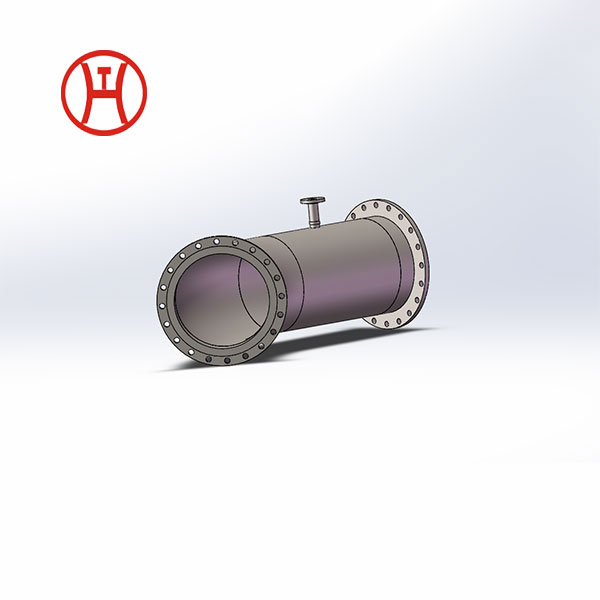

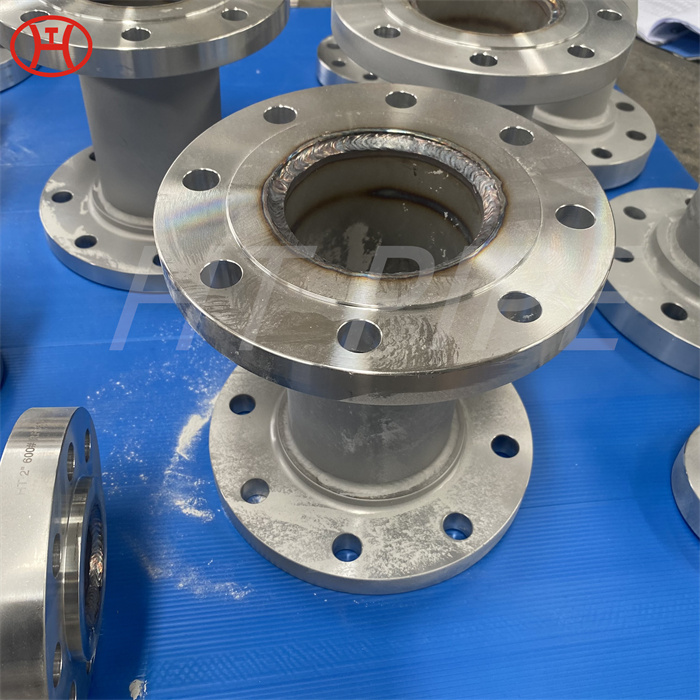

ASTM A312 TP904L Stainless Steel Seamless Pipe with Flange

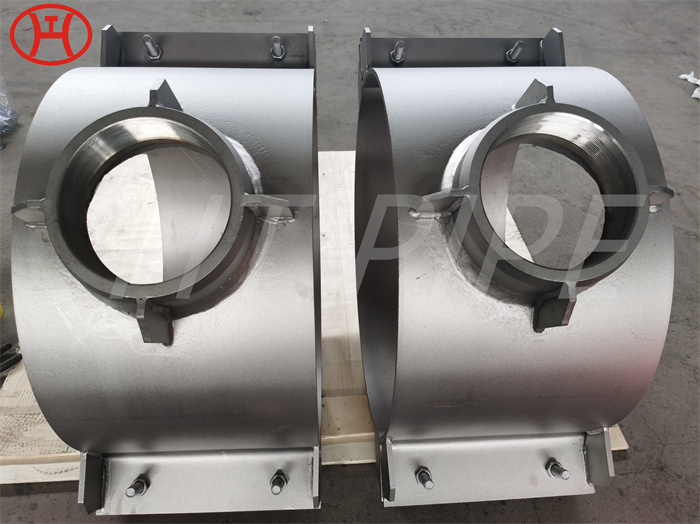

Customized Prefabrication Pipe Spools

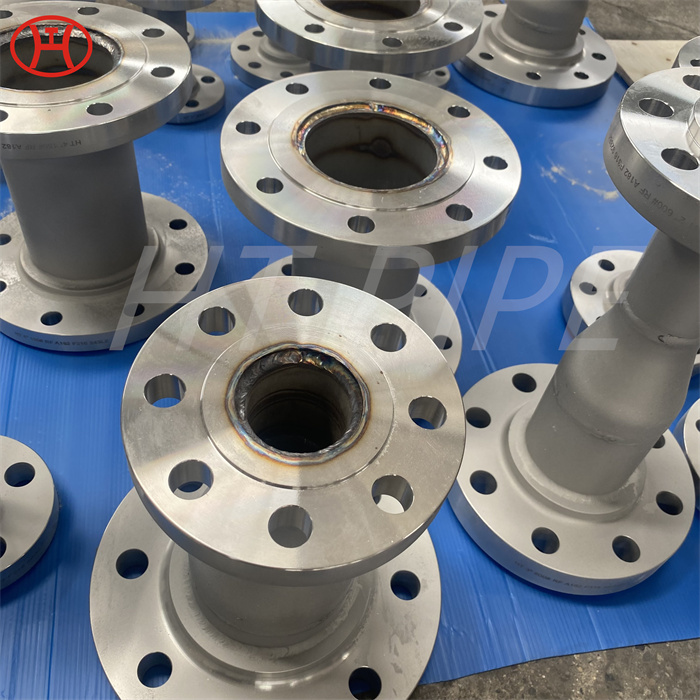

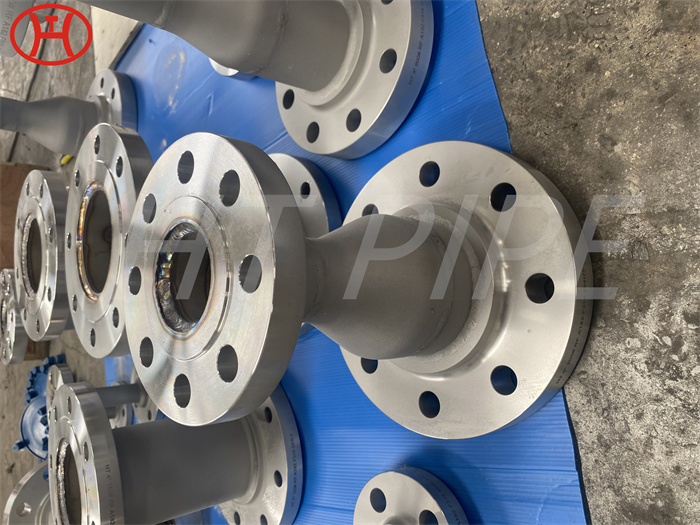

Pipe welded with Flanges

Pipe welded with Fittings

Flanges welded with Fittings

ASTM A312 TP316L Stainless Steel Seamless Pipe with Flange,ASTM A312 TP904L Stainless Steel Seamless Pipe,UNS N08904 Seamless Pipe,ASME SA312 904L Stainless Steel Pipe,DIN 1.4539 Pipe,904L Pipe with Flange, 904L Seamless Pipe Price,904L Seamless Pipe Manufacturer,SS 904L Seamless Pipe Supplier,Pipe Spools Fabrication,Pre-Fabrication Pipe Spools

904L stainless steel composition contains 23% nickel, 19% chromium, carbon, manganese, silicon, phosphorus, sulfur and 4% molybdenum, and 1.0%-2.0% copper. UNS N08904 seamless pipe obtains corrosion resistance and strength from the composition. The material has a yield strength of 220MPa and a tensile strength of 490MPa. The seamless pipe has a stronger pressure bearing capacity than the welded pipe, and it also has a Rockwell B hardness value of 70-90 . 904L stainless steel is a high performance austenitic stainless steel, ASTM A312 TP904l stainless steel seamless pipe with flange is popular for its excellent corrosion resistance and ability to withstand harsh environments, often used in chemical processing, pharmaceutical, oil and gas industries .

TP904L is a low carbon, high alloy austenitic stainless steel with excellent corrosion resistance, especially in sulfuric acid and chloride environments. Due to the high molybdenum content of this alloy 904L, SS 904L seamless pipe has excellent resistance to localized attack, especially in forms of corrosion such as pitting and crevice corrosion. Furthermore, DIN 1.4539 pipe has very good resistance to reducing acids and the addition of copper gives ASTM A312 904L pipe general corrosion resistance to sulfuric acid of various concentrations.

Prefabricated welding ASTM A312 TP904l stainless steel seamless pipe with flange, the flange is usually specified separately from the pipeline specification, and the flange needs to be selected according to the expected application and design requirements. Flanges are usually bolted to pipes, and the connection between flanges and pipes is sealed with gaskets. It is important to work with a reputable supplier to ensure that 904L pipe with flange meets the required specifications and is manufactured to the highest quality standards.

HT pipe is a 904L seamless pipe supplier that will manufacture these spools. Our workshops and fabrication facilities are staffed by skilled craftsmen, pipe fitters, pipe fabricators, pipe welders and are delivered pre-assembled for easier assembly using cranes, gauges and other assembly tools. Use prefabricated welding ASTM A312 TP904l stainless steel seamless pipe with flange to improve product quality and production efficiency, and ultimately save a lot of cost for customers.

Chemical Composition of 904L pipe

| Element | SS 904L |

| C | 0.020 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.040 max |

| S | 0.030 max |

| Cr | 19.00 – 23.00 |

| Mo | 4.00 – 5.00 max |

| Ni | 23.00 – 28.00 |

| Cu | 1.00 – 2.00 |

Mechanical Properties ASTM A312 904L ss seamless pipe

| Element | SS 904L |

| Density | 7.95 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 71000 , MPa – 490 |

| Yield Strength (0.2%Offset) | Psi – 32000 , MPa – 220 |

| Elongation | 35% |

ASTM A312 904L stainless steel seamless pipe specification

| Pipe Specifications | ASTM A312 / ASME SA 312 |

| Pipe Standard | DIN, JIS, ASTM, EN, GB, AISI, ASME |

| Pipe Thickness | 0.3mm – 50 mm |

| Seamless Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe & Tube End | Plain End, Beveled End, Treaded Pipe. |