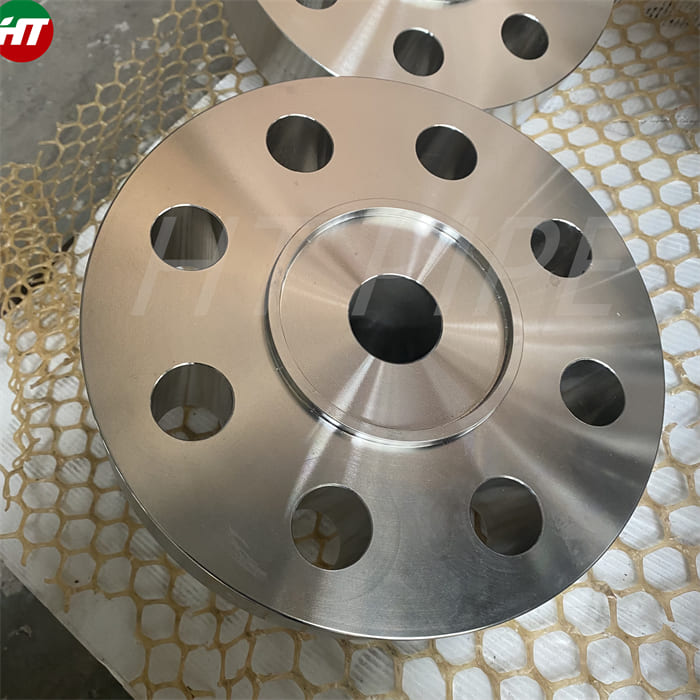

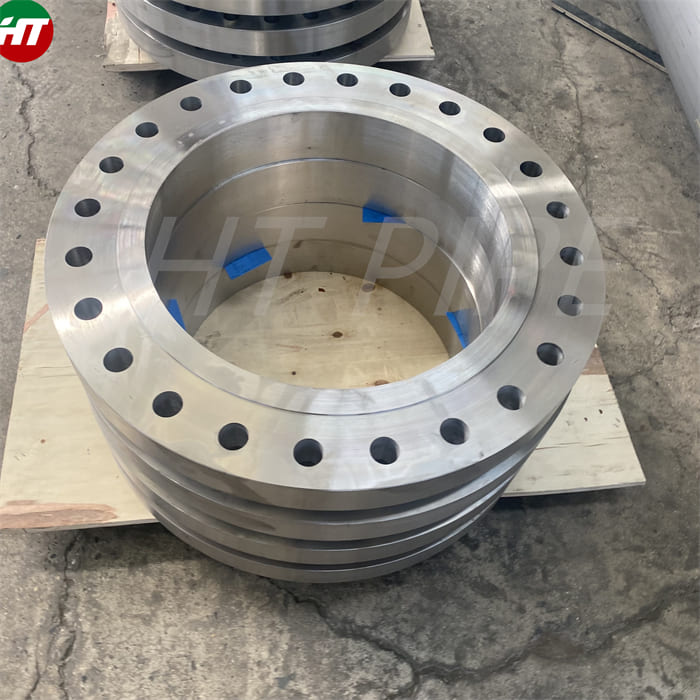

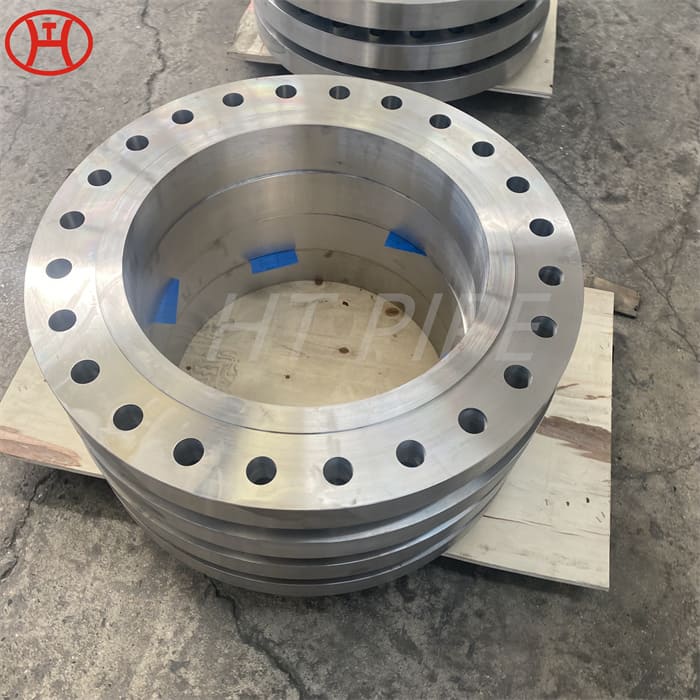

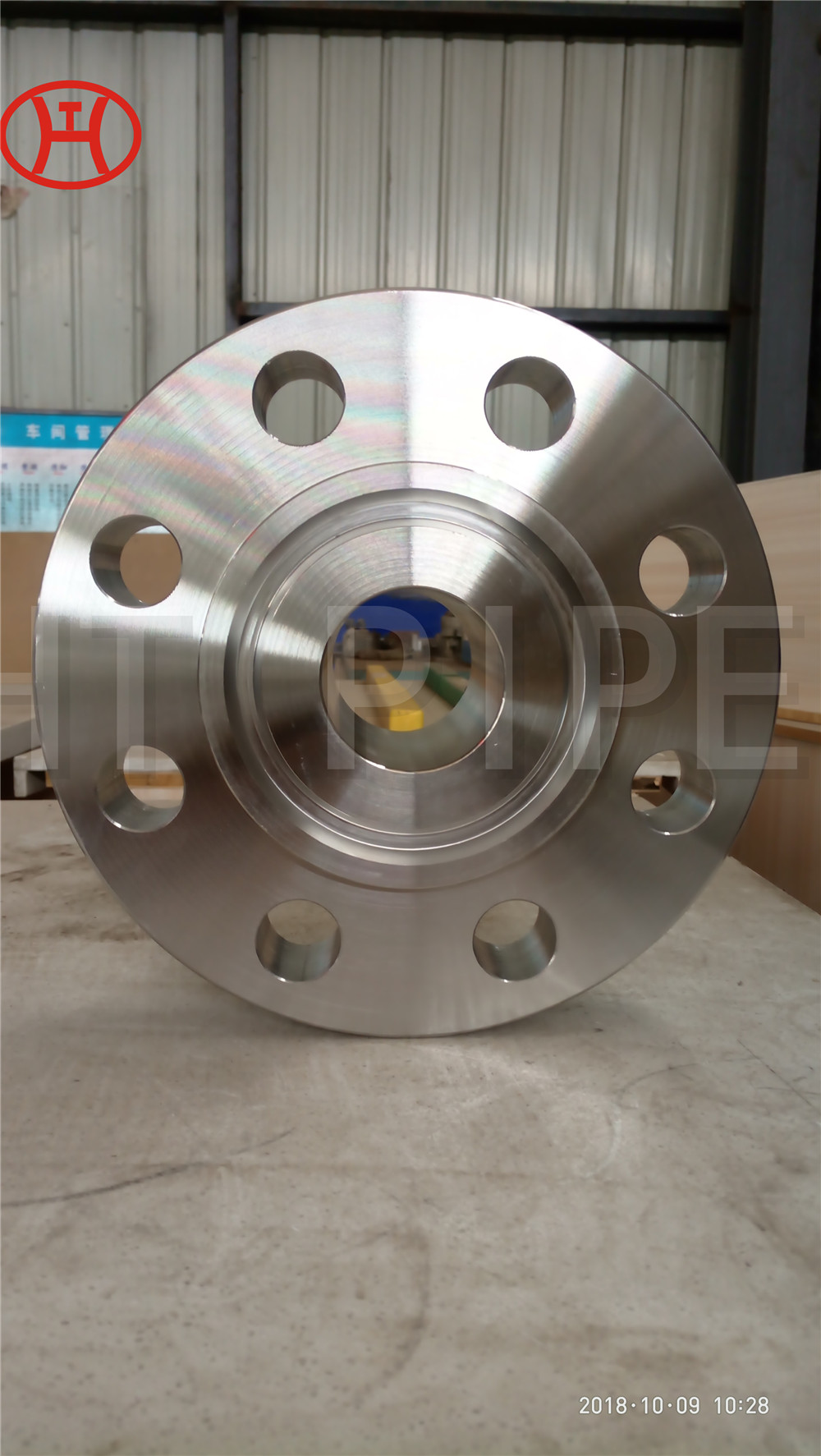

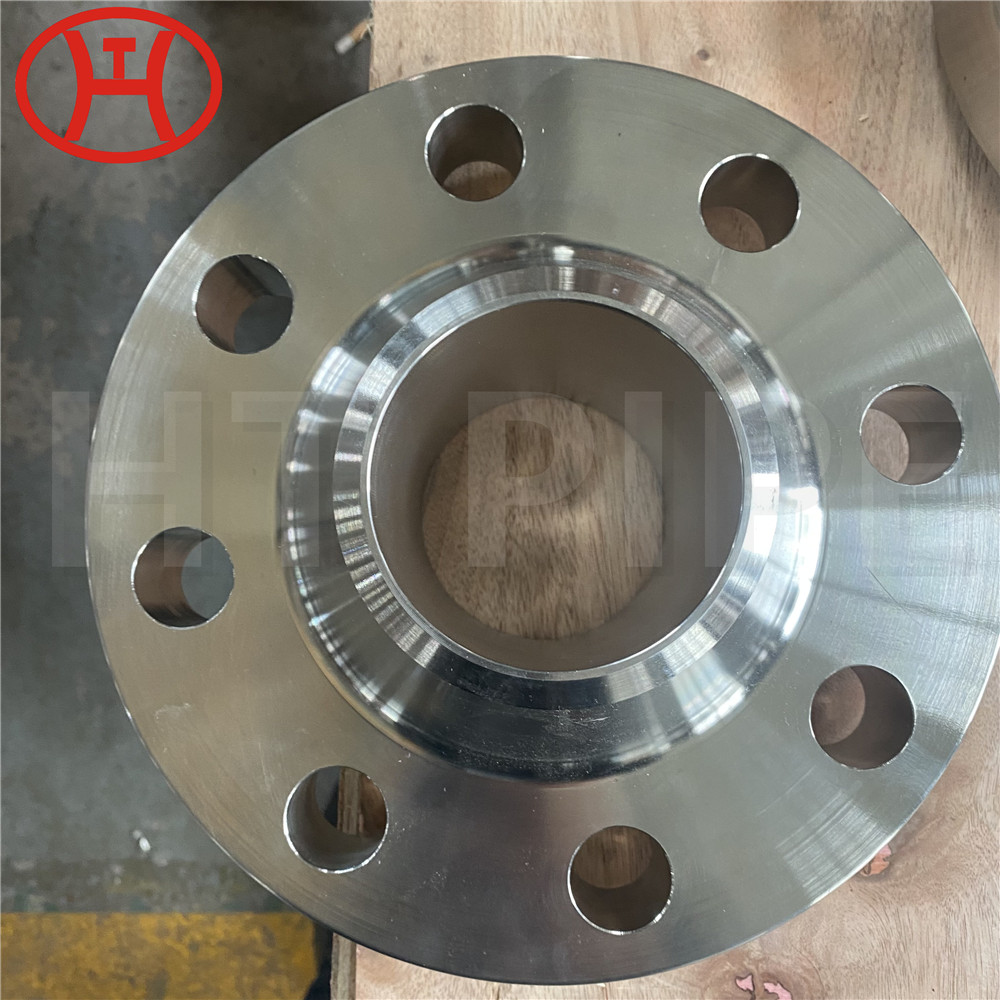

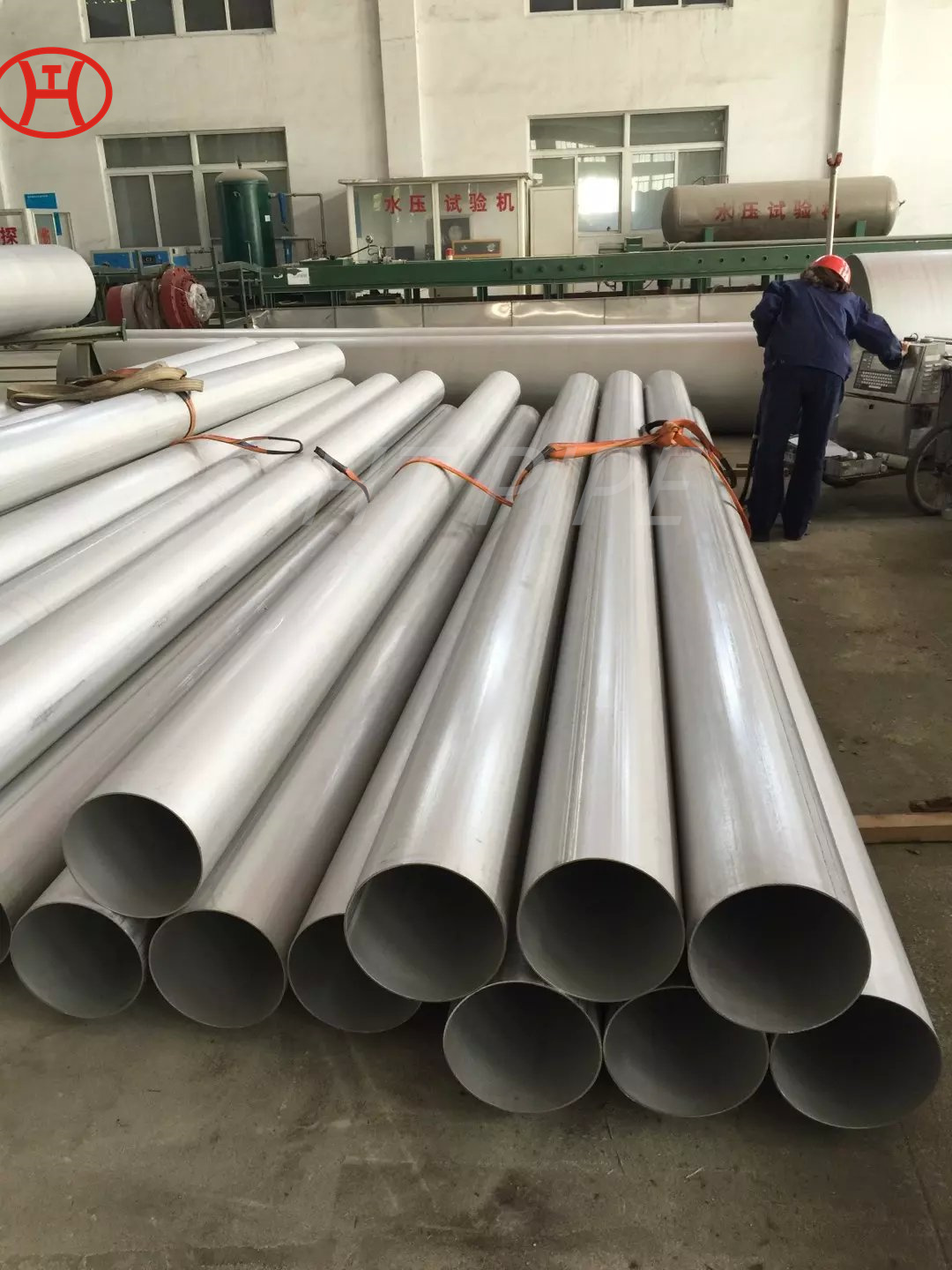

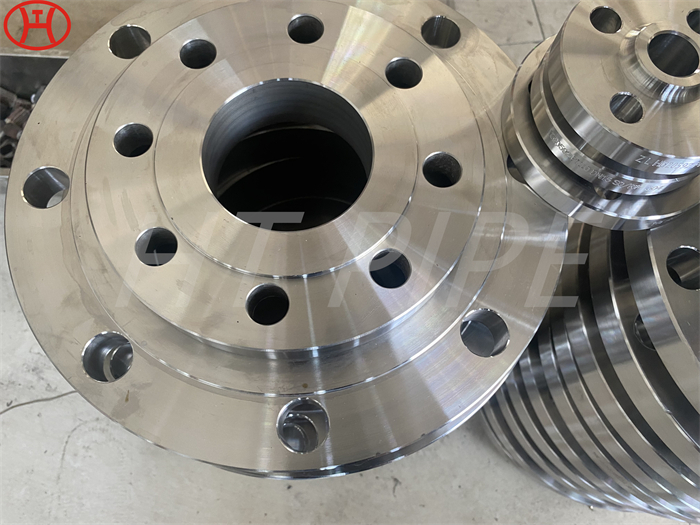

ASTM A182 F304 304L 304H Stainless Steel Flange

The flange is second most used joining method after selding. Flanges are used when joints need dismantling. It provides flexibility for maintenance. Flange connects the pipe with various equipment and valves. Breakup flanges are added in the pipeline system if regular maintenance in required during plant operation.

Stockist of SS 304L Slip On Flanges, SS UNS S30403 Pipe Flanges, Global Supplier of SS 304L Weld Neck Flange, SS F304L Flange, Stainless Steel 304L Flanges, SS 304L Blind Flanges Dealer in China, ANSI B16.5 SS 304L Orifice Flanges, BS10 Table D, Table E, DIN Standard Flanges.

The Stainless steel 304 flanged joint is composed of three separate and independent although interrdlated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls are required in the selection and application of all there elements to attain a joint, which has acceptable leak tightness.

The Stainless steel 304 flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength (as the flange of an iron beam such as an I-beam or a T-beam); for easy attachment/transfer of contact force with another object (as the flange on the end of a pipe, steam cylinder, etc., or on the lens mount of a camera); or for stabilizing and guiding the movements of a machine or its parts (as the inside flange of a rail car or tram wheel, which keep the wheels from running off the rails). The term “flange” is also used for a kind of tool used to form flanges.

Stainless steel 304/ 304L flanges may be manufactured in accordance with ASME B16.5 or ASME B16.47 with nominal composition of 18Cr-8Ni. The low-carbon versions of the 304 stainless steel. The flanges may be made from forgings, castings, or plates covering various types and classes of ASME B16.5 and ASME B16.47 (both Series A and Series B). Stainless steel 304/ 304L flanges of ASME B16.5 are available in Classes 150, 300, 400, 600, 900, 1500, 2500; that of ASME B16.47 Series A are available in Classes 150, 300, 400, 600, 900; that of ASME B16.47 Series B are available in Classes 75, 150, 300, 400, 600, 900.

304L Flange is the most versatile and widely used of all stainless steels. Its chemical composition, mechanical properties, weldability and corrosion/oxidation resistance provide the best all-round performance stainless steel at relatively low cost. It also has excellent low-temperature properties and responds well to hardening by cold working. If the potential for intergranular corrosion in the heat-affected zone exists, 304L is recommended.

Chemical Composition of Grade F304L Stainless Steel Pipe Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

Mechanical Properties of ASTM A182 SS 304L Plate Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |