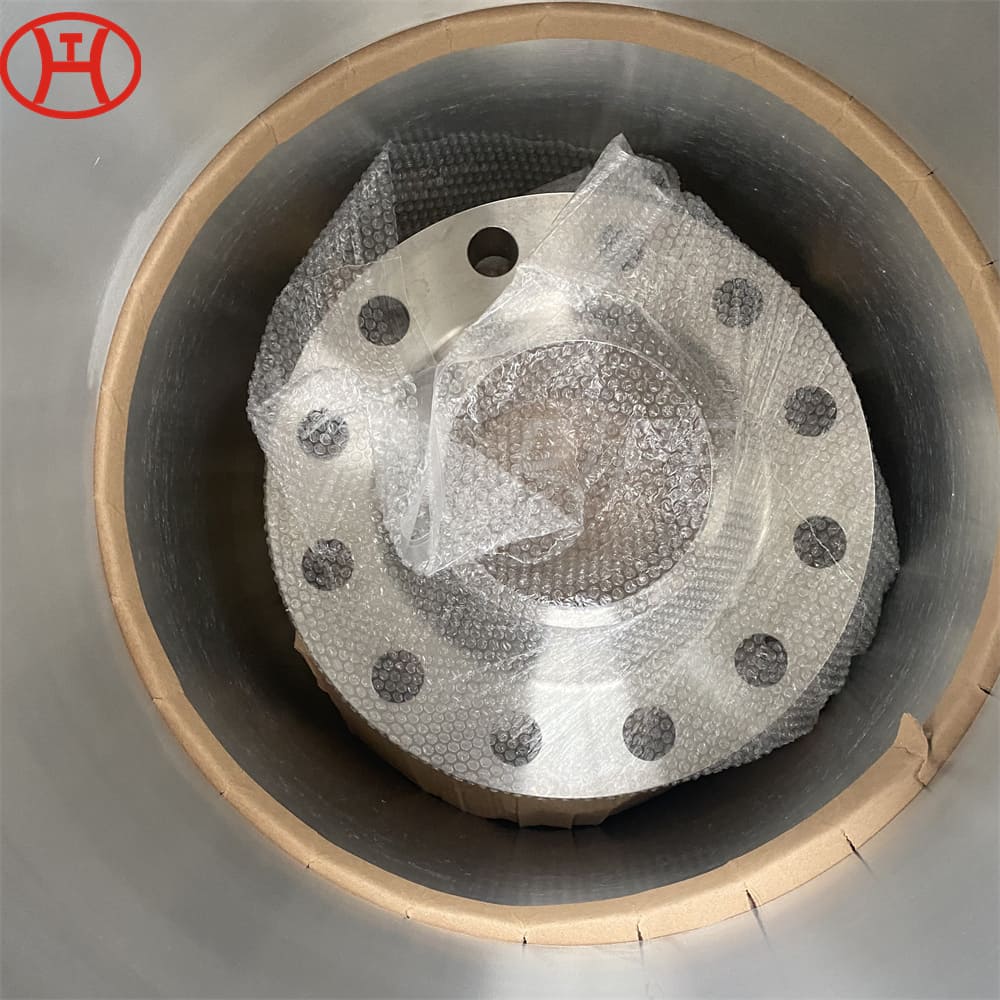

ASTM A182 F304 SO Flanges Low-Pressure 304 Stainless Steel Forged Pipe Flange

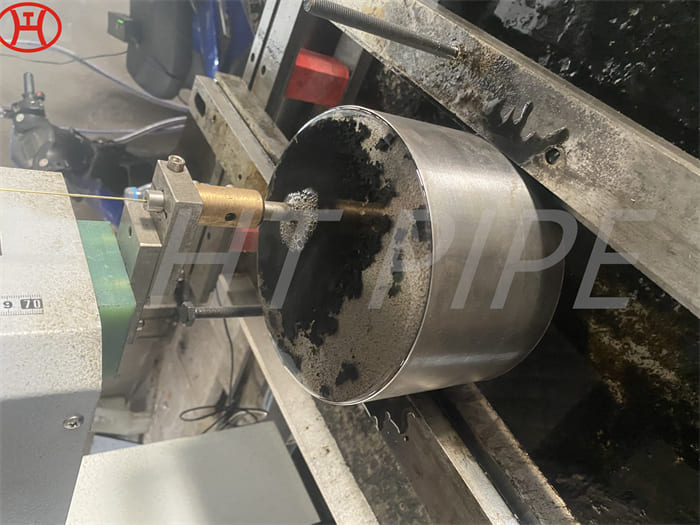

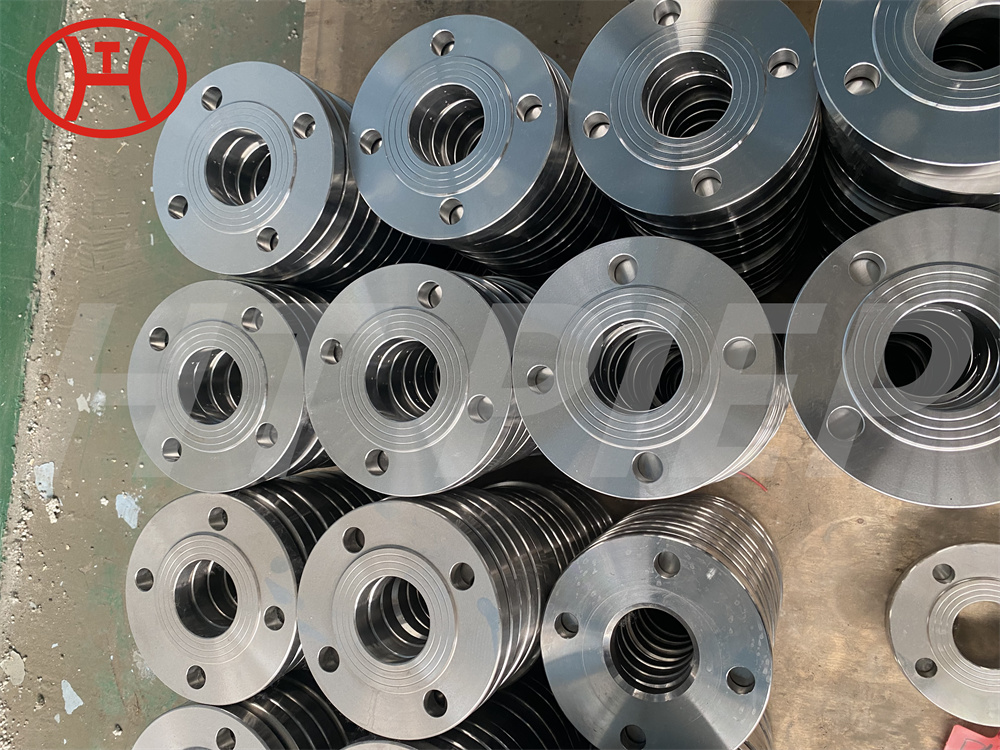

The installation process for a 304 stainless steel SO flange is relatively simple. Firstly, the pipe end is prepared by cleaning it and ensuring that 1.4301 flange is free from damage and debris. Next, the S30400 flange is positioned on the pipe and aligned to ensure a smooth flow of the fluid or gas. Finally, the bolts are tightened to the manufacturer’s specifications to ensure a secure connection, taking care not to overtighten the bolts as this can cause damage to the flange or pipe.

