ASTM A269 Alloy 254 Seamless Pipe Material Manufacturers

ASTM A269 Alloy 254 Seamless Pipe Material is a very high end austenitic stainless steel.

ASTM A269 Alloy 254 Seamless Pipe Material Manufacturers in China, Wide Stockist of ASME SA312 SMO 254 Pipe

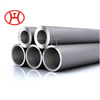

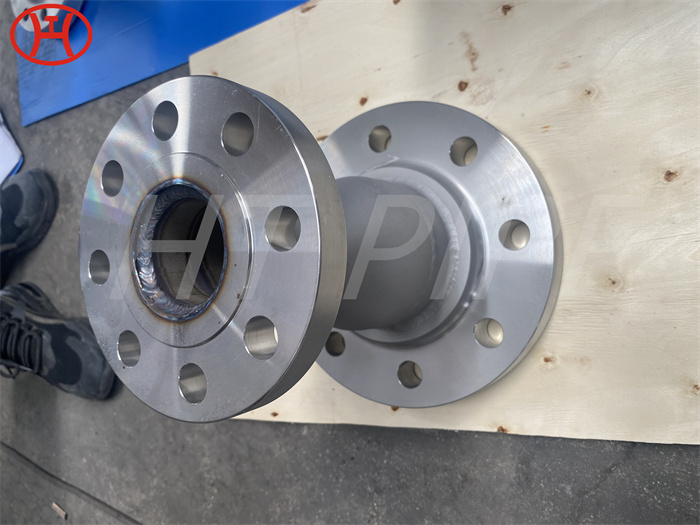

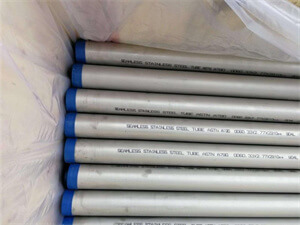

254 SMO Seamless Pipe is designated as UNS S31254 and Werkstoff Number 1.4547. 254 SMO Seamless pipe standard is ASTM A269, A213, A312, NFA 49-217, EN 10216-5 and 254 SMO Stainless Steel Pipe: ASTM A249, A269. With high levels of chromium, molybdenum, and nitrogen, 254SMO is especially suited for high-chloride environments and offers chloride resistance superior to Alloy 904L, SS316L, Alloy 20 and Alloy 825. ASME SA312 SMO 254 Pipe can be readily welded to other common austenitic stainless steels. The 254 SMO stainless steel pipe provides outstanding resistance to pitting corrosion, crevice corrosion, as well as stress-corrosion cracking. These Alloy 254 pipes are usually seamless and pressure rated to avoid leakages as they usually carry liquids or gases. Alloy 254 Seamless Pipe ends are available with plain or beveled form.

UNS S31254 or DIN W.Nr. 1.4547, 254SMO is an Cr-Ni-Mo alloyed super austenitic stainless steel with deliberate additions of copper and nitrogen content. The delivery condition of 254 SMO Stainless Steel Pipe is either solution annealed and white pickled, or solution annealed in a bright annealing process. Alloy 254 Thin Wall Pipe, 254 SMO High Alloy Stainless Steel Pipes, Alloy 254 SMO Stainless Steel Seamless Pipes typically finds ASTM A312 Alloy 254 Polished Pipes applications including Marine, Chemical processing, Pollution control equipment, industries, Nuclear reactors, etc.

CHEMICAL COMPOSITION OF SMO 254 PIPE TUBE

| Grade | C | Mn | Si | S | Cu | Ni | Cr | N | Mo | P |

| SMO 254 | 0.02 max | 1 max | 0.8 max | 0.01 max | 0.5 – 1 | 17.5 – 18.5 | 19.5 – 20.5 | 0.18 – 0.22 | 6 – 6.5 | 0.03 max |

MECHANICAL PROPERTIES OF SMO 254 PIPE TUBE

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1320-1390°C | 650 | 300 | 35% |