ASME SB407 UNS N08810 seamless pipe tube

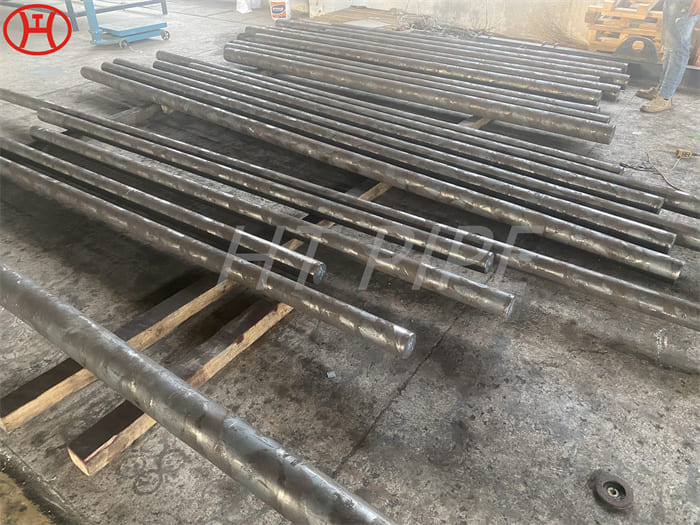

The Incoloy 800h Pipe produced in accordance with the ASTM B407 specification is supplied either in the form of cold worked or hot finished manner. Aside from conforming to the chemistry requirements of the said specification the Sb 407 UNS N08810 Incoloy Alloy 800h Round Pipe, is to be heat treated at determined annealing temperatures. Another requirement that needs to be adhered to is the Sb 407 N08810 Grade 1.4958 Pipe needs to be tested and measured via the Planimetric method.

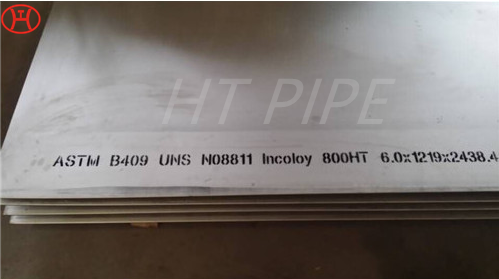

ASME SB 407 Grade 1.4958 Round Pipe, Incoloy 800H Welded Pipe, ASME SB407 Incoloy 800H Pipe

The Incoloy 800h Pipe produced in accordance with the ASTM B407 specification is supplied either in the form of cold worked or hot finished manner. Aside from conforming to the chemistry requirements of the said specification the Sb 407 UNS N08810 Incoloy Alloy 800h Round Pipe, is to be heat treated at determined annealing temperatures. Another requirement that needs to be adhered to is the Sb 407 N08810 Grade 1.4958 Pipe needs to be tested and measured via the Planimetric method.

Incoloy 800H/ HT SCH40 pipe was specially made for high temperature structural applications. The presence of nickel content makes UNS N08810 pipe highly resistant to both chloride stress-corrosion cracking and embrittlement resulted from precipitation of sigma phase. The general corrosion resistance of Incoloy N08810 Exhaust Pipe is excellent. In the solution annealed state, UNS N08810 pipe has better-quality creep and stress rupture properties.

In terms of the UNS N08810 pipe quality, the surface of Inconel 800h Welded Pipe needs to not only be uniform, but it must be smooth and free of injurious defects. Since the Inconel 800h Seamless Pipe is cold drawn, the properties like toughness and hardness tend to be far superior. Hence, the Alloy 800h Pipe can be used in the paper pulp industry. Also, since the Inconel 800h Pipe has good corrosion resistance in many acidic and alkaline environments, ASME SB 407 Inconel 1.4958 Pipe is popular in the petrochemical processing industry as well.

Incoloy WERKSTOFF NR. 1.4958 / 1.4876 Pipe Mechanical Properties

| Alloy | Tensile Stress (MPa) min | Yield Stress 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 800H | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa -205 | 30 | – | – |

ASTM B514 Incoloy 800H Pipe Chemical Composition

| Grade | C | Mn | Si | Fe | S | Cr | Al-Ti | Ni |

| minimum | 0.05 | – | – | 39.5 | – | 19.0 | 0.15 | 30.0 |

| maximum | 0.1 | 1.5 | 1.0 | – | 0.015 | 23.0 | 0.60 | 35.0 |