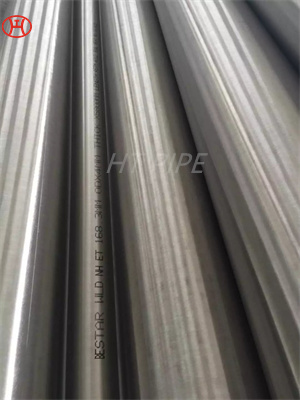

ASME B36.19M Stainless Steel Pipe

ASME B36.19M is the standard specification for stainless steel pipes, which specifies the dimensions, tolerance, and manufacturing requirements for both welded and seamless pipes.

ASME B36.19M Stainless Steel Pipe, ASME B36.19 SS Pipe, ASME B36.19 Steel Pipe.

ASME B36.19M is the standard specification for stainless steel pipes, which specifies the dimensions, tolerance, and manufacturing requirements for both welded and seamless pipes.

This guide will provide you with a comprehensive overview of ASME standard B36.19M stainless steel pipes, including its features, applications, and types.

Features of ASME B36.19M Stainless Steel Pipes

ASME B36.19M stainless steel pipes are known for their outstanding features, including:

Corrosion Resistance: Stainless steel is resistant to corrosion, making Welded and Seamless Pipes ideal for use in harsh environments.

High Strength: Stainless steel has high strength, enabling it to withstand high pressure and temperature conditions.

Ease of Fabrication: Stainless steel can be easily fabricated using welding, bending, and cutting techniques, making it easy to work with.

Low Maintenance: Stainless steel requires minimal maintenance, making it cost-effective in the long run.

Applications of ASME standard B36.19M Stainless Steel Pipes

ASME B36.19M stainless steel pipes are widely used in various industries, including:

Oil and Gas: Stainless steel Welded pipes are used in oil and gas industries to transport oil and gas from the wellhead to the processing plant.

Chemical Processing: Stainless steel Seamless pipes are used in chemical processing industries to transport corrosive chemicals and acids.

Pharmaceuticals: Stainless steel Welded pipes are used in pharmaceutical industries to transport liquids and gases.

Food and Beverage: Stainless steel Seamless pipes are widely used in food and beverage industries due to their corrosion resistance properties.

Types of ASME B36.19M Stainless Steel Pipes

ASME B36.19M stainless steel pipes are available in various types, including:

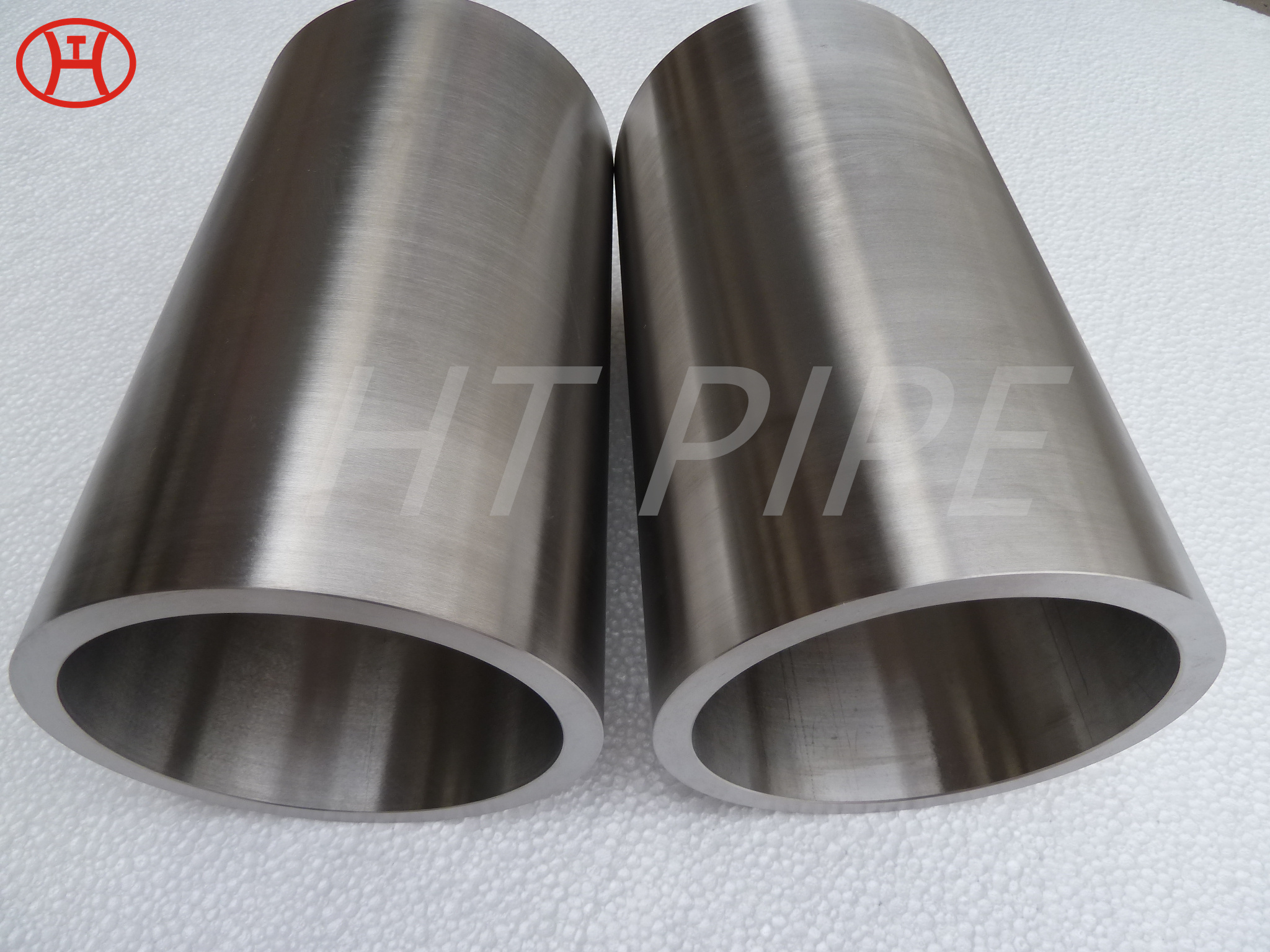

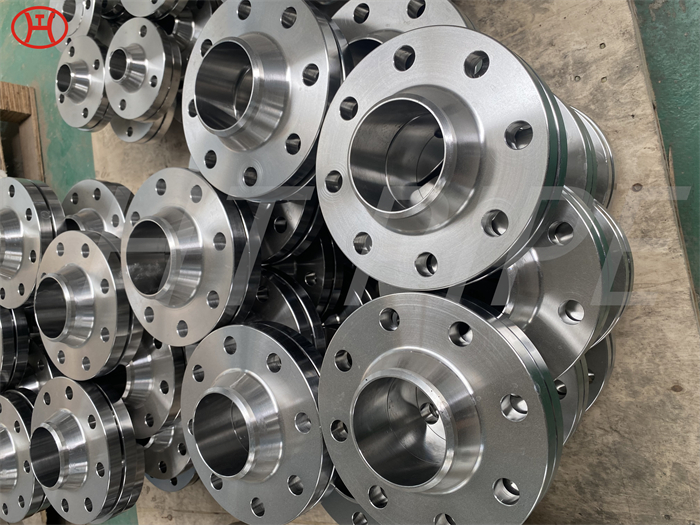

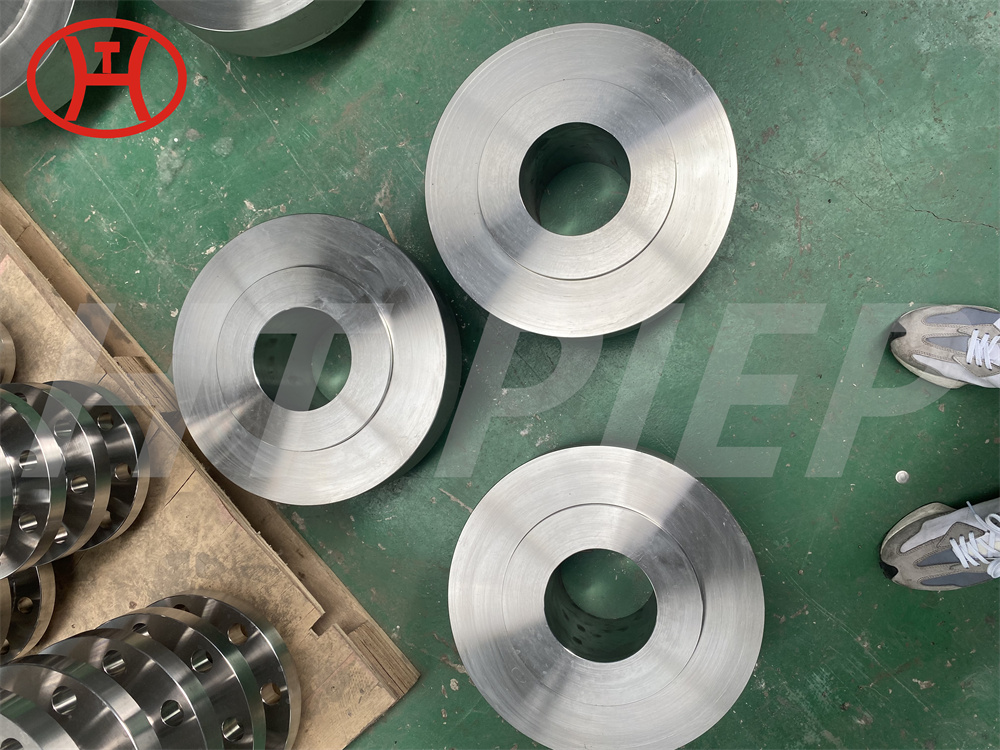

Welded Pipes: Welded pipes are formed by welding two or more pieces of stainless steel together and are commonly used in industrial applications.

Seamless Pipes: Seamless pipes are made from a single piece of stainless steel and are commonly used in applications requiring high pressure and temperature resistance.

Round Pipes: Round pipes are the most common type of stainless steel pipes, used in a variety of industrial and commercial applications.

Square Pipes: Square pipes are used in architectural and construction applications due to their visually appealing design.

Rectangular Pipes: Rectangular pipes are commonly used in construction, transportation, and electrical applications.

ASME B36.19M stainless steel pipes are widely used in various industries due to their outstanding features, including corrosion resistance, high strength, ease of fabrication, and low maintenance. It is important to understand the various types and applications of stainless steel pipes to choose the right type for your specific needs.

*Dimensions and weights for 1/8″ to 6″ pipe, in both US Customary and SI metric units.

| NPS (DN) |

SCH No. |

O.D inch mm |

W.T inch mm |

Mass lb/ft kg/m |

| 8 200 |

5S | 8.625 219.1 |

0.109 2.77 |

9.92 14.78 |

| 8 200 |

10S | 8.625 219.1 |

0.148 3.76 |

13.41 19.97 |

| 8 200 |

40S | 8.625 219.1 |

0.322 8.18 |

28.58 42.55 |

| 8 200 |

80S | 8.625 219.1 |

0.500 12.70 |

43.43 64.64 |

| 10 250 |

5S | 10.750 273.0 |

0.134 3.40 |

15.21 22.61 |

| 10 250 |

10S | 10.750 273.0 |

0.165 4.19 |

18.67 27.78 |

| 10 250 |

40S | 10.750 273.0 |

0.365 9.27 |

40.52 60.29 |

| 10 250 |

80S | 10.750 273.0 |

0.500 12.70 |

54.79 81.53 |

| 12 300 |

5S | 12.750 323.8 |

0.156 3.96 |

21.00 31.24 |

| 12 300 |

10S | 12.750 323.8 |

0.180 4.57 |

24.19 35.98 |

| 12 300 |

40S | 12.750 323.8 |

0.375 9.53 |

49.61 73.86 |

| 12 300 |

80S | 12.750 323.8 |

0.500 12.70 |

65.48 97.44 |

| 14 350 |

5S | 14.000 355.6 |

0.156 3.96 |

23.09 34.34 |

| 14 350 |

10S | 14.000 355.6 |

0.188 4.78 |

27.76 41.36 |

| 14 350 |

40S | 14.000 355.6 |

0.375 9.53 |

54.62 81.33 |