ASTM A276 309 UNS S30900 Stainless Steel Rods

ASTM A276 309 UNS S30900 Stainless Steel Rods are high-temperature and corrosion-resistant materials widely used in demanding environments. They are crafted from a chromium-nickel alloy and are particularly known for their excellent oxidation resistance and strength at elevated temperatures.

ASTM A276 309 UNS S30900 Stainless Steel Rods, ASTM A276 309 Stainless Steel Bars, Stainless Steel 309 Rods, Stainless Steel UNS S30900 Bars, Cold Rolled 309 Stainless Steel Flat Bar, 309 Stainless Steel Bars.

ASTM A276 309 UNS S30900 Stainless Steel Rods are high-temperature and corrosion-resistant materials widely used in demanding environments. They are crafted from a chromium-nickel alloy and are particularly known for their excellent oxidation resistance and strength at elevated temperatures.

- ASTM A276 309 Stainless Steel Bars Features

Outstanding oxidation resistance up to 1000°C.

Suitable for both aqueous and high-temperature environments.

Good weldability and formability.

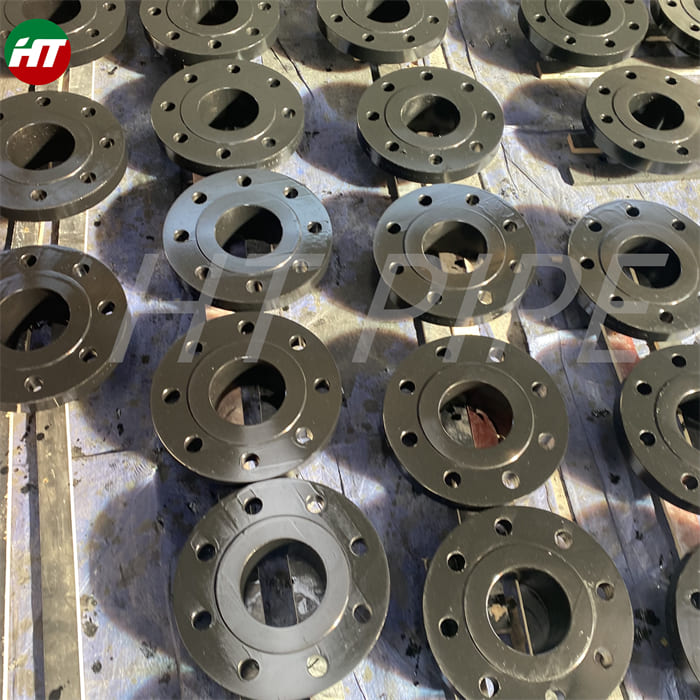

- Stainless Steel 309 Rods Applications:

Heat exchangers

Furnace parts

Chemical processing equipment

Kilns and incinerators

Food processing industries

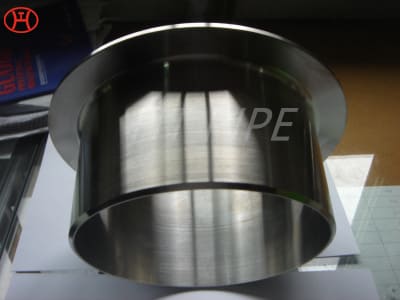

- Stainless Steel UNS S30900 Bars Available Forms:

These rods are available in various sizes, diameters, and finishes such as polished, black, or bright bars, depending on your project requirements.

- Cold Rolled 309 Flat Bar Corrosion Resistance:

Exceptional resistance to oxidation at high temperatures (up to 1000°C).

Good performance in mildly corrosive environments.

Susceptible to stress corrosion cracking in chloride-rich environments; choose duplex or specialized alloys if needed.

- 309 Stainless Steel Bar Workability:

Can be hot-worked at temperatures between 1177°C and 982°C.

Cold working improves strength and hardness but slightly reduces ductility.

Easily welded using standard methods like TIG, MIG, or resistance welding.

- 309 vs. 310:

Grade 310 has higher chromium and nickel content, providing superior heat resistance.

309 is more economical while still maintaining robust performance at high temperatures.

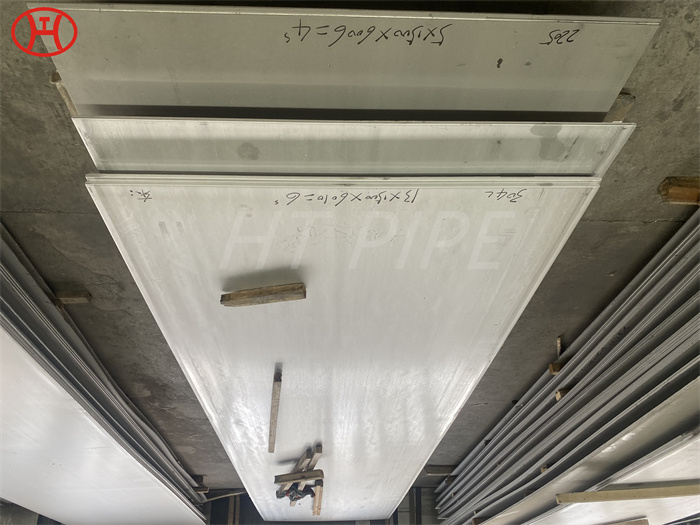

- ASTM A276 309 Bar Available Sizes and Standards

Standard Dimensions:

Diameter: 3mm to 400mm (or customized)

Length: Fixed (1m, 3m, 6m) or random cut to your needs.

Tolerances: Complies with ASTM A276 dimensional standards.

- UNS S30900 Bar Surface Finishes:

Hot Rolled (HR): Ideal for applications needing toughness without surface precision.

Cold Drawn (CD): For precise applications requiring smooth surface finishes.

Polished or Bright Bars: Aesthetic applications or environments needing extra cleanliness.

- Advantages of Using ASTM A276 309 Rods

Withstands extreme thermal cycling without warping or cracking.

Long-term resistance to scaling and oxidation in continuous or intermittent service.

Excellent performance in reducing and carburizing atmospheres.

- Quality Assurance

Supplied as per strict ASTM standards with mill test certificates (MTC).

Non-destructive testing (NDT), including ultrasonic or eddy current, ensures defect-free products.

SS 309 Round Bar Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 309 | 0.10 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 10.5 | – |

SS 309 Round Bar Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 309/309L | 515 | 205 | 40% | 85 | 147 |