ansi plasitc fittings for protect pipe flanges Inconel 718

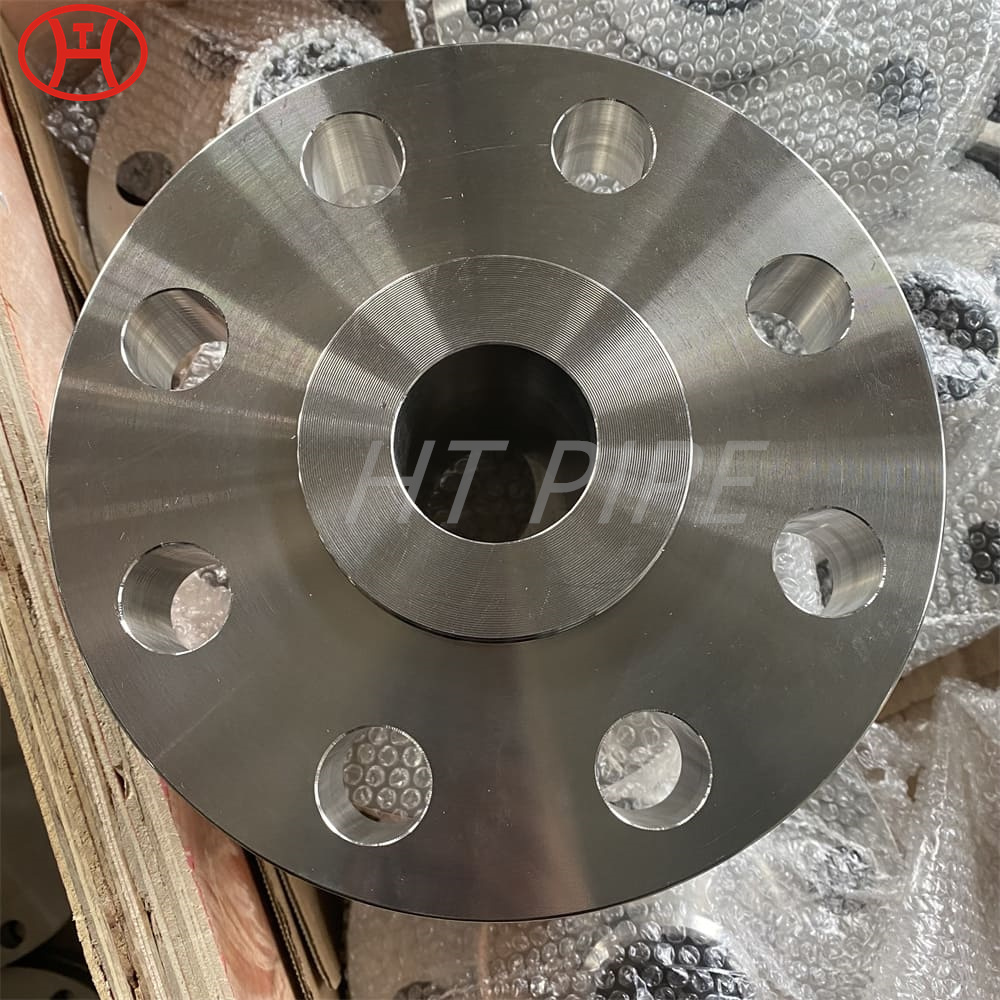

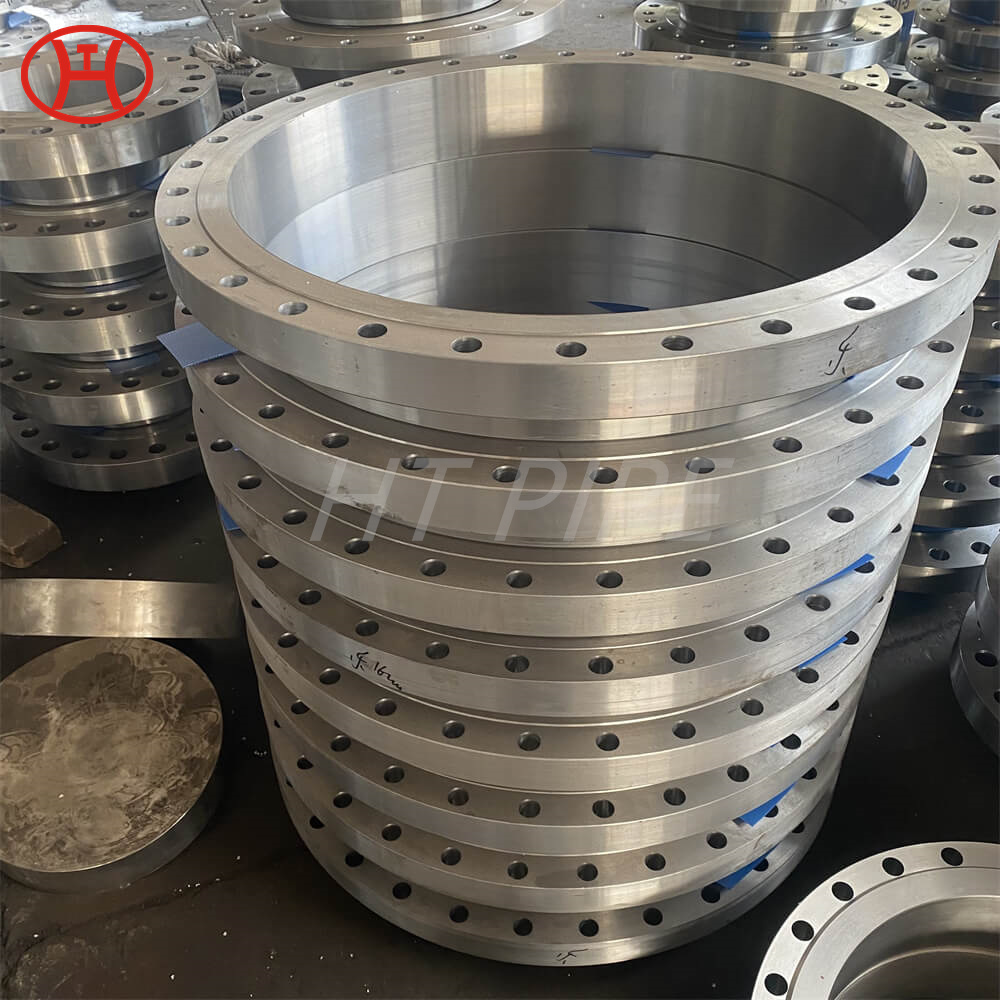

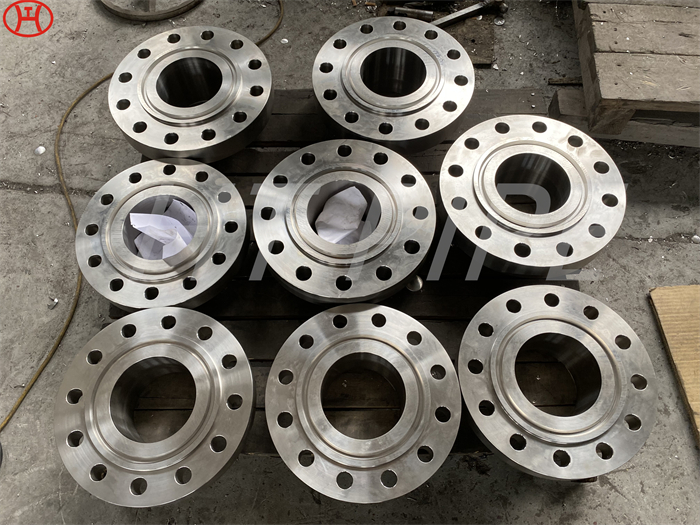

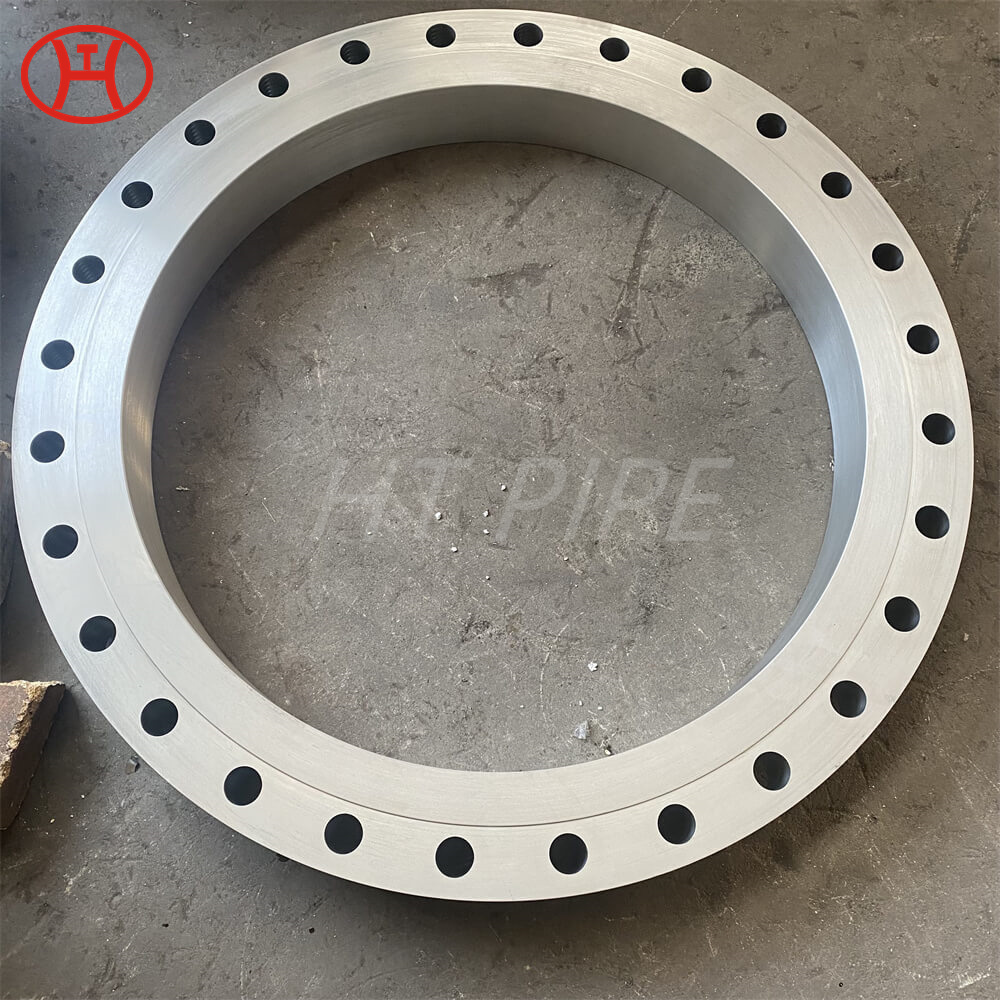

Our Inconel 718 flanges should be machined as rigid and overloaded as possible. These Inconel 718 flanges are used in aerospace applications such as aircraft and rocket engines for many critical components such as blades and sheets.

Our Inconel 718 blind flanges are used in gas turbines and rocket engines. However, high-strength versions of these Inconel 718 flanges are increasingly found in oilfield applications due to increasingly demanding environments. At the same time, the 718 blind flange has many excellent characteristics such as high tensile strength, firm structure, corrosion resistance, flexibility and durability. It also has other properties such as resistance to general corrosion, crevice corrosion, stress corrosion, pitting and oxidation.

In addition, Inconel 718 is designed with Nickel Chromium Molybdenum to resist a wide range of severe corrosive environments, crevice corrosion and pitting corrosion. This nickel steel allows exceptional performance at very high yield strengths, creep rupture properties at very high temperatures, and tensile strengths. Inconel 718 Nickel alloy is primarily used for long lasting service from cryogenic temperatures to 1200°F.