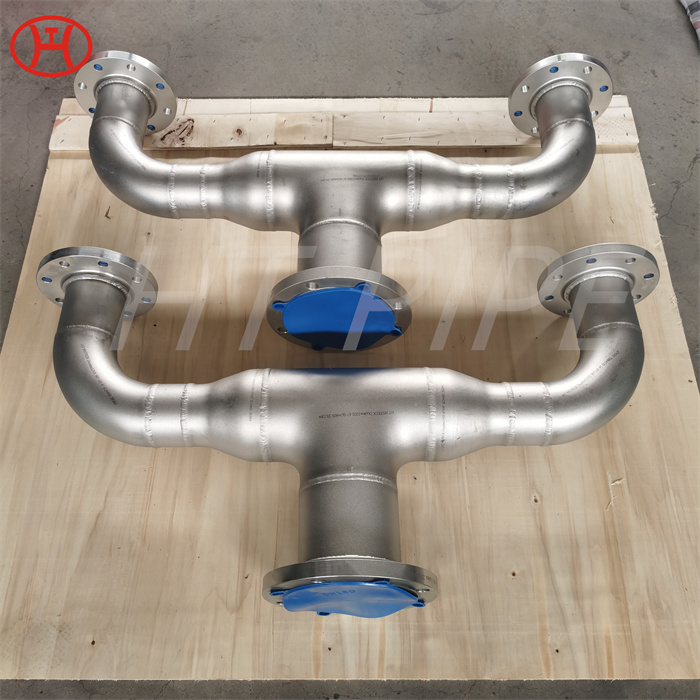

api bop parts precision casting parts nickel alloy BL flange Inconel 718 flange N07718 flange

Inconel 718 flanges are constructed of nichrome. The material has the characteristics of high density, high temperature resistance, high acid resistance, high strength and high price. There are different types of flanges with different sizes, dimensions and specifications.

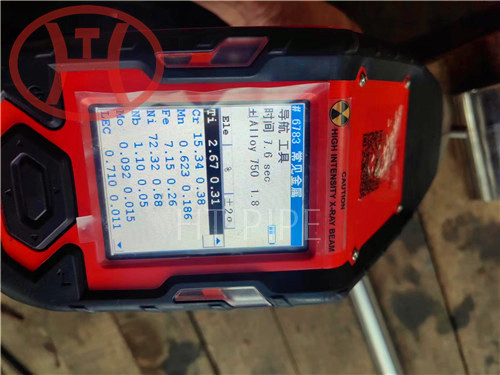

INCONEL contains a range of nickel-chromium alloys, including INCONEL 718. These alloys provide high strength, weldability and corrosion resistance in extreme temperature ranges. Meanwhile, UNS N07718 pipe flanges have a composition of 50% nickel 17% chromium and carbon, manganese, silicon, sulfur and copper. This gives the flange a minimum tensile strength of 930 MPa and a minimum yield strength of 482 MPa and an elongation of 45%.

The material also has a melting point of 1350 degrees Celsius, allowing the flange to withstand high temperatures. In addition, Inconel 718 is designed with Nickel Chromium Molybdenum to resist a wide range of severe corrosive environments, crevice corrosion and pitting corrosion. This nickel steel allows exceptional performance at very high yield strength, creep rupture properties at very high temperatures and tensile strength. Inconel 718 Nickel alloy is primarily used for long lasting service from cryogenic temperatures to 1200°F.