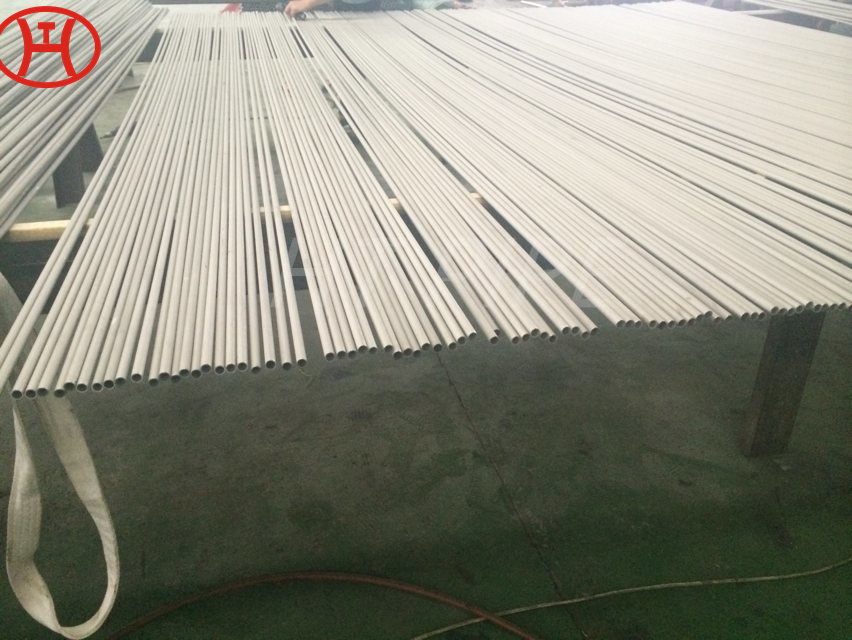

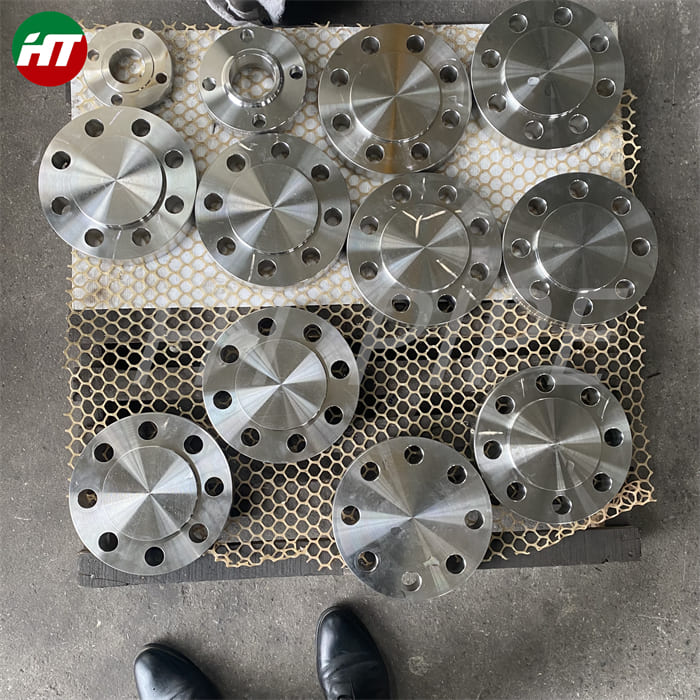

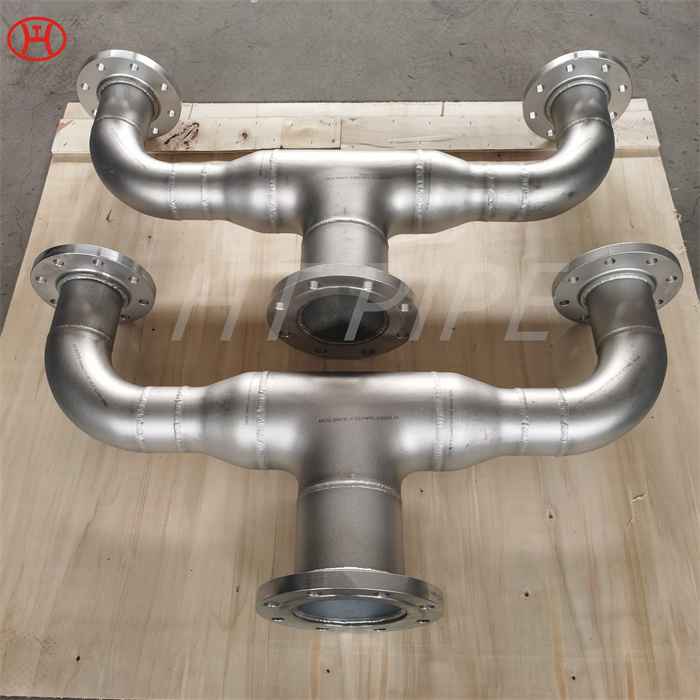

ASTM A182 F304 Flanges, Low-Pressure 304 Stainless Steel Forged Pipe Flange, 304 Stainless Steel Forged Pipe Flange, SS 304 Flange, MSS SP-44 SS 304 Pipe Flange, UNS S30400 Flanges, Class 150 UNS S30400 Flanges, Stainless Steel 304 Slip On Flange Manufacturer.

The installation process for a 304 stainless steel SO flange is relatively simple. Firstly, the pipe end is prepared by cleaning it and ensuring that 1.4301 flange is free from damage and debris. Next, the S30400 flange is positioned on the pipe and aligned to ensure a smooth flow of the fluid or gas. Finally, the bolts are tightened to the manufacturer’s specifications to ensure a secure connection, taking care not to overtighten the bolts as this can cause damage to the flange or pipe.

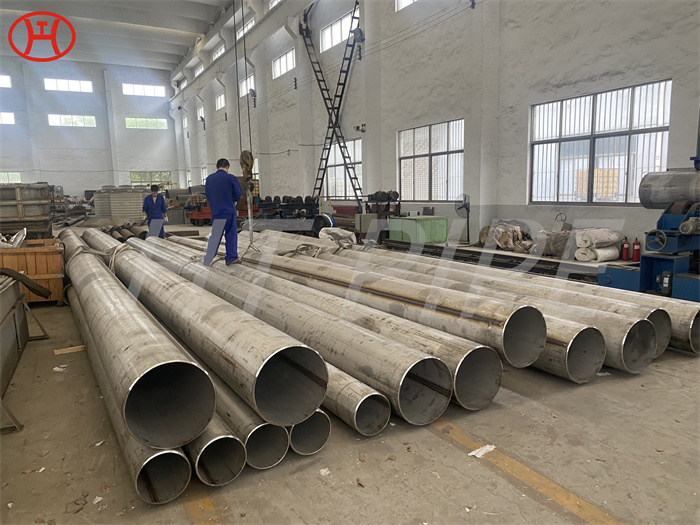

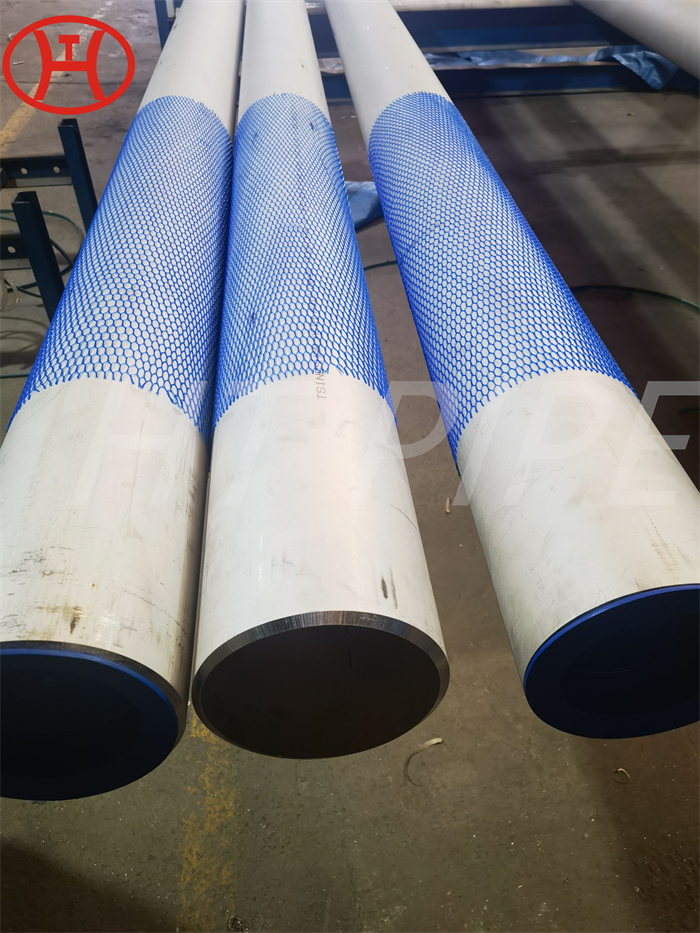

Benefits of using the ASTM A182 F304 Flange include its corrosion resistance, durability, and versatility. SUS 304 SO flange is suitable for use in a wide range of temperatures and pressures, making SS 304 Slip On Flange an ideal choice for many industrial applications. Additionally, the availability of different grades of stainless steel allows for flexibility in choosing a flange that meets specific requirements for a particular application.

The Low-Pressure 304 Stainless Steel Forged Pipe Flange is a reliable and durable component that plays an important role in connecting pipes, valves, and fittings together in a piping system. Its corrosion resistance, easy installation, and cost-effectiveness make UNS S30400 Flange a popular choice in a variety of industries. Choosing the right flange for a specific application plays a crucial role in the smooth operation and longevity of a piping system.

ASTM A182 F304 Chemical Composition

| Gr. | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| Stainless Steel 304 Flanges | Minimum | – | – | – | – | – | 18.0 | – | 8.0 | – |

| Maximum | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||

A182 F304 Mechanical Properties

| Grade | Tensile Strength (MPa) miniimum | Yield Strength 0.2% Proof (MPa) miniimum | Elongation (% in 50mm) miniimum | Hardness | |

| Rockwell B (HR B) maximum | Brinell (HB) maximum | ||||

| Stainless Steel 304 Flanges | 515 | 205 | 40 | 92 | 201 |