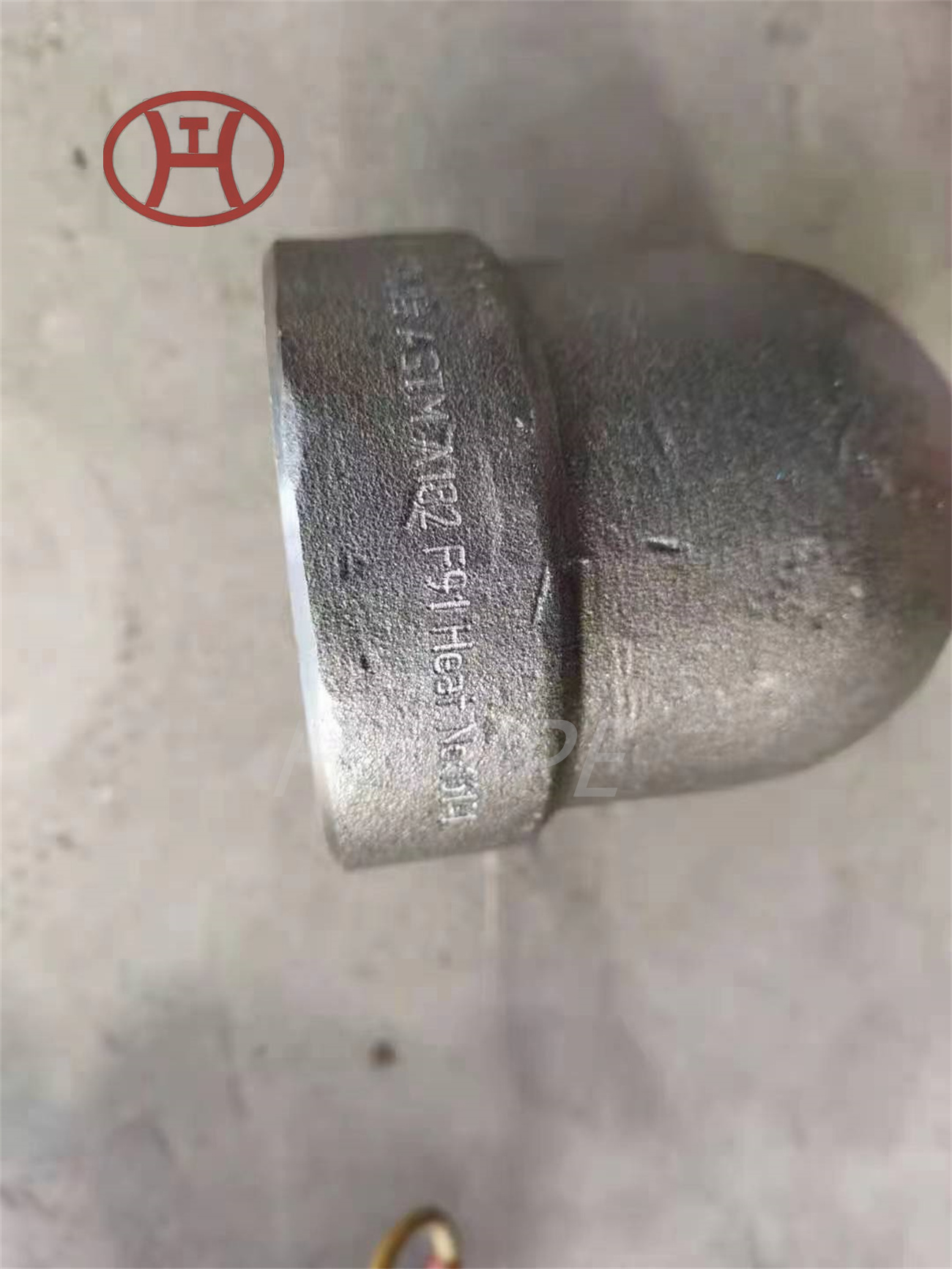

| Vishal Steel Manufacturer Below Types | Threaded/ Reducing/ Lap Joint/ Weld Neck/ Socket Weld/ Blind/ Slip On |

| Forging Methods | Forging & Casting, Rolling & Cutting |

| Class 300 Astm A105 Flange Application | Bitumen upgraders |

| Heavy oil refineries. | |

| Nuclear power (mostly seamless). | |

| Petrochemicals and acids. | |

| Astm A105 Flange Manufacturer In India | Forged/ Threaded/ Screwed / Plate |

| Manufacturer Pressure Class | Class 150 (lb) up to 24″ |

| Class 300 (lb) up to 20″ | |

| Class 600 (lb) up to 20″ | |

| Class 900 (lb) up to 16″ | |

| Class 1500 (lb) up to 10″ | |

| Class 2500 (lb) up to 8″ | |

| EN Standard | 6Bar/ 10Bar/ 16Bar/ 25Bar/ 40Bar |

| DIN Standard | PN6/ PN10/ PN16/ PN25/ PN40/ PN64 |

| Flange Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Coating | Anti-rust Paint/ Zinc Plated/ Oil Black Paint/ Yellow Transparent/ Cold and Hot Dip Galvanized |

| Flange Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |