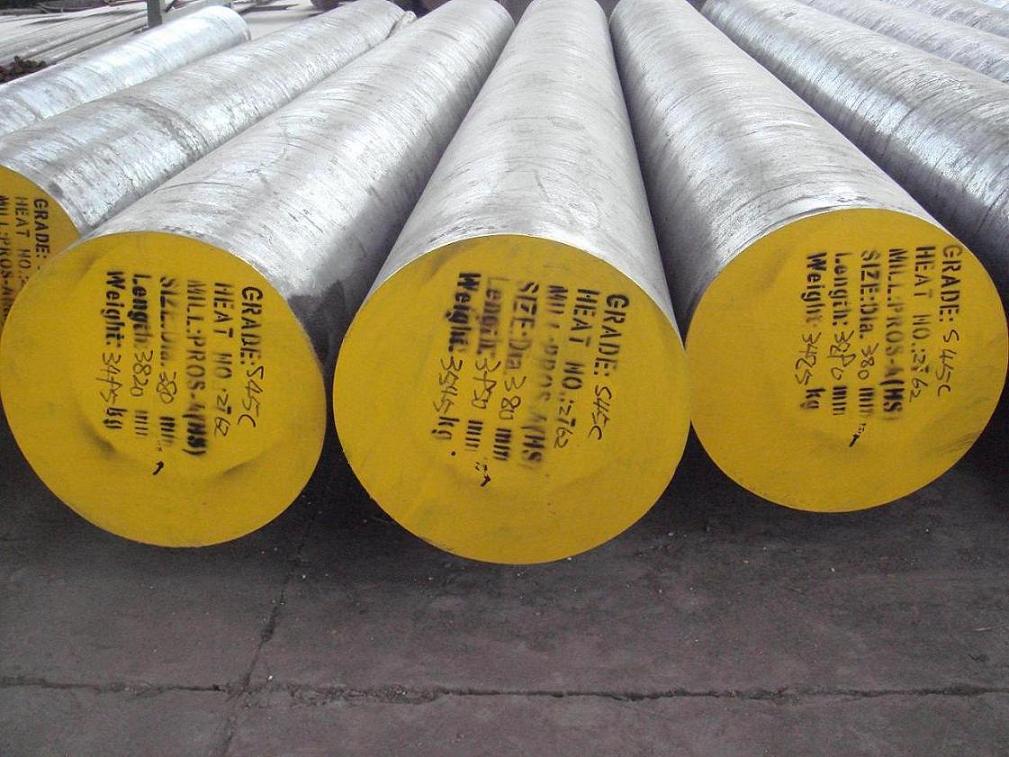

Astm A276 321 Rod 18Mm Bright 316 Stainless Square Steel Bar Diameter 16Mm

321 Stainless Steel Square Bar It can be categorically said that rebar is one of the core components of any manufacturing industry or any industry that relies on machinery. Widely used in automotive, textile, manufacturing, construction, cement, shipbuilding, paper and pulp, defense, heavy earthmoving equipment or aerospace.

ASTM A276/ ASME SA 276 UNS S32100 Rod Manufacturer And Supplier

Grade 321 stainless steel belongs to the austenitic class 300 series. Like most of the 300 series stainless steel alloys, the JIS SUS 321 black bar has multiple mechanical and corrosion resistance properties. The chemistry of UNS S32100 Bar is similar to grade 304, with the only difference that alloy 321 stainless steel round bar has been stabilized with the addition of titanium in its alloy. Adding titanium in any alloy is beneficial, particularly if UNS S32100 Bar has to undergo welding operations. During welding, the titanium forms titanium carbides on the weld seam, which is comparatively stable as opposed to carbide precipitation.

Hence, alloy 321 stainless steel rods have superior resistance to intergranular corrosion and their grain boundary does not undergo sensitization. The inclusion of titanium also improves the mechanical properties of the astm a276 type 321 flat bar, when subjected to extremely high temperatures. The yield strength and impact resistance of the alloy remains the same. Another common ground between grade 304 and the ASTM A479 UNS S32100 hex bar is that they deliver excellent performance even in cryogenic environments. Alloys that are a part of cryogenic applications need to have a good impact strength and good mechanical properties, with the alloying of metals like chromium and nickel, the smaller amounts of manganese and titanium ensure that the DIN 1.4541 square bar used is up to the mark. Yet, the main reasons buyers choose to use AISI 321 threaded bar for their applications is that the material has superior creep strength at high temperatures. When alloys like 304 are susceptible to failing at such temperatures, grade ss 321 bright bar is able to thrive and have a lasting performance.

| Grade | Ti | Mn | C | Si | S | P | Mo | Cr | Ni |

| SS 321 | 5(C+N) to 0.70 maximum | 2.0 maximum | 0.08 maximum | 1.0 maximum | 0.030 maximum | 0.045 maximum | – | 17.00 to 19.00 | 9.00 to 12.00 |

| Melting Point | Density | (0.2%Offset) Yield Strength | Tensile Strength | Elongation |

| 1457 °C (2650 °F) | 8.0 g/cm3 | Psi – 30000 , MPa – 205 | Psi – 75000 , MPa – 515 | 35 % |