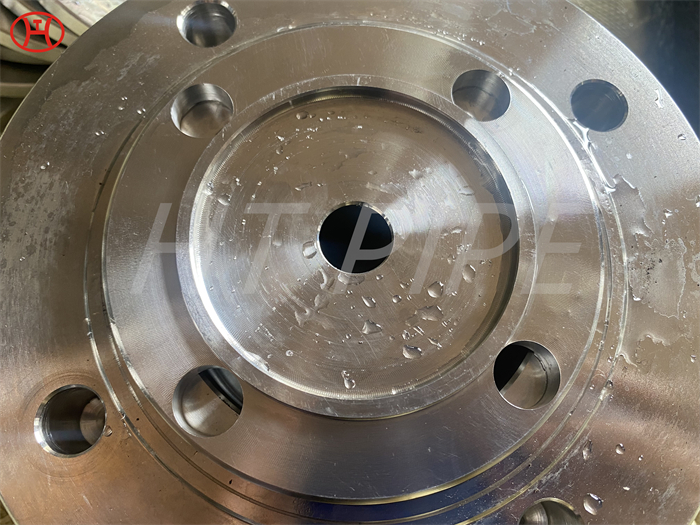

ASME ANSI B16.5 A105N Carbon steel flange demisions

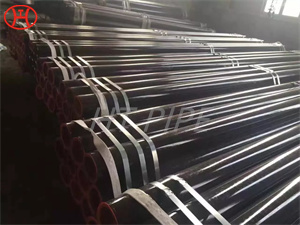

Carbon steel is a steel in which the main alloying element is carbon. Steel is considered carbon steel when there are no minimum requirements for chromium, cobalt, molybdenum, nickel, titanium, tungsten or other alloying elements. Carbon steel can be made harder and stronger through heat treatment. These hardness and strength measurements are determined by the carbon content – the higher the carbon content, the harder and stronger the steel will be.

