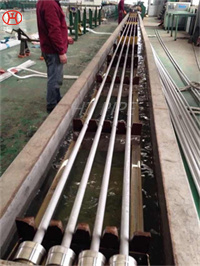

ASME SA789 duplex stainless steel tubes

Duplex 2205 stainless steels are called “duplex” because they have a two-phase microstructure consisting of ferritic and austenitic stainless steel grains. When duplex stainless steel melts, it solidifies from the liquid phase to a fully ferritic structure. As the material cools to room temperature, about half of the ferrite grains transform into austenite grains (“islands”). The result is a microstructure of approximately 50% austenite and 50% ferrite.

2205 is a duplex (austenitic-ferritic) stainless steel containing about 40 – 50% ferrite in the annealed condition. 2205 duplex pipe has been a practical solution to chloride stress corrosion cracking problems experienced with 304/304L or 316/316L stainless pipe. The high chromium, molybdenum and nitrogen contents provide corrosion resistance superior to 316/316L and 317L stainless in most environments. 2205 duplex pipe is not suggested for operating temperatures above 600°F.

The design strength of 2205 duplex pipe is significantly higher than 316/316L, often permitting lighter wall construction. 2205 duplex pipe has good notch impact toughness down to temperatures below – 40°F. 2205 duplex pipe is welded with E2209 or ER2209 fillers.

The yield strength of 2205 duplex pipe is twice that of austenitic stainless steel pipe, a feature that allows designers to reduce weight when designing products, making this alloy more affordable than 316, 317L. Duplex 2205 pipe is a nitrogen-added duplex stainless steel with high strength, good impact toughness and good overall and local stress corrosion resistance. 2205 Duplex Steel is particularly suitable for use in the -50°F/+600°F temperature range. Applications outside this temperature range may also be considered for this alloy.

Duplex 2205 is highly resistant to stress corrosion and chloride cracking. Duplex 2205 is cost effective because it has only 5% Nickel. Duplex stainless has high strength, ductility, toughness and weldability.

| Alloy | UNS | Description |

| 2205 | S31803 | Duplex 2205 is used in environments where resistance to general corrosion and chloride stress corrosion cracking is important. |