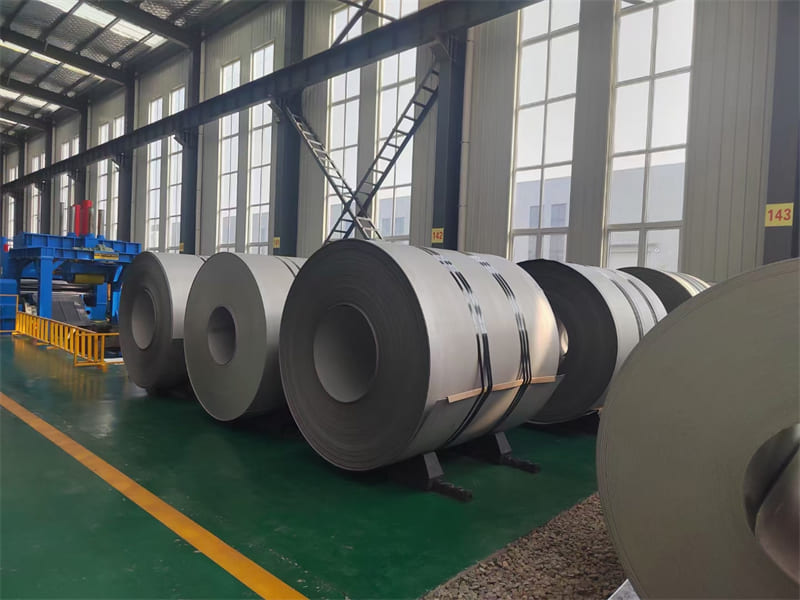

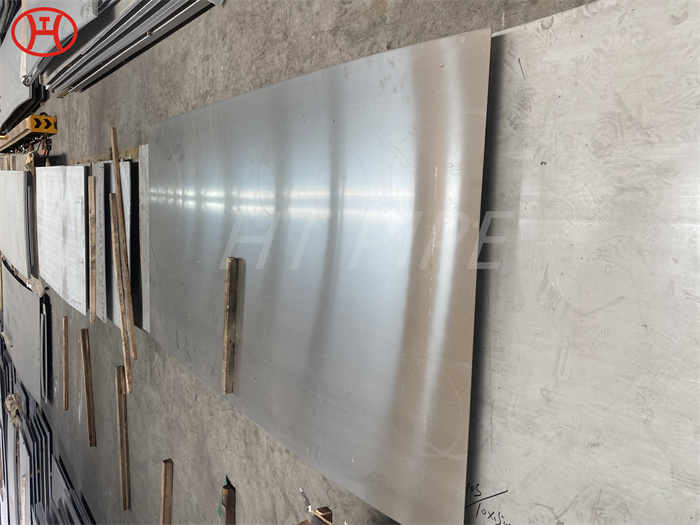

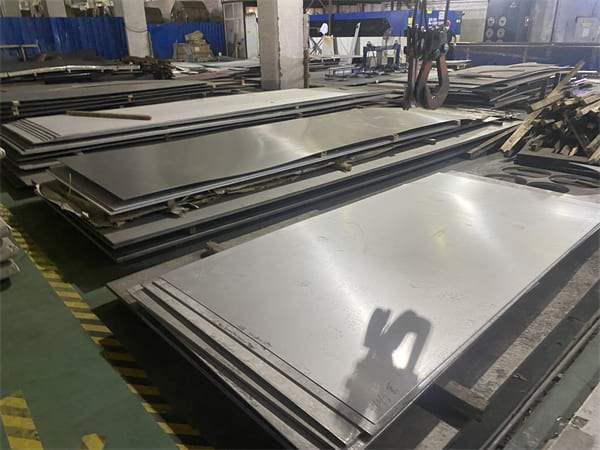

ASTM A240 Super Duplex 2507 Plates UNS S32750 Super Duplex Steel 2507 Hot Rolled Coils

2507 super duplex plate refers to a type of stainless steel plate that is made from a super duplex alloy with the designation UNS S32750. The Super Duplex 2507 is known for its high strength, excellent corrosion resistance, and good weldability, making UNS S32750 Sheet a popular choice for applications in the oil and gas, chemical processing, and marine industries.

