ASTM A105 CARBON STEEL SOCKET WELD FITTING ASME SA105 SOCKETWELD FITTING

ASTM A105 Forged Fittings for various right industrial solutions. The product to the domestic and global patrons is offered at most attractive rates. The product is manufactured in accordance with various raw materials standard qualities. They are enjoying having a good reputation in the market.

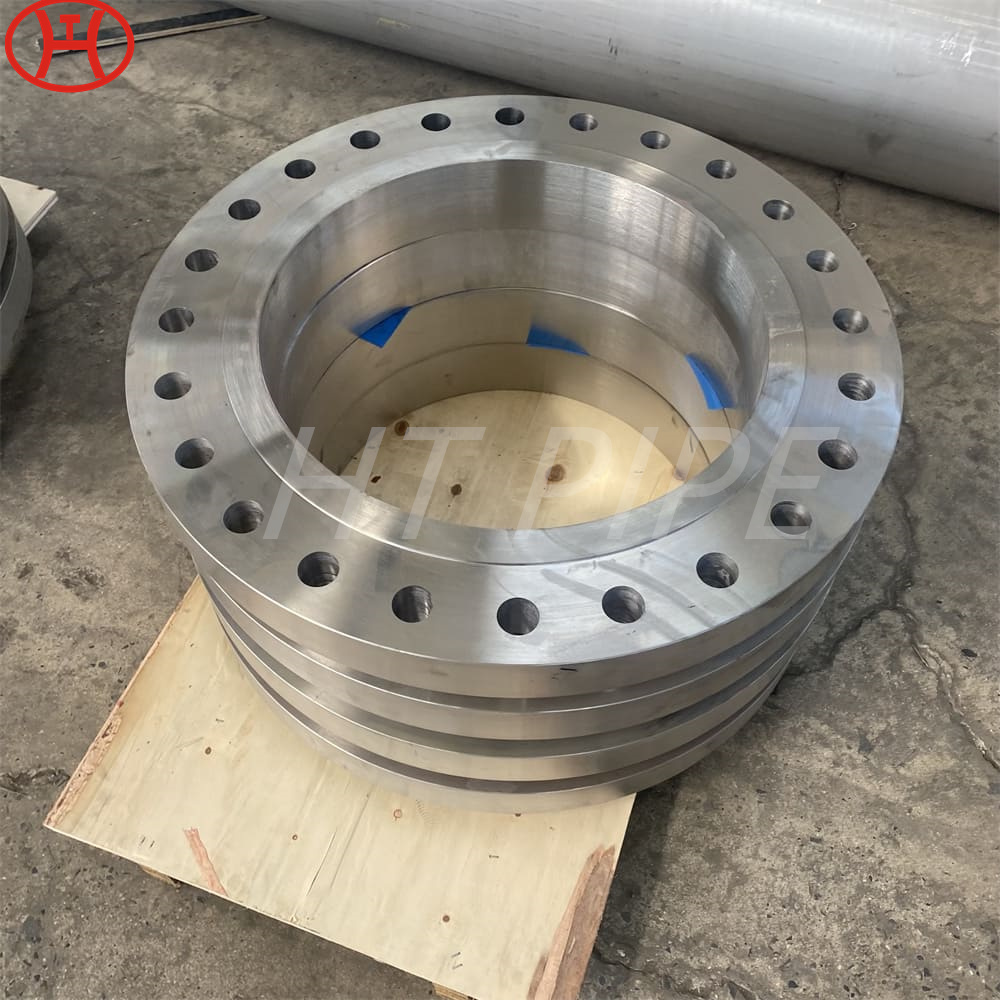

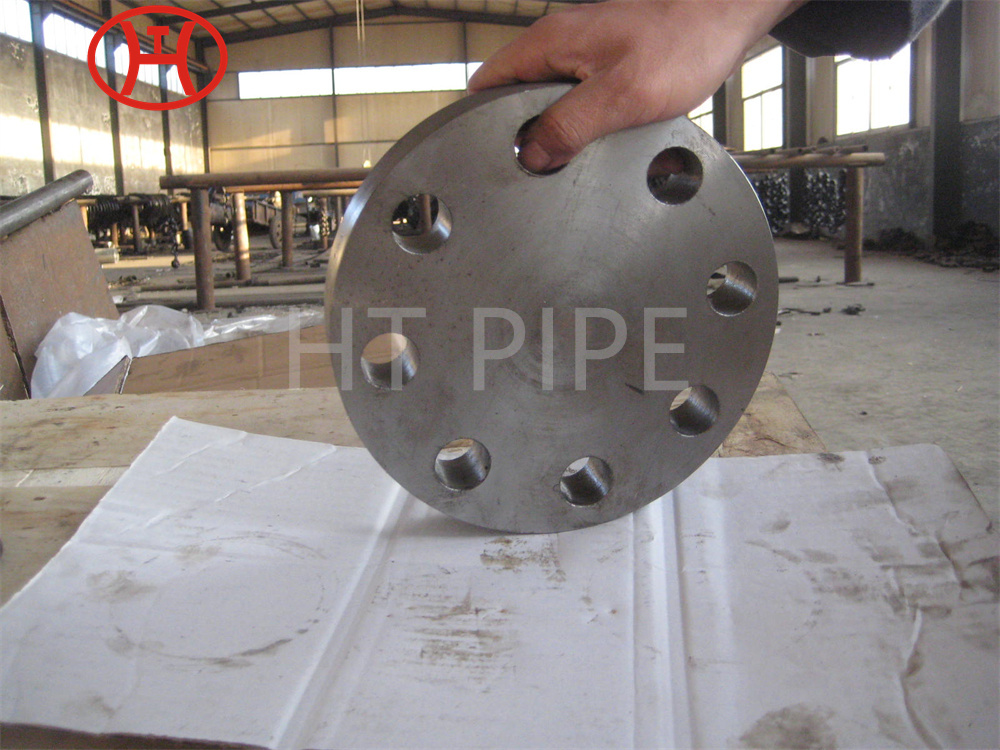

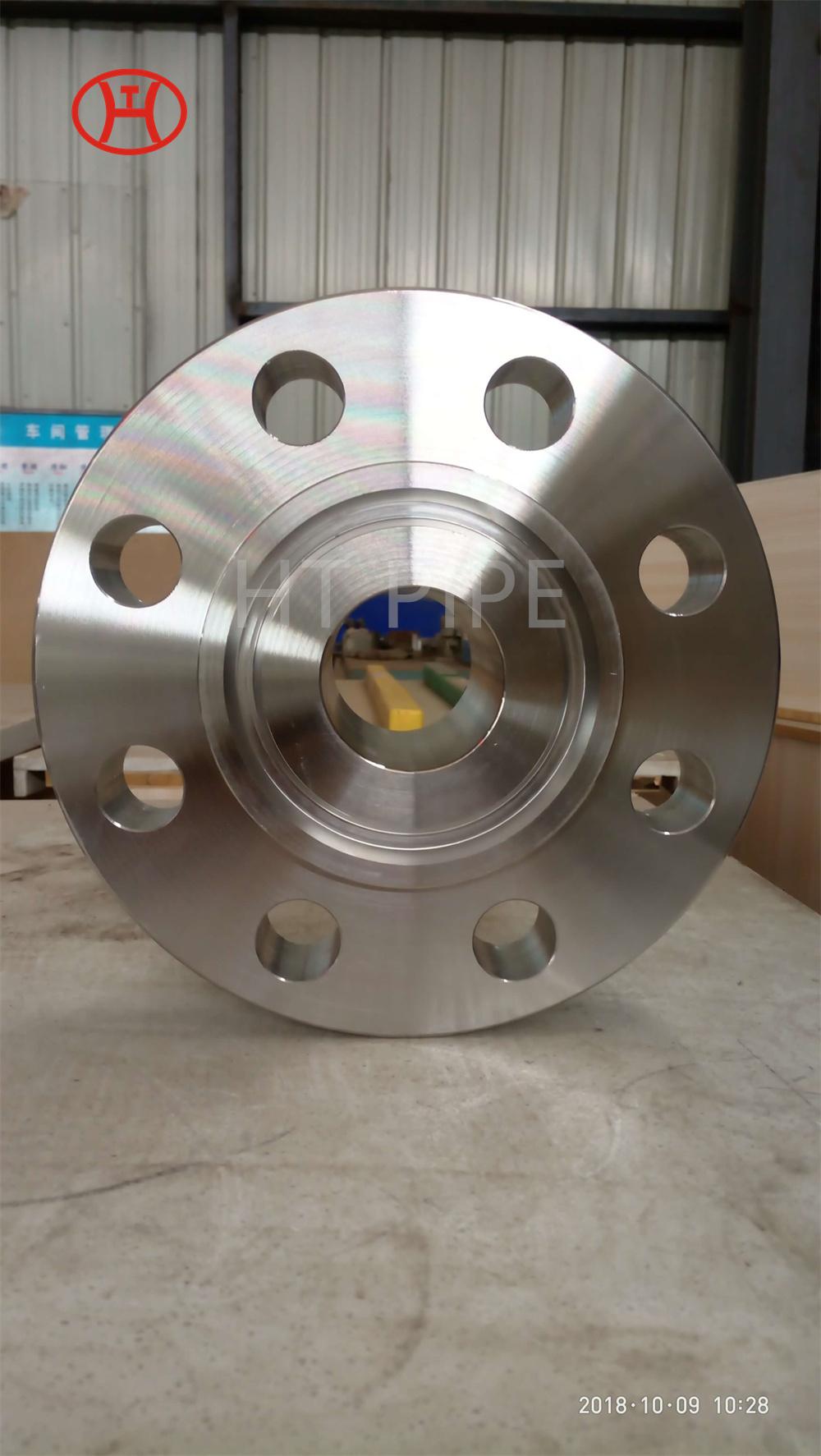

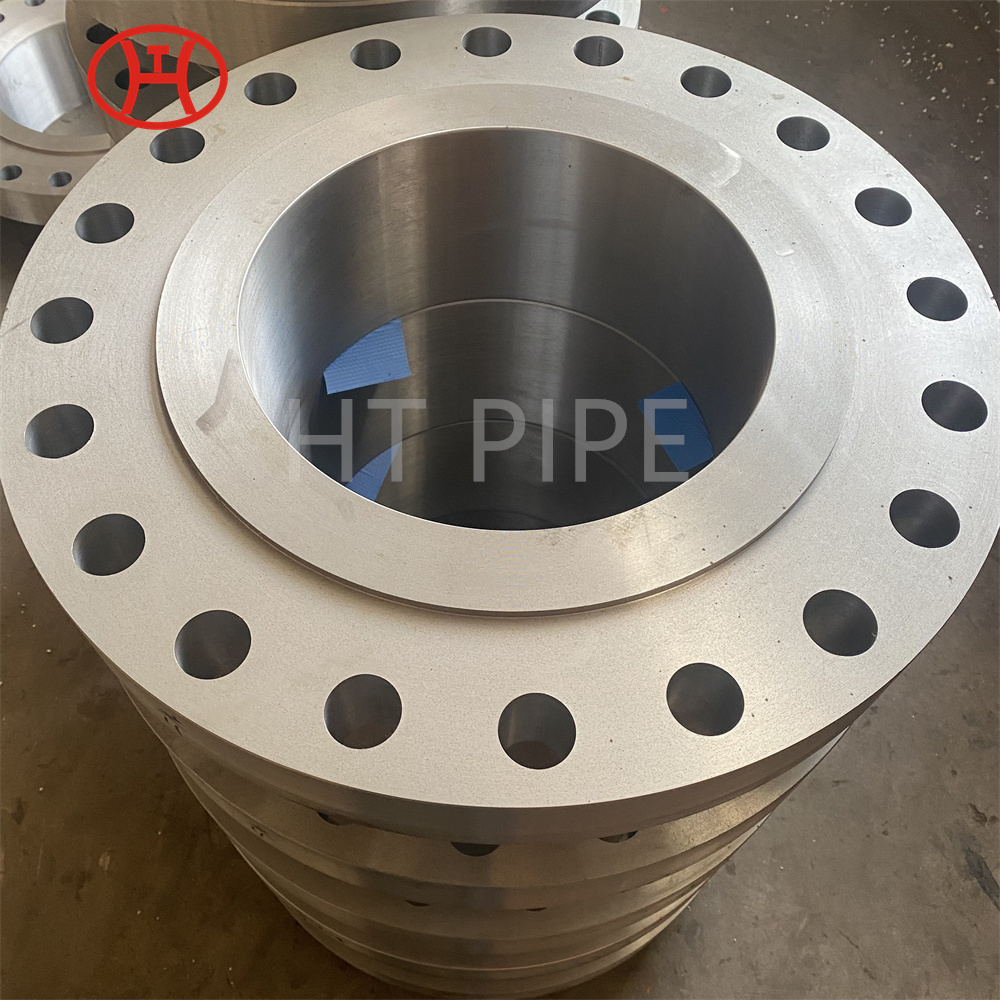

Carbon Steel A105 Street Elbow, ASTM A105 Carbon Steel Bushing, A105 Carbon Steel Equal Tee, Carbon Steel Forged Socketweld Fitting, Carbon Steel A105 Forged Elbow, Carbon Steel SA105 Pipe Nipple Supplier

Since there are different carbon steel alloys available in the market, Carbon Steel A105 Street Elbow is possible to classify them based on their performance at varying temperatures. For instance, the use of Carbon Steel ASTM A105 Fittings is prominent in those applications that involved not only environments where the temperatures are high, but also in those applications at room temperature. Usually, these applications are pressure systems, and ASTM A105 Carbon Steel Bushing is seen in many instances, the ASTM A105 Threaded Fittings add value to said application. Firstly, the entire setup cost of the application sees a drastic reduction. Next, the toughness and hardness properties of the Sa 105 Fittings work in favor of the pressure systems, as they need a durable fitting to withstand the force of media flow. And even though the corrosion resistance properties of the ASTM A105 Socket Weld Fittings are very low, there are certain processes that are used by manufacturers to bring about a change in them. Galvanization, chrome plating, or electroplating with a coat of zinc are processes that increase the corrosion resistance behavior of the ASTM A105 Pipe Fittings.

Typical to most specifications, the heat furnishing techniques have been detailed in the ASTM A105 as well. The heat treatment furnished on the ASTM A105 Forged Fittings includes annealing, normalizing as well as tempering, or quenching. The primary purpose of heat treatment like these is the elimination of residual stresses and the removal of unwanted elemental residues by purifying the Carbon Steel A105 Pipe Fittings. Carbon steel fittings are cheap and they have good toughness, yet they lack significant corrosion resistance properties. Hence, A105 Carbon Steel Equal Tees are frequently galvanized or Carbon Steel Forged Socketweld Fittings may be coated by surface treatments like painting or electroplating with zinc. When residual stresses aren¡¯t eliminated from the ASTM A105 Fittings, Carbon Steel A105 Forged Elbows are most likely to crack on failure, rendering them useless. Hence, Carbon Steel SA105 Pipe Nipple is highly recommended to use heat treatments on these fittings. Forging the fittings improves the alignments of the grain in the alloy of Forged A105 Weld Fitting, making ASTM A105 Socket Weld Half Coupling straighter and giving its microstructure a more uniform appearance. Moreover, the surface of the ASTM A105 Socket Weld Bushing is smoother as well. CS A105 Threaded Fittings under this specification could not only be repaired by welding but also retreated and marked per the given guidelines.

Carbon Steel Forged Fittings Manufacturing Standards :asme b16.11

| ASTM A105 – ASME SA105 | Standard Specification for Wrought Austenitic Carbon Steel Piping Fittings |

| ASME B16.11 | Socket Welding and Threaded Forged Fittings |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |