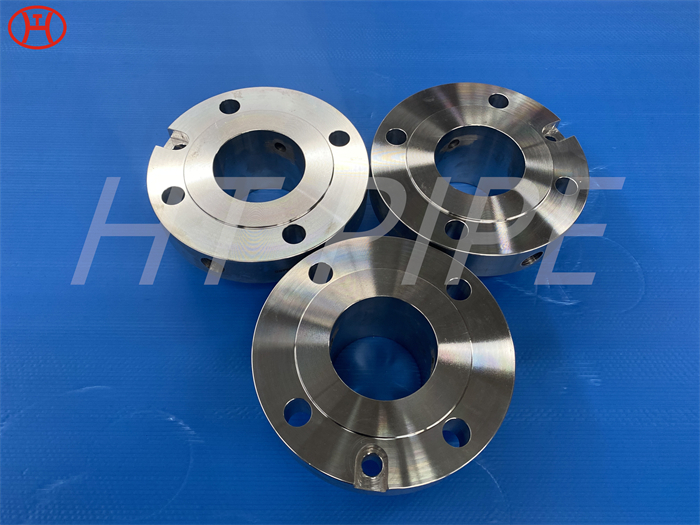

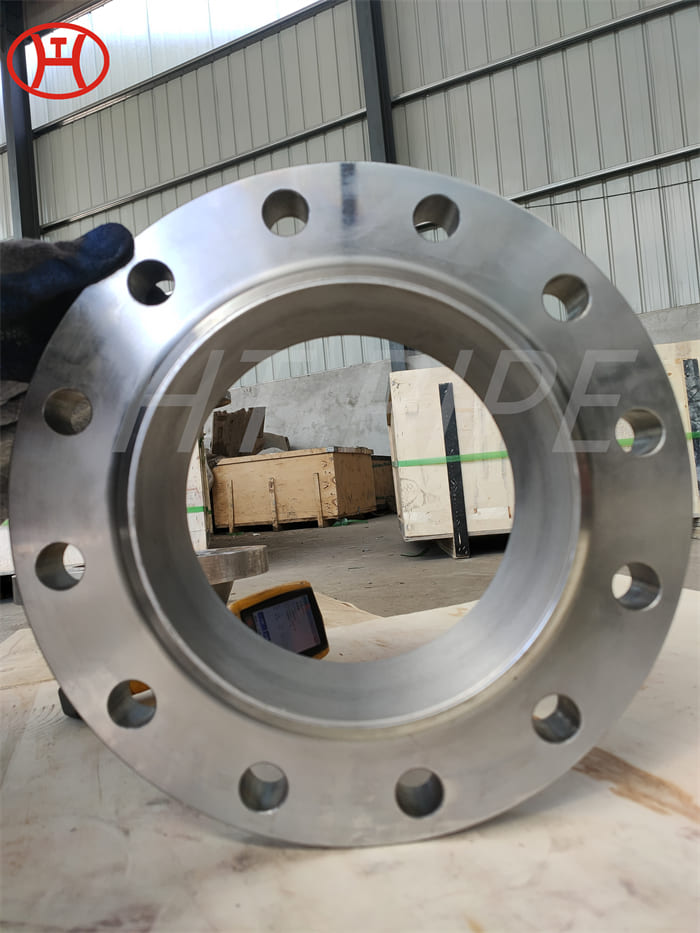

ASTM A182 Stainless Steel 310 Flanges Types Chemical Composition of Stainless Steel 310S Flange

A higher Carbon version, SS UNS S13009 Blind Flanges are excellent in such cases, they are resistant to carbide precipitation as well.

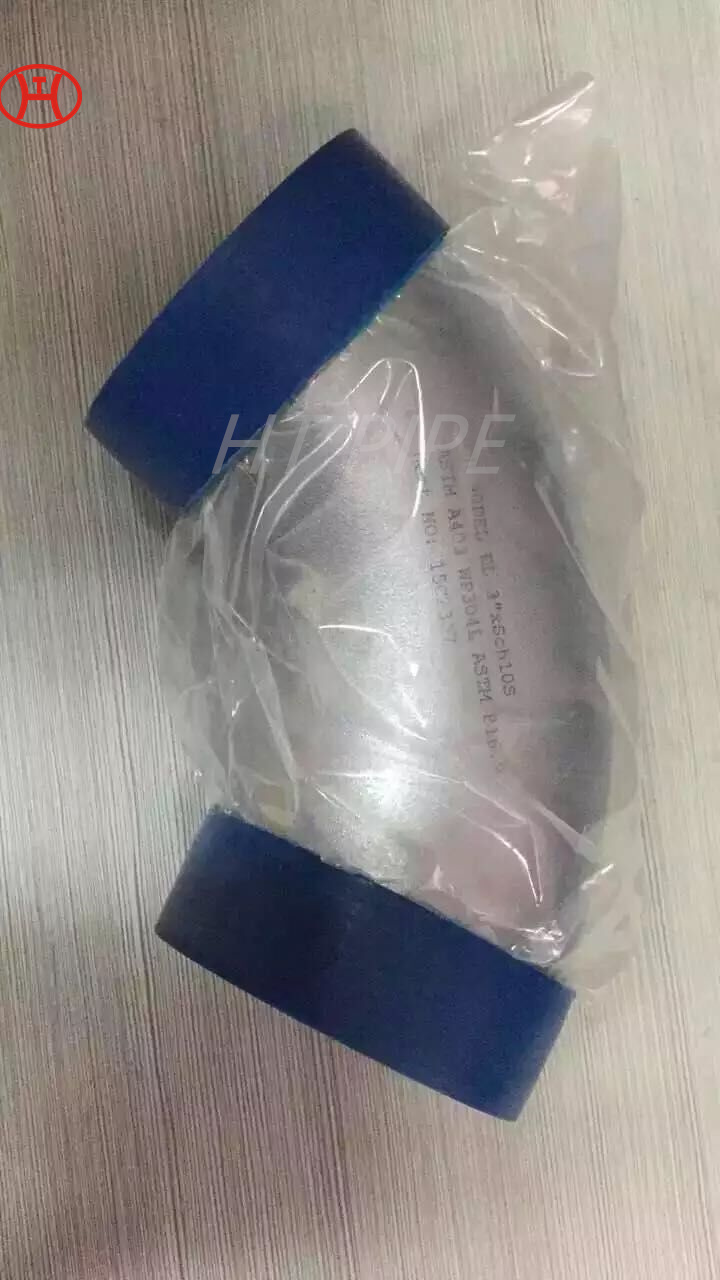

Stainless steel 310S threaded flanges has the best oxidation resistance to 2000F. One of the main features of stainless steel 310S slip-on flanges is that it provides moderate strength when the temperature is high. Our experts monitor each step and guide our workers to bring out the best quality products. We are providing SS 310/310S Flanges that can withstand easily in harsh and corrosive conditions. Alloy 310 can be utilized in slightly oxidizing, nitriding, cementing and thermal cycling applications, albeit, the maximum service temperature must be reduced. Alloy 310 also finds usage in cryogenic applications with low magnetic permeability and toughness down to -450oF (-268oC). When heated between 1202 ¨C 1742oF (650 ¨C 950oC) the alloy is subject to sigma phase precipitation. A solution annealing treatment at 2012 ¨C 2102oF (1100 ¨C 1150oC) will restore a degree of toughness.