Home » Forged Flanges » ASTM A182 316L spacer ring more capable to operate in corrosive atmospheres

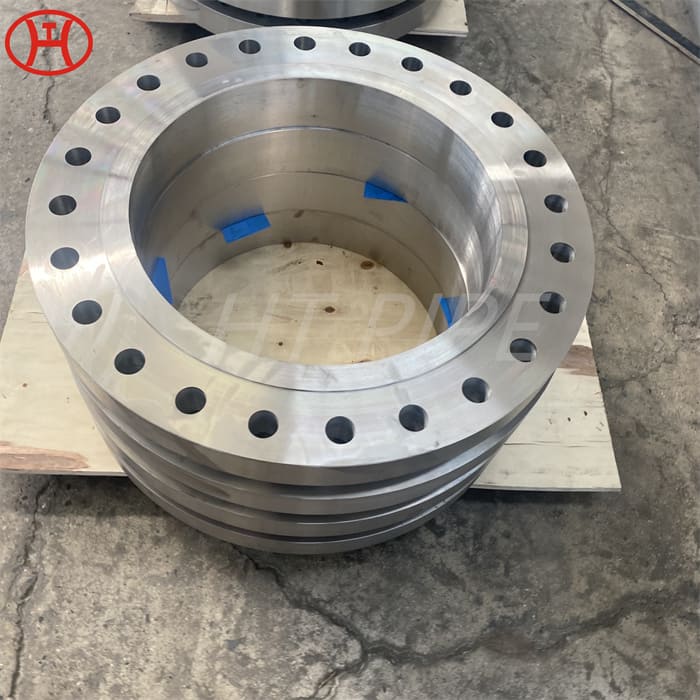

ASTM A182 316L spacer ring more capable to operate in corrosive atmospheres

Stainless steel 316/ 316L flanges can be made by hot forging or casting. Blind or sliding plate flanges without hubs can be machined directly from the plate. Flanges should be solution treated at not less than 1900¡ãF [1040¡ãC] and then quenched in cold water or other rapid cooling method.

Contact US

Get Price

Share:

Content

It is widely used for heavy welded parts (about 6mm and above). The higher carbon grade 316H can be used at elevated temperatures, as is the stable grade 316Ti. The synthetic composition of 316 provides steel with improved corrosion resistance in many corrosive environments. In addition to connecting pipes, stainless steel 316L flanges are also used to connect valves, pumps and other equipment in piping systems.

Inquiry

More Stainless steel