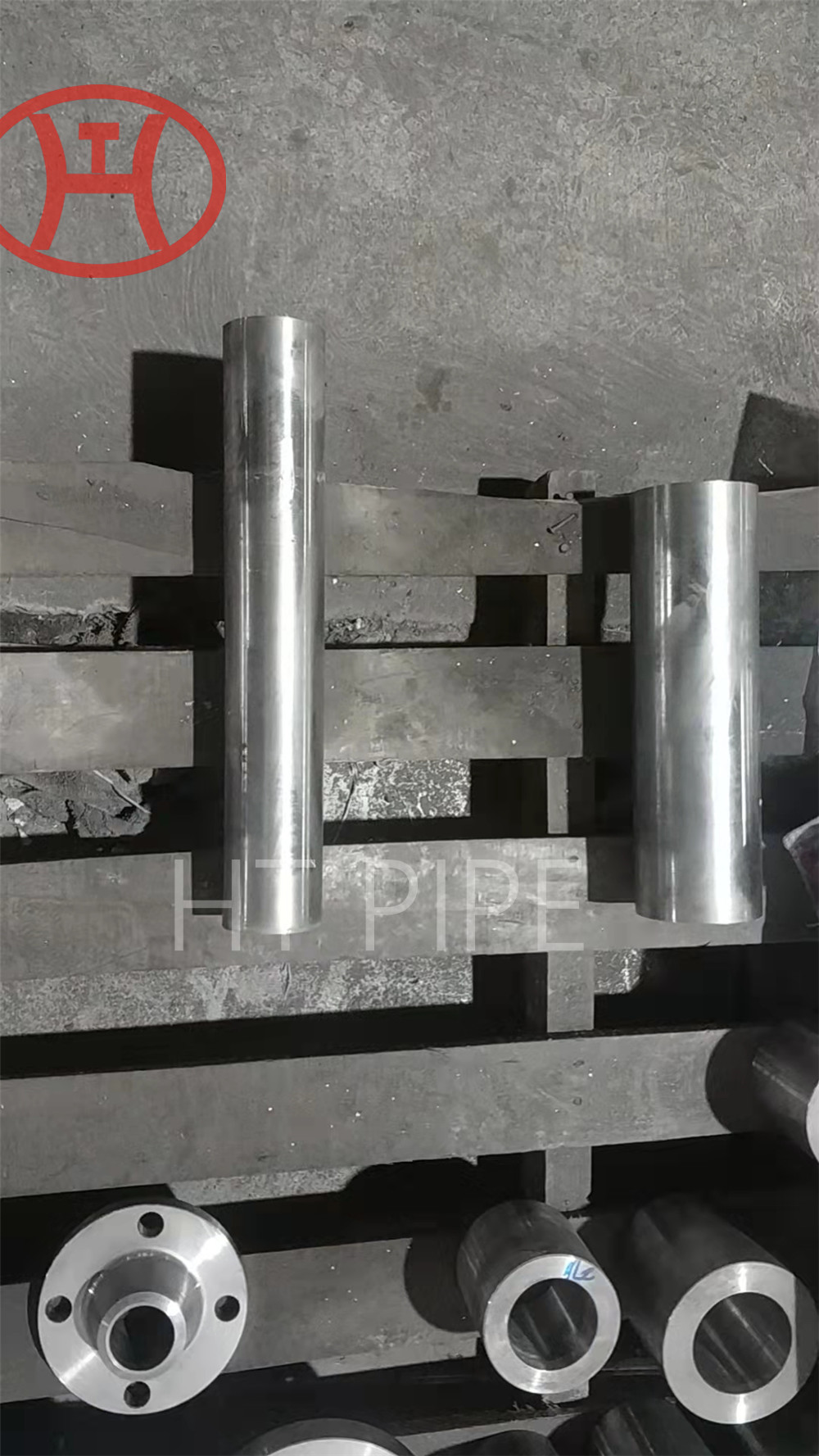

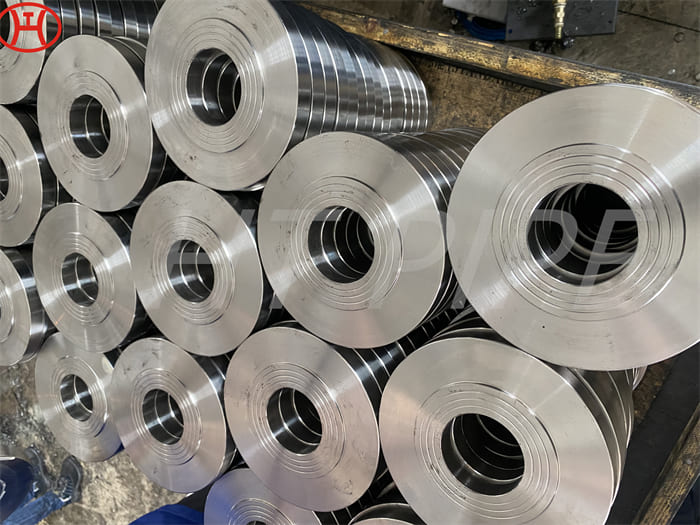

ASME B16.5 Hastelloy C276 Long Weld Neck Flange

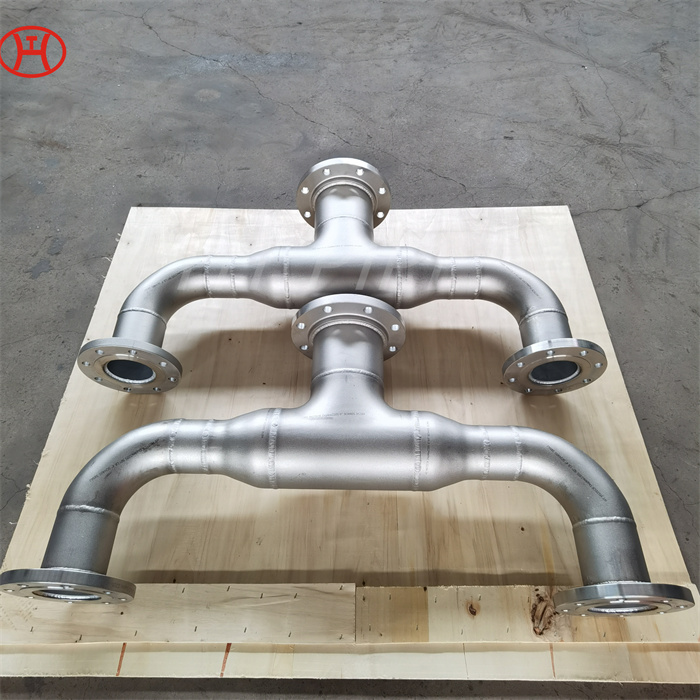

The flange is second most used joining method after welding. Flanges are used when joints need dismantling. It provides flexbility for maintenance. Flange connects the pipe with various equiment and valves. Breakup flanges are adde din the pipeline system if regular maintenance in required during plant operation.

A flanged joint is composed of three separate and independent although interrelated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls ae required in the selection and application of all these elements to attain a joint, which has acceotable leak tightness.

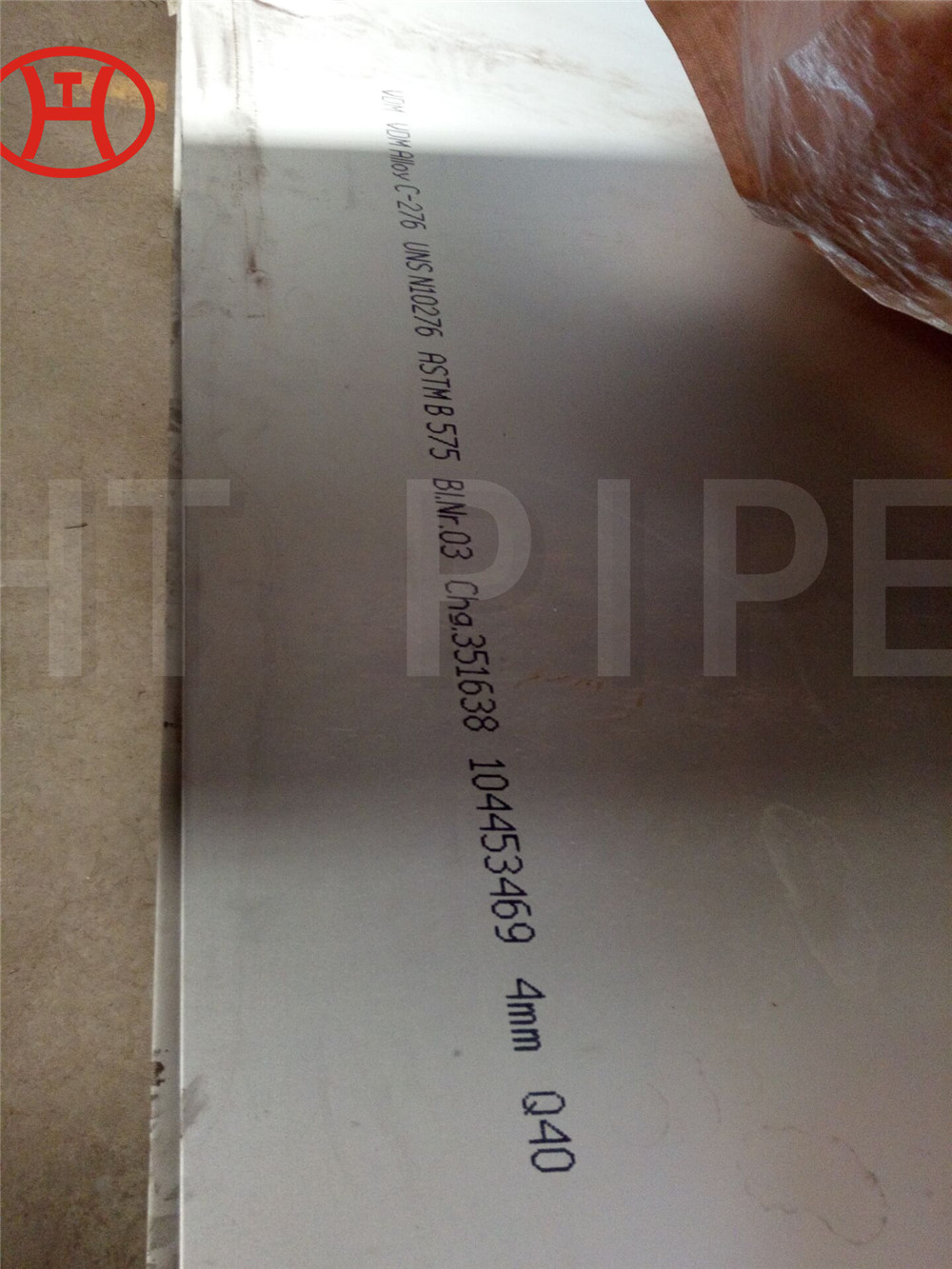

HASTELLOY C276 is a Nickel-chromium-molybdenum wrought alloy that is considered the most versatile corrosion resistant alloy available. This alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in an as welded condition. Alloy C-276 also has excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900¡ãF. Alloy C-276 has exceptional resistance to a wide variety of chemical environments.

This alloy is also one of the top performing materials for use in oilfield applications, especially

in the recovery and handling of ¡°sour¡± natural gas, which contains hydrogen sulfide and carbon dioxide

and chlorides. The high nickel, chromium and molybdenum content of Alloy C276 make it extremely

resistant to these environments.