ASME B16.48 Hastelloy Alloy C2000 Flat Flanges Stockholders Alloy C2000 Lap Joint Flanges

It is able to withstand a wide range of oxidizing and non-oxidizing chemicals, and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides.

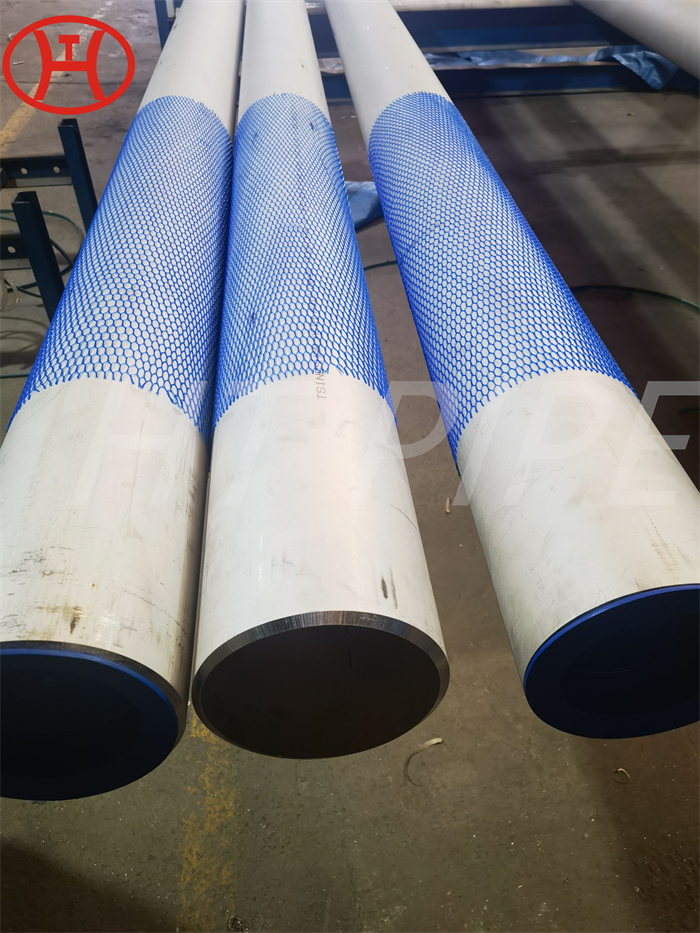

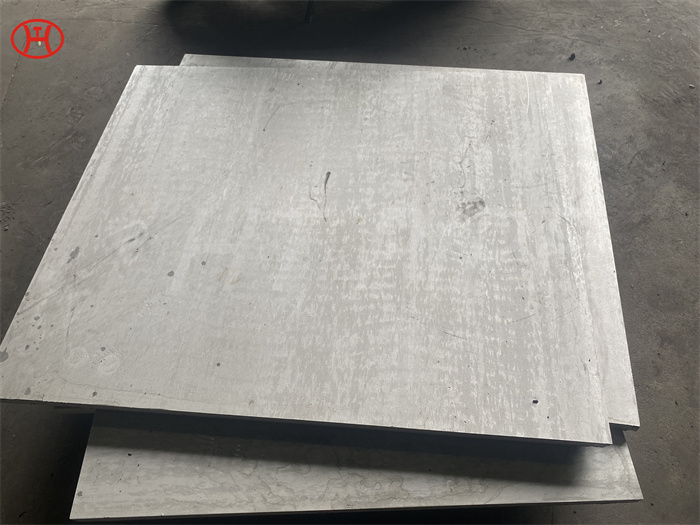

Hastelloy C2000 Blind Flanges work harden more quickly than the majority of austenitic stainless steels, and they might need to undergo several stages of cold work with anneals in between. The product is made using the modern machinery that ensures their durability and reliability. The product is designed to keep in mind the needs and demands of the customers. These flanges are mostly designed on the basis of changing market patterns. They are made from the great quality raw materials and three alloys such as molybdenum, nickel, and chromium. Alloy C2000 Flanges averts SCC and corrosion by dissimilar kinds of chemicals like sulphuric acid, hydrofluoric acids and hydrochloric acid. Alloy C2000 Pipe Flanges broadens the range of the nickel-chromium-molybdenum alloy family with the addition of copper which allows for resistance to an extensive range of corrosive chemicals. While cold work does not usually affect the resistance of HASTELLOY C-2000 Alloy Flanges to general corrosion, and to chloride-induced pitting and crevice attack, it can affect resistance to stress corrosion cracking.