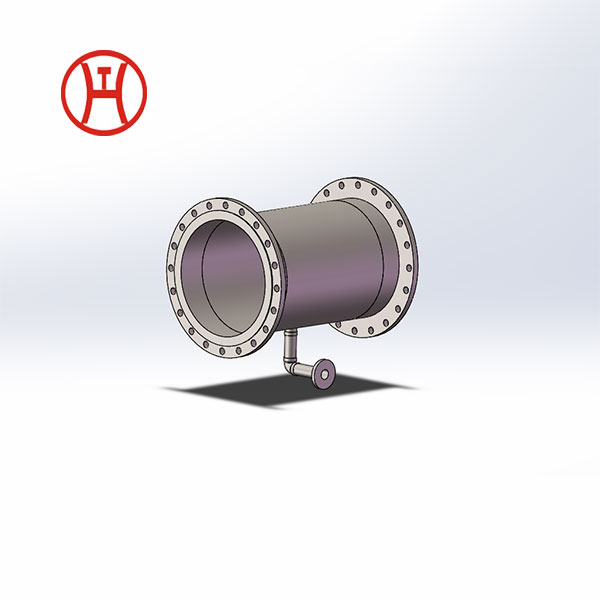

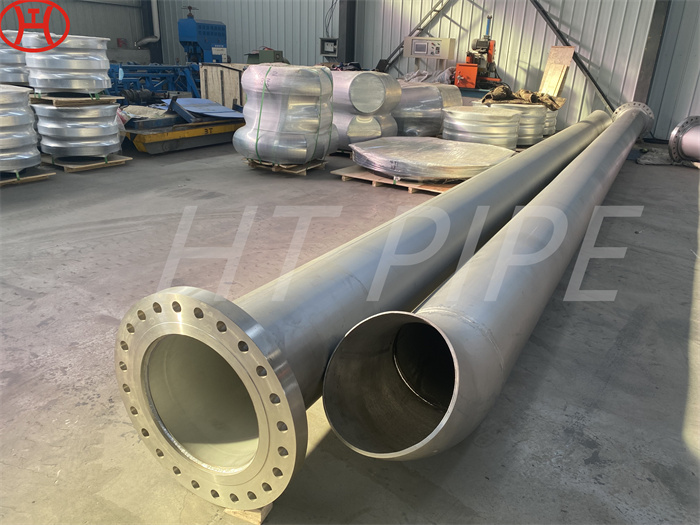

ASTM A312 254 SMO Stainless Steel Seamless Pipe with Flange

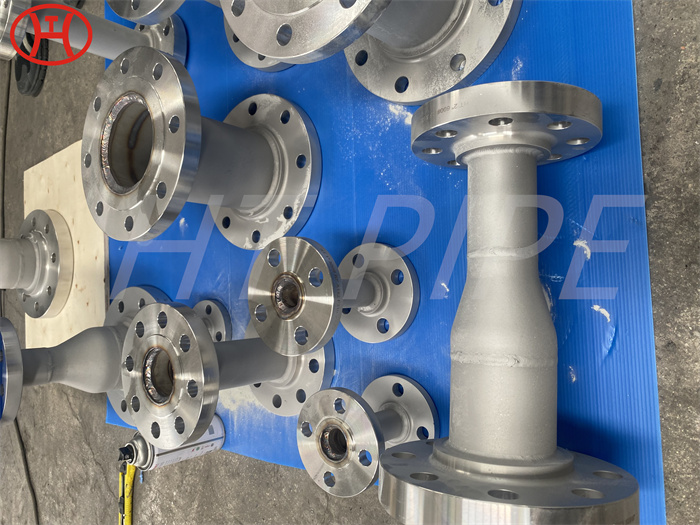

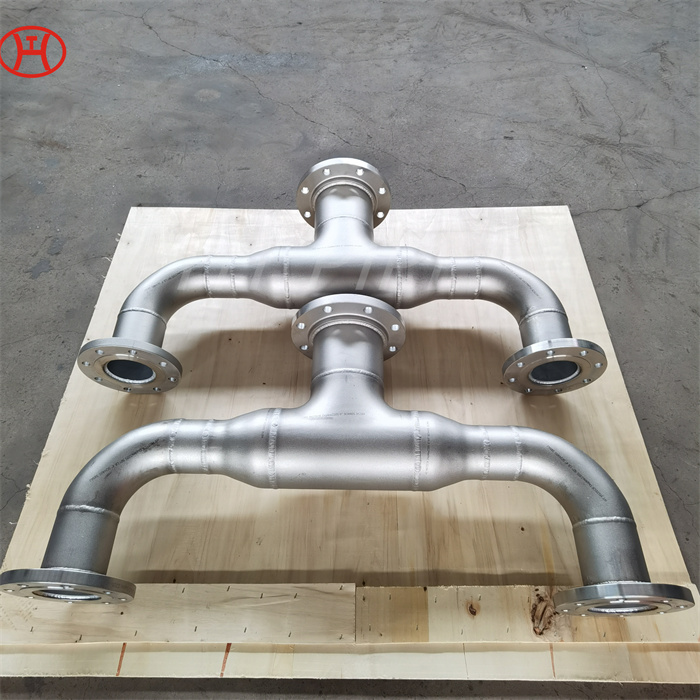

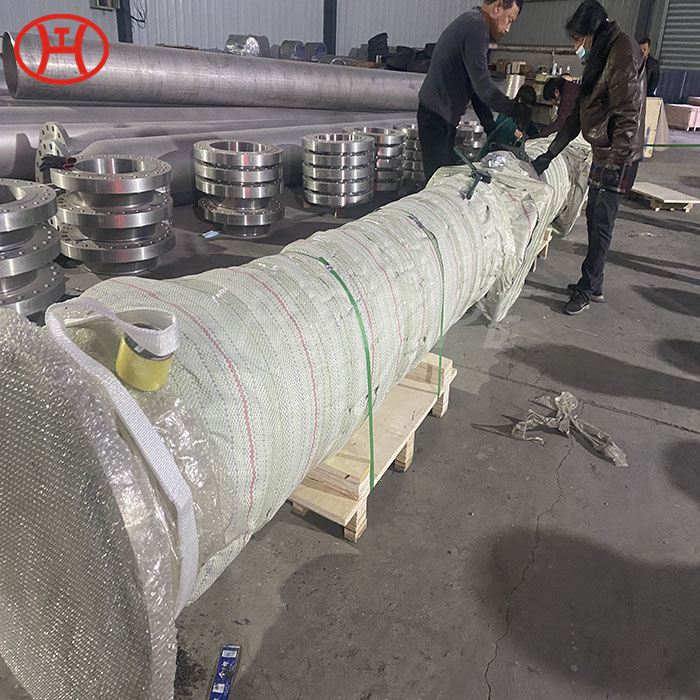

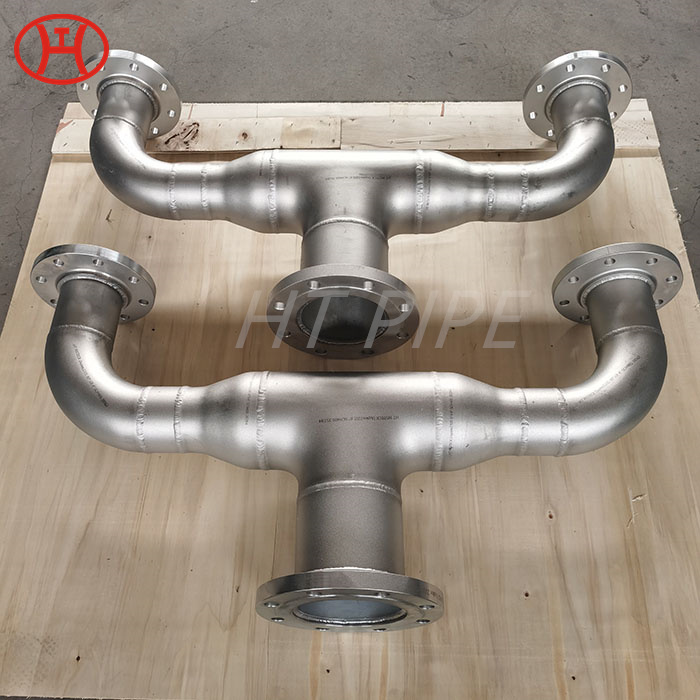

Customized Prefabrication Pipe Spools

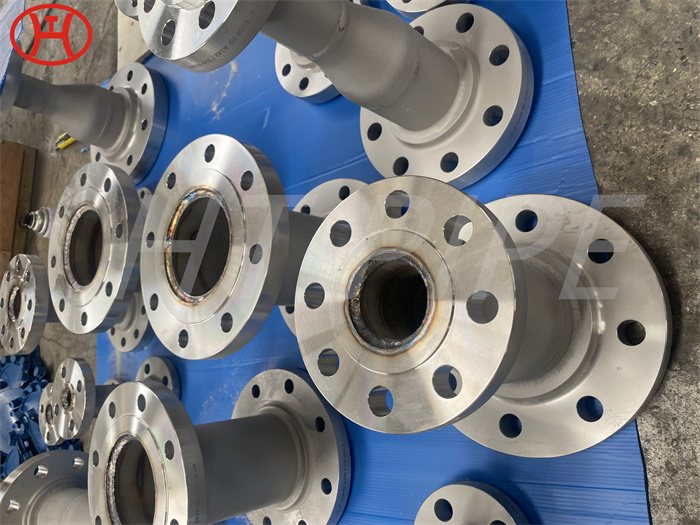

Pipe welded with Flanges

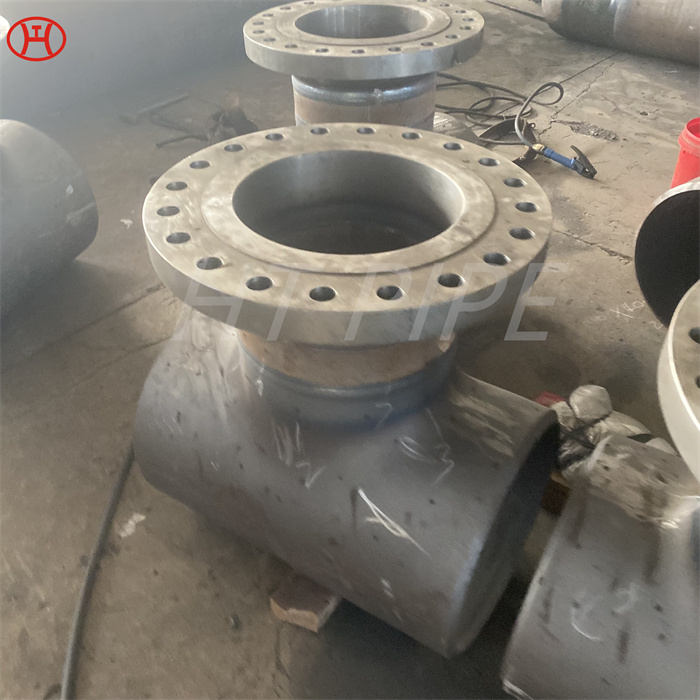

Pipe welded with Fittings

Flanges welded with Fittings

ASTM A312 254 SMO Stainless Steel Seamless Pipe with Flange,SS 254 SMO Seamless Pipe,UNS S31254 Seamless Pipe,ASTM A312 254 SMO Pipe,ASME SA312 UNS S31254 Pipe,DIN 1.4547 Seamless Pipe,F44 Pipe,254 SMO Pipe with Flange, 254 SMO Seamless Pipe Price,UNS S31254 Seamless Pipe Manufacturer, SMO 254 Seamless Pipe Supplier,Pipe Spools Fabrication,Pre-Fabrication Pipe Spools

What is ASTM A312 254 SMO stainless steel seamless pipe with flange? 254 SMO stainless steel pipe is a super austenitic stainless steel pipe with high molybdenum content. 254 SMO flanges are usually used to connect pipelines, valves or other equipment, and can be welded, screwed or bolted to pipelines. Alloy F44 has impact toughness resistance to chloride stress corrosion cracking, pitting and crevice corrosion. 