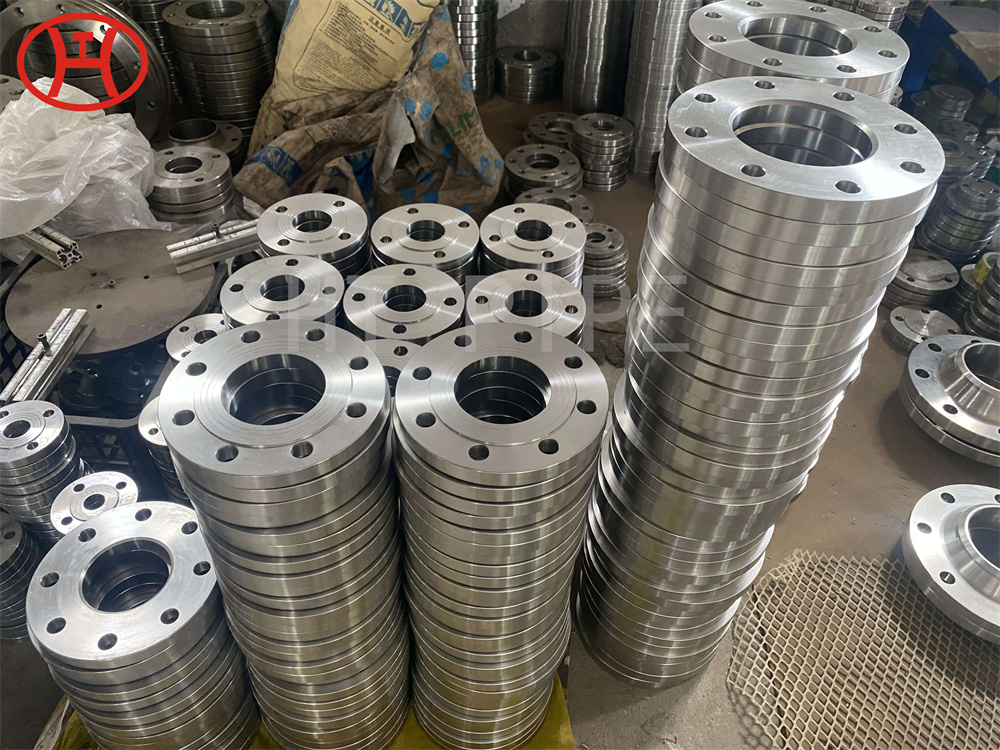

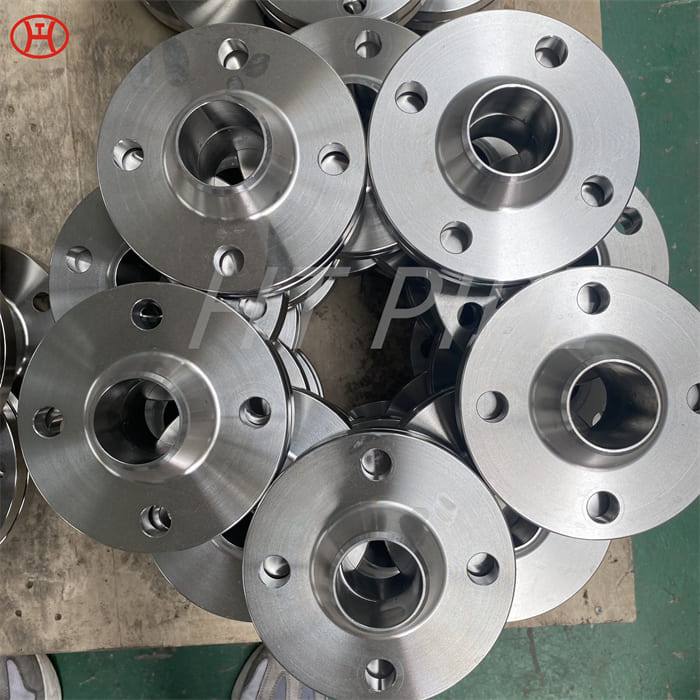

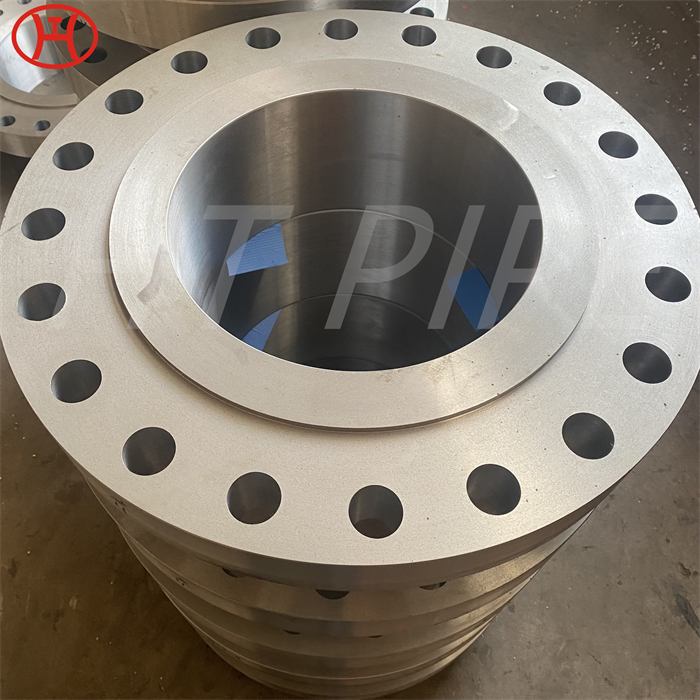

ASTM A240 Super Duplex 2507 Sheets, UNS S32750 Plates, Super Duplex Steel 2507 Hot Rolled Sheets, Super Duplex 2507 Plates, Super Duplex 2507 Cold Rolled Plates, Super Duplex UNS S32750 Perforated Sheets Manufacturer & Supplier in China.

2507 super duplex plate refers to a type of stainless steel plate that is made from a super duplex alloy with the designation UNS S32750. The Super Duplex 2507 is known for its high strength, excellent corrosion resistance, and good weldability, making UNS S32750 Sheet a popular choice for applications in the oil and gas, chemical processing, and marine industries.

This ASTM A240 Super Duplex 2507 possesses both high tensile and impact strength and is extremely corrosion resistant due to its chromium, molybdenum, and nitrogen content. We can provide our customers with array of stock shapes; round, square, hex, and we provide the industry’s best long stock, in lengths up to 28’.

Super Duplex Steel UNS S32750 Plate is highly resistant to chloride pitting, and stress, crevice, and general corrosion. Super Duplex Steel 2507 Hot Rolled Sheet can stand up well to organic and inorganic acids alike. All these resilient attributes make Super Duplex 2507 Plate extremely useful in harsh environments and Super Duplex 2507 Cold Rolled Plate is commonly used in chemical and petrochemical works, paper making facilities, and in marine contexts. HT PIPE, as UNS S32750 Plate super duplex manufacturer, can furnish our customers with super duplex UNS S32750 sheet at any marine project.

Super Duplex 2507 Plate has high thermal conductivity and a low rate of thermal expansion, allowing for use in heat exchangers and water heaters, though long-term exposure to temperatures near or exceeding 600°F will lead to a decrease in strength.

Lastly, S32750 Plate is stronger than more nickel-based alloys, allowing for less material to do similar jobs, saving on cost and weight. Super Duplex UNS S32750 Sheet is also more workable and weldable than pure austenitic alloys.

The “2507” in the name refers to the nominal composition of the alloy, which contains approximately 25% chromium, 7% nickel, 4% molybdenum, and small amounts of other elements such as nitrogen and copper. The term “super duplex” indicates that the material has a dual-phase microstructure consisting of both austenite and ferrite phases, which contributes to the superior mechanical and corrosion properties of ASME SB 240 Super Duplex Werkstoff Nr. 1.4410 Plate.

S32750 Plate is available in a range of thicknesses, widths, and lengths, and can be supplied in either a hot-rolled or cold-rolled condition. S32750 Hot Rolled Plate is typically used in applications that require high strength, resistance to corrosion and erosion, and good toughness, such as pressure vessels, piping systems, heat exchangers, and structural components.

Super Duplex 2507 / UNS S32750 Sheets & Plates Chemical Composition

| Grade | S32750 |

| C | 0.030 max |

| Mn | 1.20 max |

| Si | 0.80 max |

| P | 0.035 max |

| S | 0.020 max |

| Cr | 24.00 – 26.00 |

| Mo | 3.00 – 5.00 |

| Ni | 6.00 – 8.00 |

| N | 0.24 – 0.32 |

| Fe | 58.095 min |

Mechanical Characteristics of Super Duplex 2507 Plate

| Ultimate Tensile Strength, ksi | 116 minimum |

| Yield Strength 0.2%, ksi | 80 minimum |

| Yield Strength, ksi | 91 minimum |

| Elongation in % | 15 minimum |

| Hardness | 32 maximum |

| Impact Energy | 74 minimum |