ASME B16.5 ASTM A182 UNS S31254 Blind Weld Neck Slip On And Socket Weld Flange Manufacturer

The SMO 254 Spectacle Blind Flange Also- Resists Crushing In High Machine Fittings. Additionally, The 6mo Flanges Properties Includes Corrosion Resistance, Which Is Useful For Services In Corrosive Media Containing Environments.

Best Price of SMO 254 WNRF Flanges Exporter, SMO UNS S31254 Industrial Flanges, Stockholder Of SMO 254 RTJ Flange, ASME SA182M SMO 254 Class 300 Flange Wholesaler, SMO 254/6Mo Flat Flange, SMO 254 EN 1092-1 Flanges Traders in China.

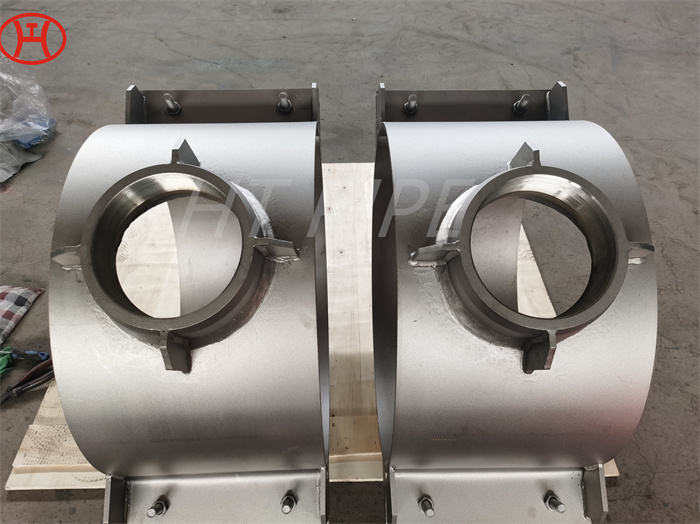

A182 F44 Flanges are components designed to possess unique pressure classes. A pressure class in a flange can be determined as the maximum allowable pressure a flange can withstand when there is a gradual surge of temperature across the system. 1.4547 flange pressure is characterized by different standards set by different unions. A Class 300 ASTM A182 UNS S31254 flange is not the least but also not the strongest flange. These 254 SMO Flanges are designed to have optimum pressure resistance up to 570psi in temperatures of 600 degrees F. As there is a gradual increase in the temperature, the pressure tolerance in the flange slowly recedes. We are a manufacturer, supplier and exporter of SMO 254 Flanges in a number of specifications, class, schedule, grade and size to meet the demands of your industry. ASTM A182 SMO 254 Blind Flanges that have a solid centre with bolt holes drilled on the rim, allowing quick bolt hole alignment. Aside from this, they are a cost-cutting and profit inducing devices if used in high chloride environments, like the pulp, paper, pulp mills, and other chloride producing operations, as the Molybdenum repels any chloride threats.

Our UNS S31254 SMO 254 Threaded Flanges can be counted as another useful product, as they exhibit remarkable stress corrosion cracking and corrosion fatigue, available in several pipe diameter and thicknesses, these highly ductile and strong flanges serve important purposes in the petroleum production and desalination plants. Alloy 254 SMO or the Astm A182 F44 Material is a very high end, molybdenum and nitrogen alloyed super austenitic stainless steel. This alloy has a very low content of carbon. The 6mo Plate Flange displays outstanding resistance to crevice corrosion stress cracking, pitting, as well as corrosion fatigue uniform corrosion. The SMO 254 Spectacle Blind Flange is considerably much stronger as compared to the standard or conventional austenitic grade alloys. The tensile strength of the Alloy 254 SMO is nearly two times that of grade 300 series stainless steel. The UNS S31254 Weld Neck Flange is also characterized by its high ductility as well as high impact strength. With high levels of chromium, molybdenum, and nitrogen content , the alloy is frequently used in high chloride containing environments. For example, the UNS S31254 Pipe Flange is used in environments such as seawater, brackish water, pulp mill bleach plants, and other chloride process streams.

ASTM A182 SMO 254 Plate Flanges Chemical Composition

| Grade | % | Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

| SMO 254 | Min. | 17.5 | 19.5 | 6 | 0.5 | 0.18 | |||||

| Max. | 18.5 | 20.5 | 6.5 | 1 | 0.22 | 0.02 | 1 | 0.8 | 0.03 | 0.01 |

Mechanical properties of ASTM A182 SMO 254 Pipe Flange

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SMO 254 | 8.0 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |