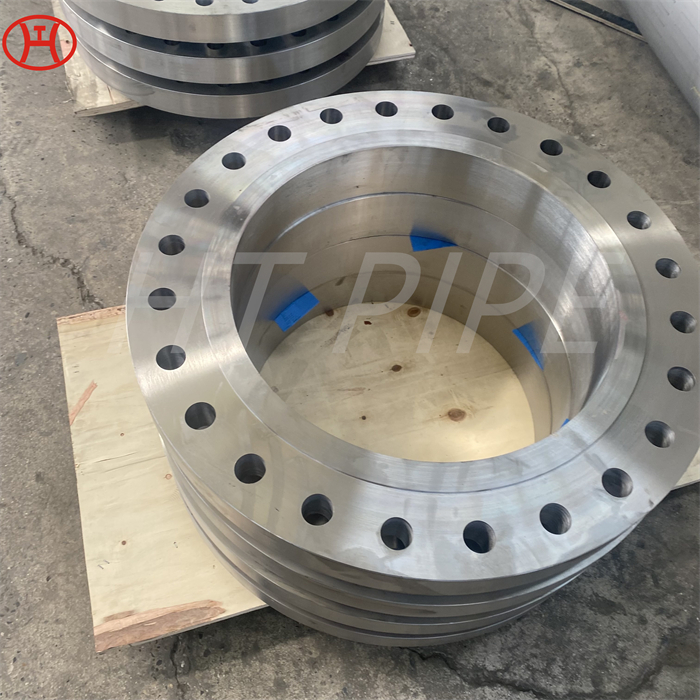

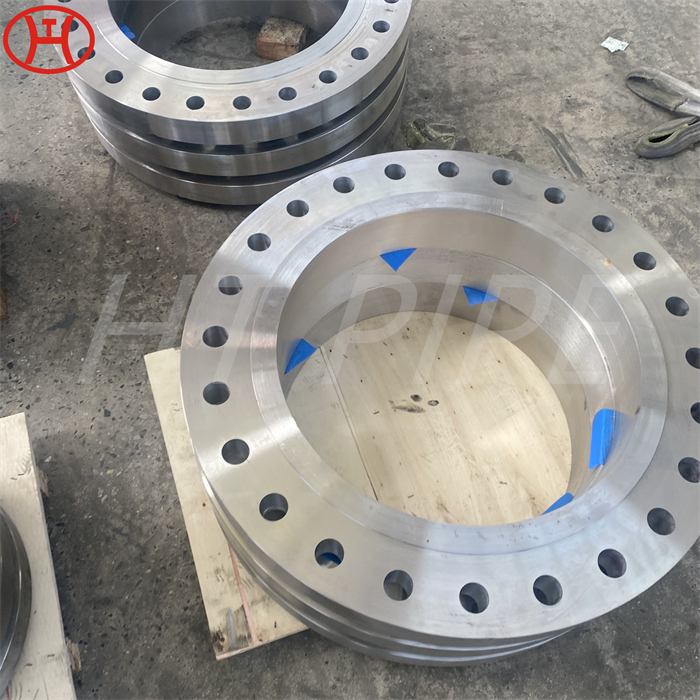

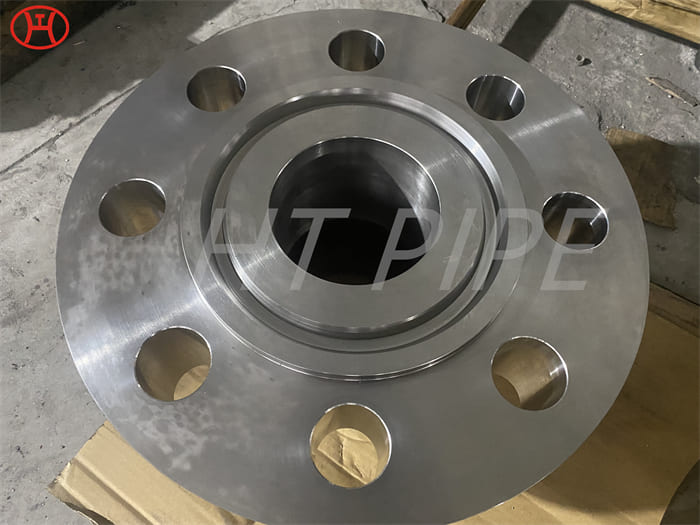

ASME B16.9 A234 WPB Butt Welded Carbon Steel Pipes and Fittings

When it comes to connecting different sections of carbon steel pipes, ASME B16.9 A234 WPB Carbon Steel Pipe Butt Welded Fittings are the go-to solution. These fittings are designed to provide a reliable and secure connection, while also ensuring excellent flow through the system.

ASME B16.9 A234 WPB Carbon Steel Pipe Butt Welded Fittings, A234 WPB Butt Welded Fittings Manufacturer, A234 WPB Carbon Steel Pipes and Fittings, A234 WPB Carbon Steel Pipe Elbow, A234 WPB Carbon Steel Pipe Tee, A234 WPB Carbon Steel Pipe Reducer, ASME B16.9 Carbon Steel Pipes and Fittings.

When it comes to connecting different sections of carbon steel pipes, ASME B16.9 A234 WPB Carbon Steel Pipe Butt Welded Fittings are the go-to solution. These fittings are designed to provide a reliable and secure connection, while also ensuring excellent flow through the system.

ASME B16.9 is a standard for carbon steel pipe fittings that covers the design, dimensions, tolerances, testing, and certification of these critical components. The standard specifies the requirements for A234 WPB Butt Welded Fittings such as elbows, tees, reducers, caps, and stub ends, in sizes ranging from ½ inch to 48 inches in diameter.

One of the key benefits of A234 WPB Carbon Steel Pipes and Fittings is their ability to withstand high levels of pressure and temperature. This makes them ideal for use in a wide range of industrial applications, including oil and gas, power plants, chemical processing, and more.

A234 WPB carbon steel is commonly used to manufacture ASME B16.9 butt welded fittings. This material has excellent strength and durability, making A234 WPB Carbon Steel Pipe Elbow a reliable choice for demanding applications. It is also relatively easy to work with, which allows for efficient manufacturing processes.

The manufacturing process for A234 WPB Carbon Steel Pipe Tee involves several steps, including cutting, forming, welding, and finishing. Each fitting is carefully crafted to meet the specific requirements of the application, ensuring a precise and secure fit.

In addition to their superior strength and durability, A234 WPB Carbon Steel Pipe Reducer are also highly versatile. They can be used with a range of pipe materials, including carbon steel, stainless steel, and alloy steel. This enables them to be used in a wide range of applications, from high-pressure gas systems to corrosive chemical processing.

ASME B16.9 Carbon Steel Pipes and Fittings are a reliable and effective choice for connecting different sections of pipes in industrial settings. With their rugged construction, precise manufacturing, and versatility, they are an essential component in a wide range of pipelines.

SA234 WPB Elbow Chemical Composition

Chemical Composition (%) of ASTM A234 Pipe Elbow & ASTM A234 Pipe Elbow

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | – | – | – | – |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | – | – | – | – |

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cr and Mo shall not exceed 0.32%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

ASTM A234 Sr Elbow Mechanical Properties

Check below ASTM A234 WPB Elbow Mechanical Properties before you order.

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |