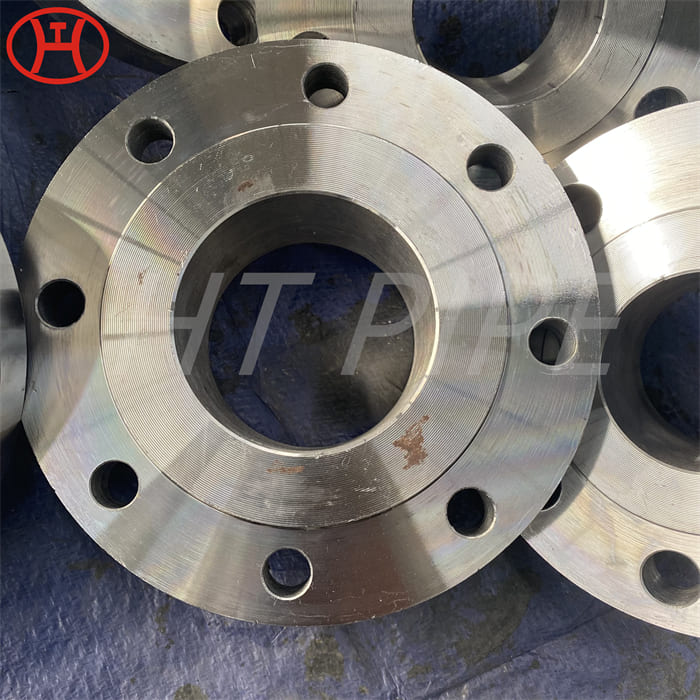

ASTM A182 SMO 254 WN Flange Manufacturer SMO 254 UNS S31254 Slip On Flanges Stockist

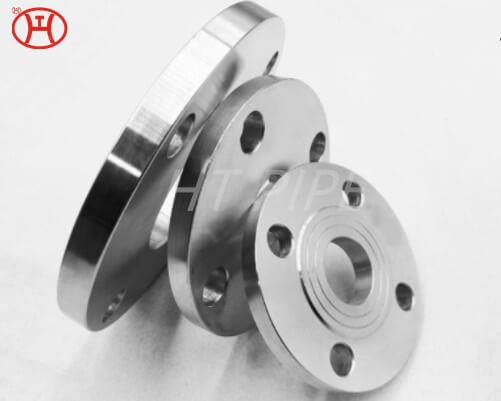

Grade SMO 254 Long Weld Neck Flanges are thermally stable and possess moderate strength even when the temperature is high. SMO 254 Threaded Flanges whose design enables combining improved resistance to pitting, high strength, stress corrosion, crevice corrosion, and cracking.

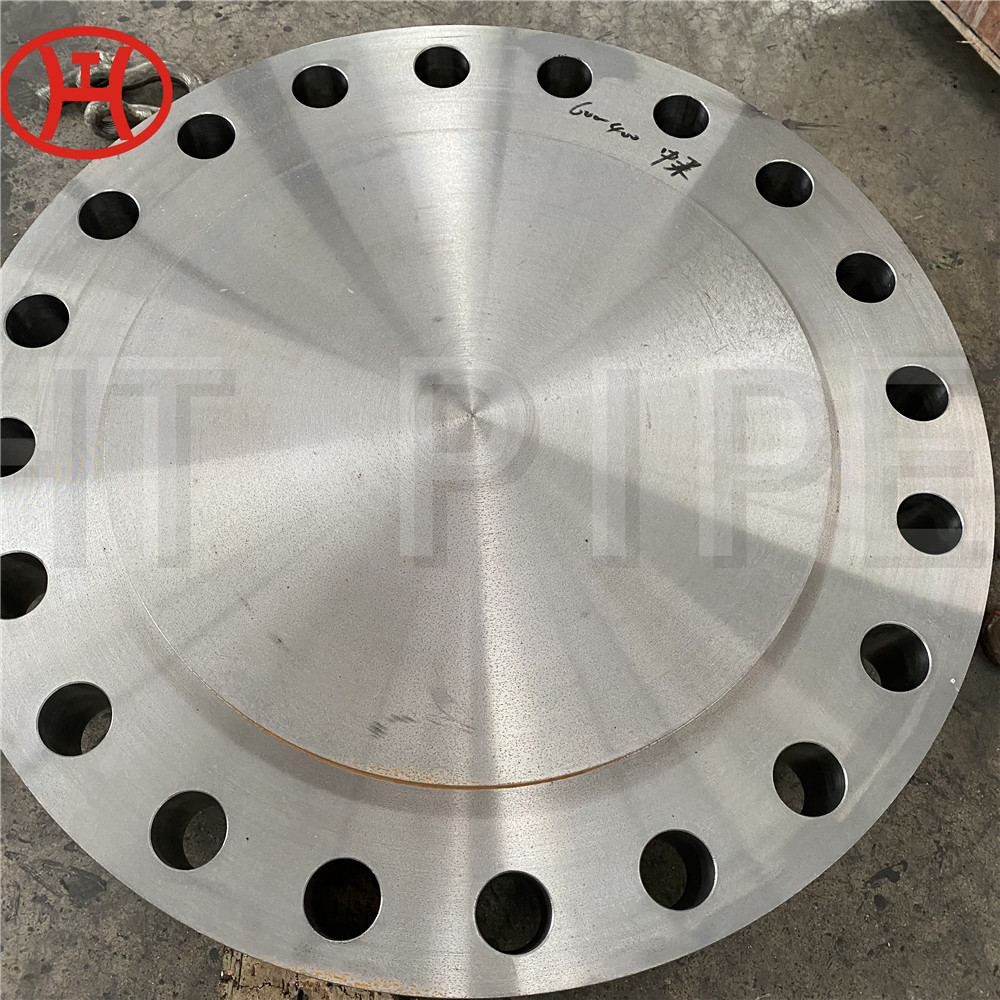

ANSI B16.5 SMO 254 Ring Type Joint Flanges, SMO 254 Industrial Flanges Stockholder, SMO 254 Spacer, ASME SA182 SMO 254 Lap Joint Flange, SMO 254 Spade Flange, SMO 254 Screwed Flanges Stockist, SMO Grade 254 Forged Flanges Manufacturer.

ASTM A182 SS 254 SMO Flanges is an austenitic stainless steel designed for maximum resistance to pitting and crevice corrosion. Due to its high initial yield strength, Stainless Steel UNS S31254 Flanges will require greater force than used in other austenitic stainless steels. Grade WNR 1.4547 Flanges is often used in Pulp and Paper Industry, such as for bleach plant, vats, drums, press rolls, piping, etc. In new construction, ASME SA 182 Stainless Steel 254 SMO Flanges has been found in many cases to be a technically adequate and much less costly substitute for nickel-based alloys and titanium. Buy 254 SMO Stainless Steel Flanges at cost-effective rates from us. Due to high levels of molybdenum and nickel content in the alloy, most Uns S31254 Super Duplex Stainless Steel Flanges Suppliers suggest that buyers use this alloy in high chloride environments. Examples of applications as recommended by the 254 Smo Flanges Manufacturer In India include: Saltwater handling, Desalination equipment, Petroleum production, Pulp mill bleach systems, Tall oil distillation columns, Food and chemical processing equipment, Flue gas desulphurization scrubbers, Offshore oil & gas production equipment etc. Since the process used to manufacture the UNS S31254 Weld Neck Flange has been done by advanced machines, the components, parts or equipments manufactured from this alloy will attain a high surface finish as well as dimensional accuracy.

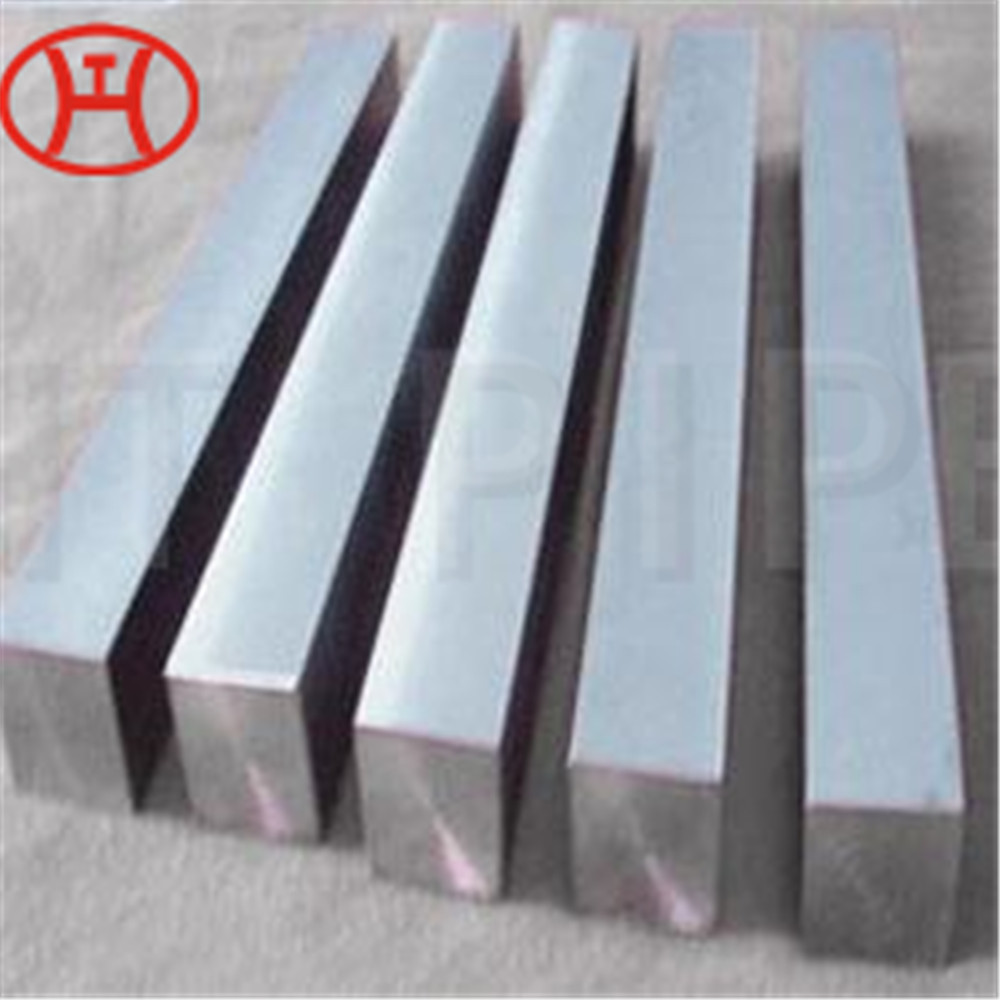

SMO 254 Flanges belong to the ASTM A182 specification with sizes ranging from 1/2 inches to 48 inches. There SMO 254 Spectacle Blind Flanges are different standards to govern the dimensions such as ASME, ANSI, DIN and other international standards. The UNS S31254 Pipe Flange is made under different production types such as the forged, screwed, threaded and plate flanges. There are also different functional types such as slip on flanges, lap joint flanges, orifice flanges, welded neck flanges and blind flanges. The ANSI B16.5 SMO 254 Ring Type Joint Flanges come in different types such as the SMO 254 Spectacle Blind Flange as well. Each different type of flange has a purpose to serve in an application. The face type of the flanges vary as well. There are raised face, flat face and ring type joint face types of flanges ranging from pressure classes 150 through 2500. The 6mo Plate Flange and other flanges are made from a chromium, nickel, molybdenum alloy. The material has 19% chromium, 17% nickel, 6% molybdenum with carbon, manganese, silicon, copper, sulfur and sulfur in it. The different types of flanges such as the 254 SMO Slip on Flange have good corrosion resistance due to the composition. The SMO 254 Industrial Flanges are also stronger than the ordinary stainless steel flanges with 650MPa minimum tensile strength, 300MPa minimum yield strength and 35% elongation rate.

SMO 254 Pipe Flanges Chemical Composition

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20.5 |

SMO 254 Plate Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |

Equivalent Grades for 254 SMO Industrial Pipe Flanges

| STANDARD | WERKSTOFF NR. | UNS | SIS | BS | GOST | AFNOR | EN |

| SMO 254 | 1.4547 | S31254 | 2378 | – | – | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |