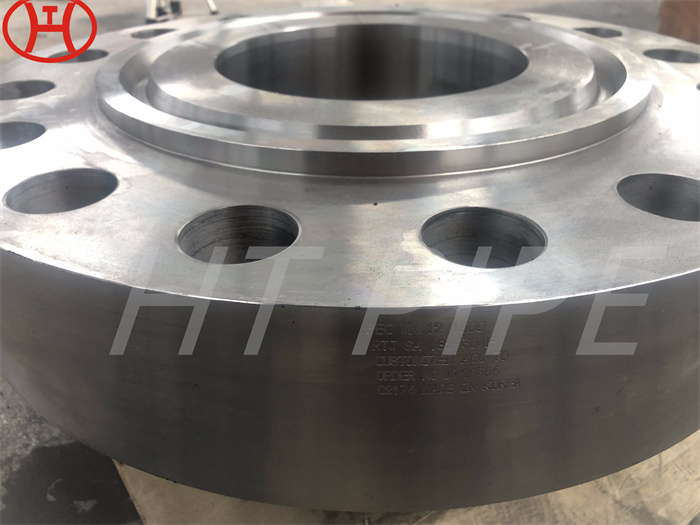

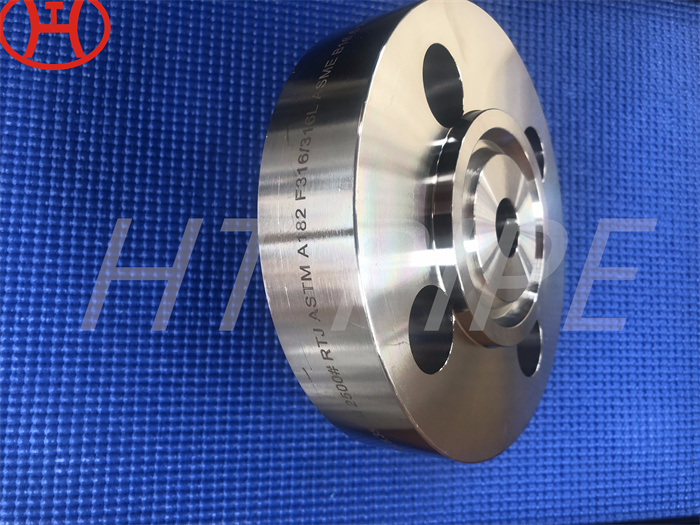

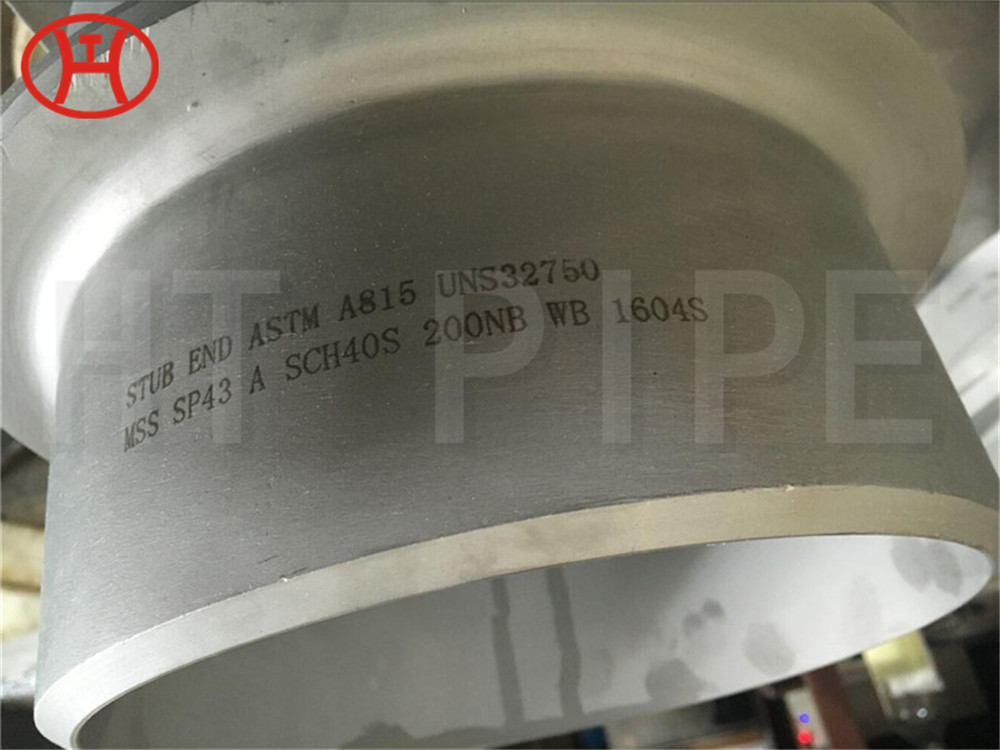

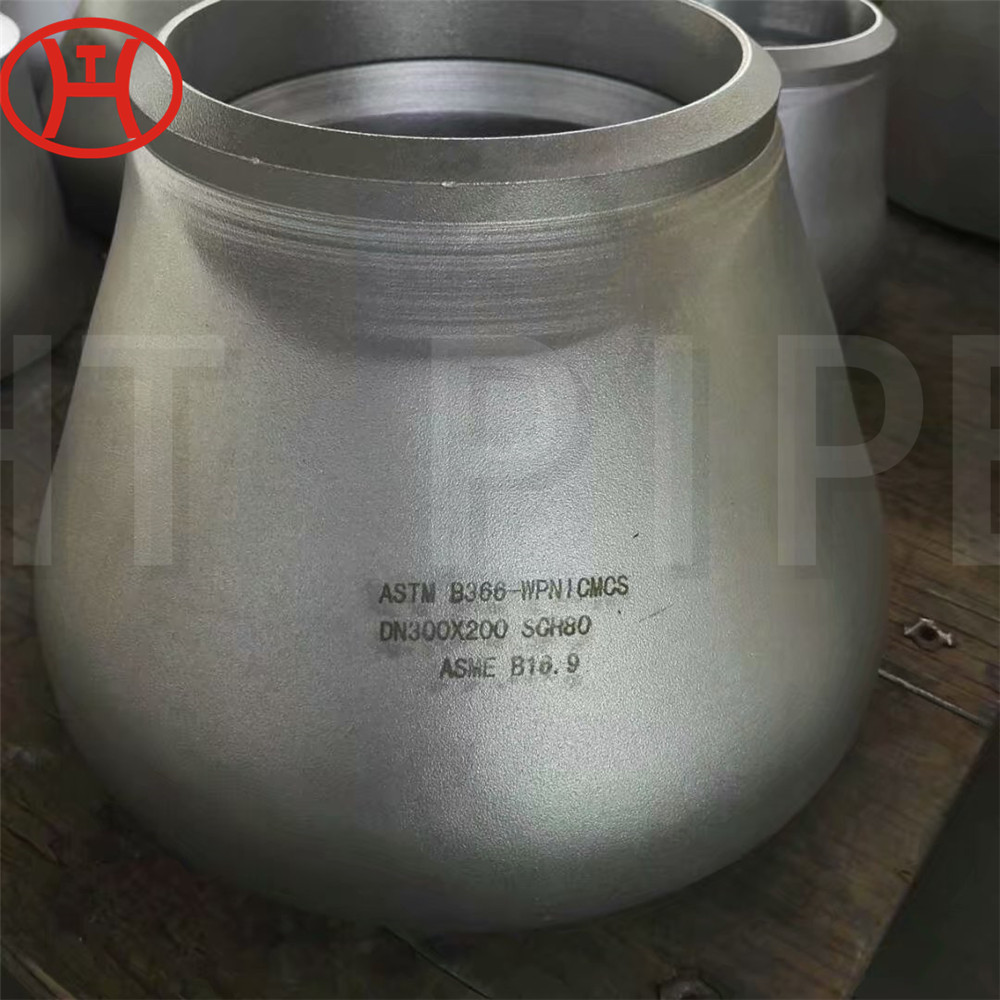

ASTM A182 F5 F9 F11 F12 F22 F91 Flanges offers good corrosion resistance

The flange connection type usually comes with double units, with a gasket and some bolts & nuts to connect each other. (Firstly pipes are welded on the flanges, then valves and other equipment could be installed on flanges.)

The inclusion of molybdenum and chromium in its alloy ensures better mechanical properties and some level of resistance to corrosion. The ASTM SA182 F11 cl 2 Blind Flange is one of the types which is used for a special purpose. Unlike other flanges, the blind flanges close the connections by ending a pipe line. F1 steel Plate Flange is often a cost effective solution, when raised faces and hubs are not required and for the applications with no or low pressure at ambient temperatures. When they are exposed to high temperatures, astm a182 f22 class 3 flange offer good resistance to atmospheric corrosion and some resistance to the effects of scaling. Molybdenum added in alloys is usually associated with high stiffness and hardness.