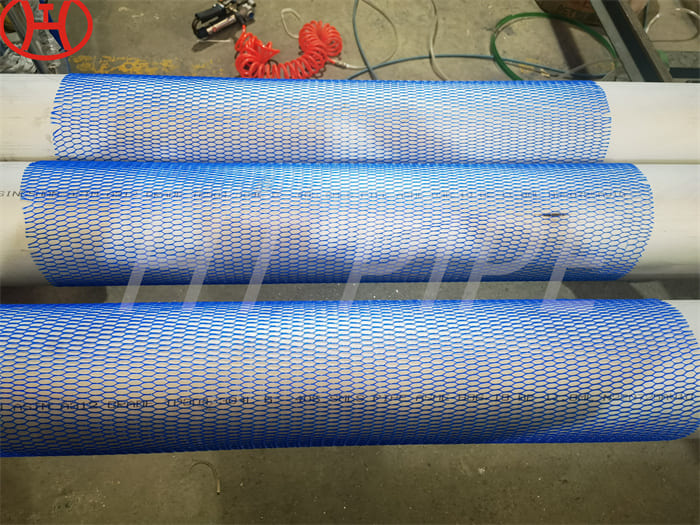

ASTM A312 UNS S31254 Welded and ERW Tube manufacturer in China

SMO 254 Hexagonal Pipes is subject to pitting and crevice corrosion in warm chloride environments and to stress corrosion cracking above about 60 Degree C.

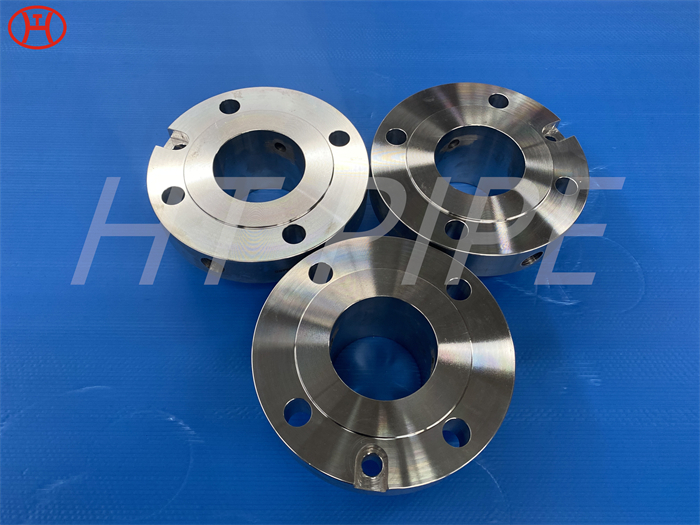

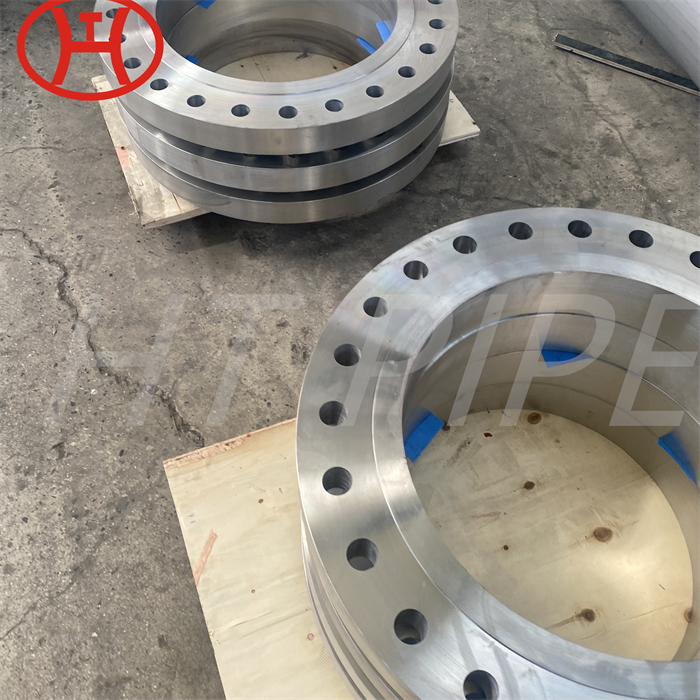

254 SMO Seamless Pipe, SMO 254 Seamless Pipe, SMO 254 Welded Pipes, SMO 254 ERW Pipes, SMO 254 Hollow Pipe, SMO 254 EFW Pipes, SMO DIN NR. 1.4547 Pipes, ASME SB403 Welded SMO Pipes, SMO 254 Pipes, 254 SMO Welded Pipe Manufacturer in China.

SMO 254 Square Pipes are also being offered in different sizes and shapes to our customers. Ganpat Industrial Corporation is one of the well-known supplier and stockist of SMO 254 Rectangular Pipes, which is also known as 18 / 8 stainless steel and is the most common stainless steel. SMO 254 Electropolish Pipes has excellent resistance to a wide range of atmospheric environments and many corrosive media. Under some circumstances, the UNS S31254 SMO Seamless Pipe is considered to be a highly economical, yet commercially viable solution to applications that are prone to corrosion.

In fact, the corrosion resistance properties of 250 SMO pipe is compared to nickel alloys. One of the most remarkable qualities of this 254 smo en 1.4547 pipe is its resistance to marine environments, and in particular, elevated temperature seawater. The level of salt in seas across the world varies, depending on several parameters. The normal rate of salt or sodium chloride present in seawater amounts to about 3.5%. In areas where the river forms a confluence with the sea, the concentration of sodium chloride in water reduces. When compared to standard stainless steel A213 Uns S31254 Seamless Tube has a high molybdenum content that increases the oxidation rate during annealing and results in a rougher surface finish after pickling. Alloy 254 High-Pressure Tubes are stronger than common austenitic grades and are easy to weld. Din 1.4547 Welded Tubes are considered to be a cost-effective substitute for the alloy with high nickel content and titanium. To attain maximum corrosion resistant properties Tubo Smo 254 requires post-processing annealing.

SMO UNS S31254 Seamless Pipe Chemical Composition

| Grade | C | Ni | Si | N | S | Mn | P | Cr | Ce | Fe | |

| SS 254 SMO | min. | – | 17.5 | – | 0.18 | – | – | – | 19.5 | 0.03 | Balance |

| max. | 0.02 | 18.5 | 0.08 | 0.22 | 0.01 | 1.00 | 0.03 | 20.5 | 0.08 | ||

SMO WERKSTOFF NR. 1.4547 Seamless Pipes Mechanical Properties

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS 254 SMO | 650 | 35 | 300 | 50 | 270 |