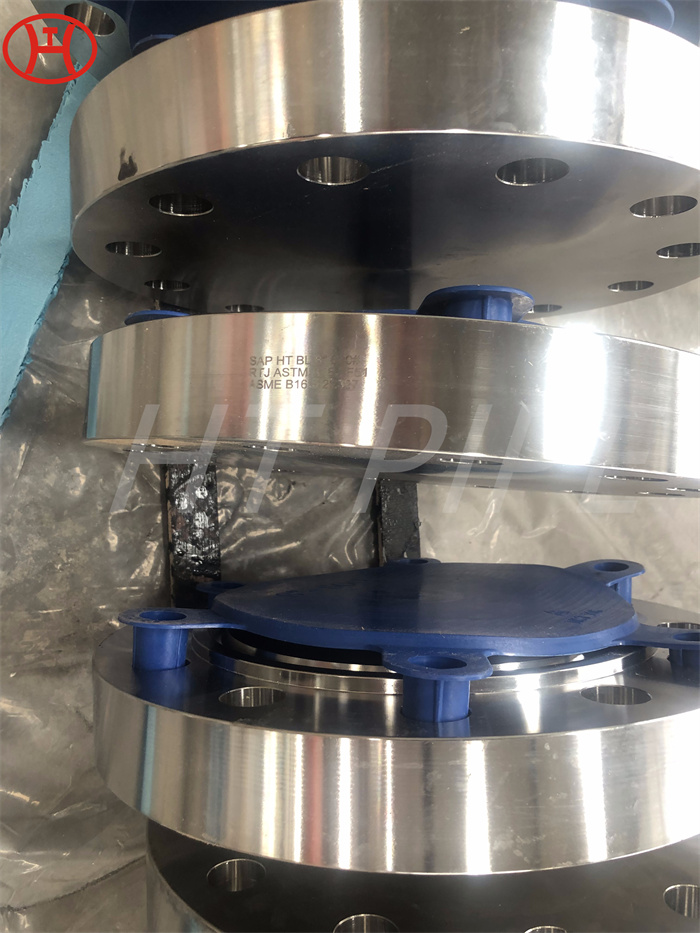

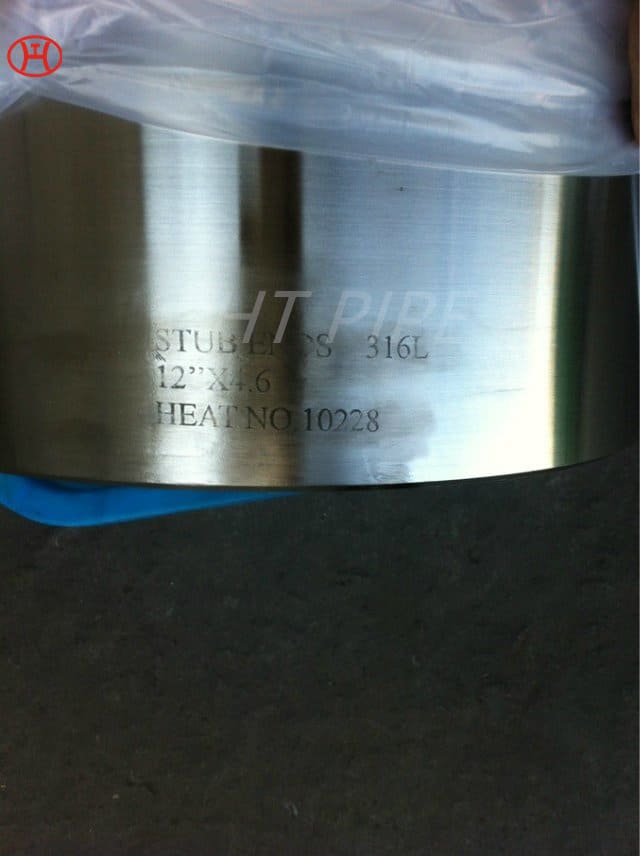

Manufacturer & Supplier Of Class 300 Asme Sa105N Blind And Slip On Flange As Per ASME/ ANSI B16.5

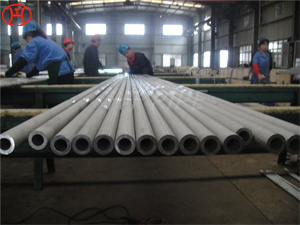

ASTM A105 Flange is a specification of flanges. The specification can include different grades of stainless steel material made flanges. The flanges are of forged carbon steel and are meant for high temperature services. HT PIPE is a leading manufacturer and supplier of the ASTM A105 Flange types.

The material has carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum and vanadium in its composition. Since the other materials are less than 1% of the composition, these are called the carbon steels. There are different types such as the SA105N Blind Flange which is used to close a pipe line. The flanges also have good strength properties. The minimum yield strength of the A105 flange is 250MPa and the minimum tensile strength is 485MPa. The A105 flange is also hard with a Brinell hardness score of 187.

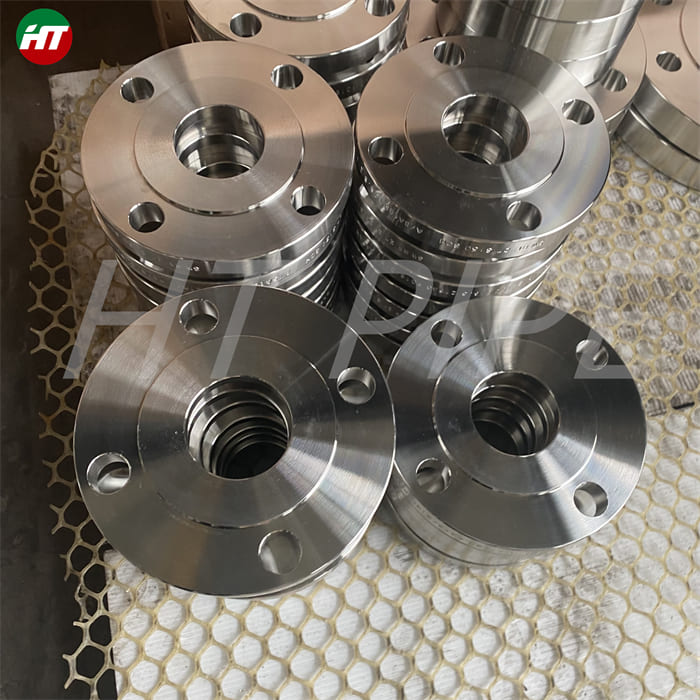

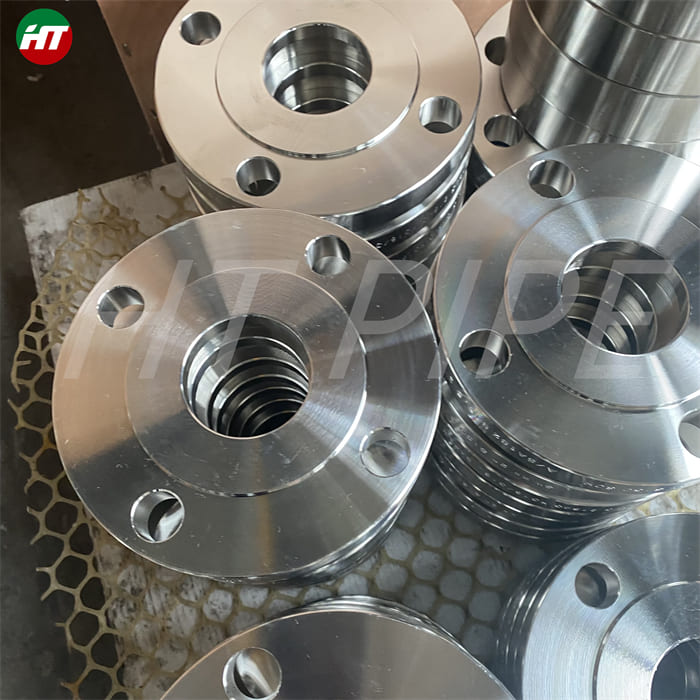

Carbon steel ASTM A105 Flange are made up of carbon steel or mild steel material. The material composition can have carbon, manganese, phosphorus, sulfur and iron in the composition. HT PIPE is a leading a105 carbon steel flanges manufacturers of these different carbon steel grades of flanges. Flanges are a type of connections for pipe lines to connect the pipes together. The specification for carbon steel material made flanges is the Asme Sa105N. There are different types of flanges based on the functionality such as the blind flange, slip on flange and orifice flange.

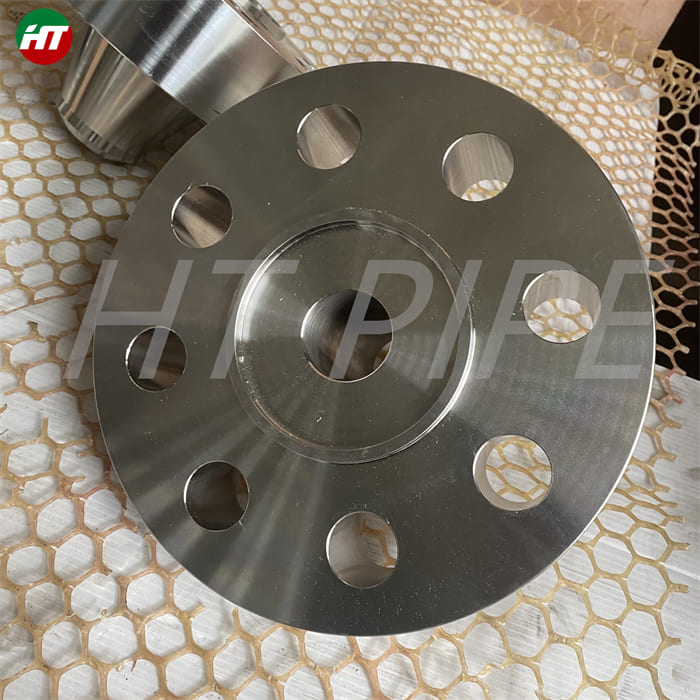

There are also different types based on the shapes. The carbon steel a105 blind flange is a very special type because it closes a connection and not expand it. The blind flanges can come in different varieties as well. The butterfly flange is an example. There are flat face, raised face and ring type joint flanges based on their face types. The cl.150 a105 lap joint flange ansi 16.5 is another type which has a lap joint on it for better connectivity. The flanges can range in size from ½ inches to 48 inches. The standards governing the dimensions can be ANSI, ASME, DIN, EN and other international standards.

The astm a105n weld neck flanges have a welded neck on them which allows better welding or fixture of the pipes into the flanges. The astm a105 slip on flange is used in most applications and it can come in different pressure classes ranging from 150 through 1500 and pressure numbers ranging from PN6 through PN64.

There are different pressure classes such as class 150, 300 and up to 2500 and PN6 through PN64. The A105 Class 300 Flange and below don’t need heat treatment while the higher pressure classes can undergo heat treatment. The A105 flanges over 4 inches nominal bore size are applied with annealing, normalizing, normalized and quenched or normalized and tempered types of heat treatments. The ASTM A105 Pipe Flanges can be forged as well. The A105 flange is good for welding applications. The boiler and pressure vessel guidelines as per ASME standards have to be followed while welding the material. There are also bolted as well as screwed flanges. When welding and bolting procedures are not appropriate, the ASTM A105 N Screwed Flange comes handy. The screwed flanges can be applied with threaded pipes to make a connection without the need for welding. Please contact us for the pricing and further information on the flanges.

Specification Format of SA105N Blind Flange

| Specifications | ASTM A182, ASME SA182 |

| Size | 1/2″ to 48″ |

| Standards | ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605. |

| Pressure Ratings | Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600 |

| Flange Face Type | Flate Face, Raised Face, Ring Type Joint |

| Coating/Surface Treatment | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated. |

Mechanical Analysis Of ASTM A105N Screwed Flanges

| MECHANICAL PROPERTIES | REQUIREMENTS |

|---|---|

| Tensile strength,min,psi [MPa] | 70000 [485] |

| Yield strength,min,psi [MPa] | 36000 [250] |

| Elongation, min, % | 30 |

| Reductionofarea,min,% | 30 |

| Hardness,HB,max | 187 |

Chemical Formula Of ASTM A105 Pipe Flanges

| ELEMENT | COMPOSITION, % |

|---|---|

| Carbon | 0.35 max |

| Manganese | 0.60-1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10-0.35 |

| Copper | 0.40 max (1) |

| Nickel | 0.40 max (1) |

| Chromium | 0.30 max (1-2) |

| Molybdenum | 0.12 max (1-2) |

| Vanadium | 0.08 max |