254 SMO pipe with flange belongs to the direct welding of the flange on the pipeline, which is convenient for the coordination and control of quality, progress and management. Reduce the workload of on-site prefabrication and on-site installation, save installation time and labor costs, and greatly improve the installation, quality, and progress of the entire project.

ASTM A312 254 SMO stainless steel seamless pipe with flange is made of 254 SMO stainless steel pipe with flanges attached at one or both ends to the specifications outlined in the ASTM A312 standard. SS 254 SMO seamless pipe not only has high nickel and chromium content, but also contains 6% Mo element, also known as 6Mo pipe, ASTM A312 254 SMO pipe is resistant to pitting and crevice corrosion, and also has strong resistance to chloride stress corrosion cracking. In some applications, ASME SA312 UNS S31254 pipe is a more cost-effective alternative to high nickel and titanium alloys.

F44 pipe contains high content of chromium, molybdenum and nitrogen, and its strength is twice that of ordinary 300 series stainless steel. And UNS S31254 seamless pipe is made of a whole piece of metal with no seams on the surface. The welded pipe is a steel pipe made of steel plate or strip steel after being crimped and welded. The bearing strength of the seamless pipe is greater than that of the welded pipe. 254 SMO pipe with flange is widely used in seawater, oil production, brine treatment, pulp bleaching and food processing industries.

HT PIPE is a supplier and exporter of SMO 254 seamless pipe. It provides DIN 1.4547 seamless pipe and ATSM A182 flange in accordance with ATSM A312 standard, and provides prefabricated welding products of ASTM A312 254 SMO stainless steel seamless pipe with flange. Welcome to consult.

Chemical Composition of 254 SMO stainless steel pipe

| Element | SMO 254 |

| C | 0.02 max |

| Mn | 1 max |

| Si | 0.8 max |

| S | 0.01 max |

| Cu | 0.5 – 1 |

| Ni | 17.5 – 18.5 |

| Cr | 19.5 – 20.5 |

| N | 0.18 – 0.22 |

| Mo | 6 – 6.5 |

| P | 0.03 max |

Mechanical Properties 254 SMO stainless steel seamless pipe

| Element | SMO 254 |

| Density | 8.0 g/cm3 |

| Melting Point | 1320-1390°C |

| Tensile Strength | 650 |

| Yield Strength | 300 |

| Elongation | 35% |

| Hardness (HB) max | 220 |

ASTM A312 254 SMO stainless steel seamless pipe specification

| Pipe Specifications | ASTM A312 / ASME SA 312 |

| Pipe Standard | DIN, JIS, ASTM, EN, GB, AISI, ASME |

| Pipe Thickness | 0.3mm – 50 mm |

| Seamless Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe & Tube End | Plain End, Beveled End, Treaded Pipe. |