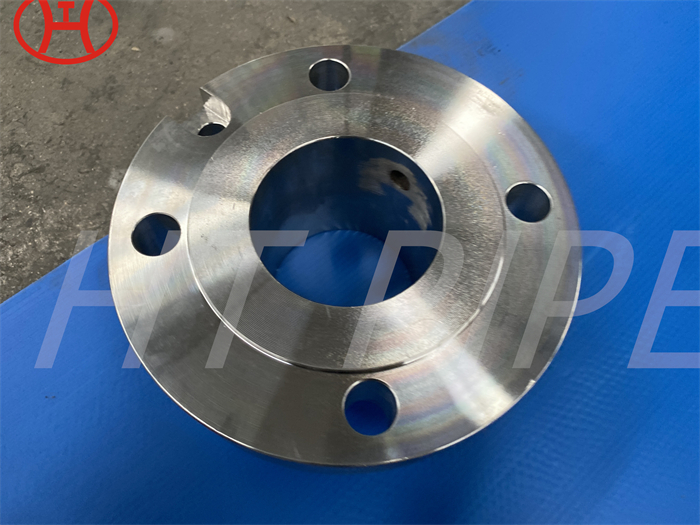

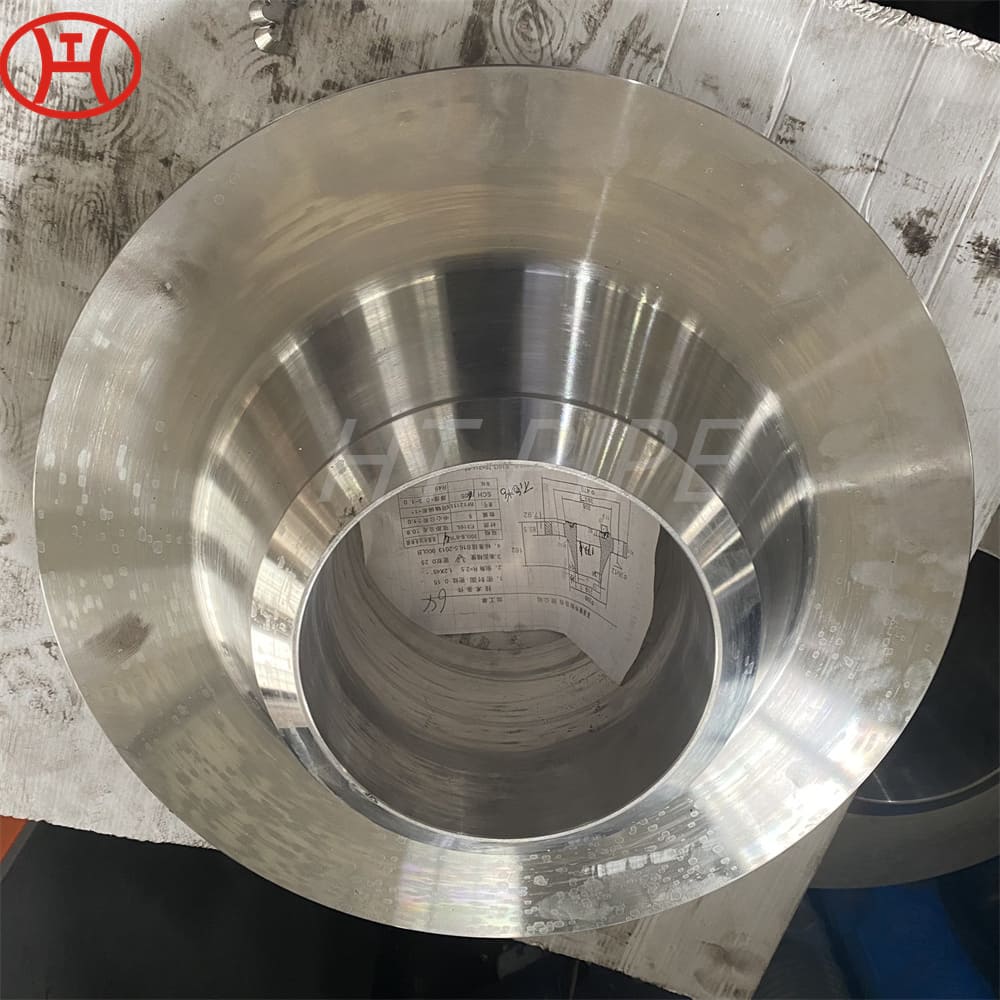

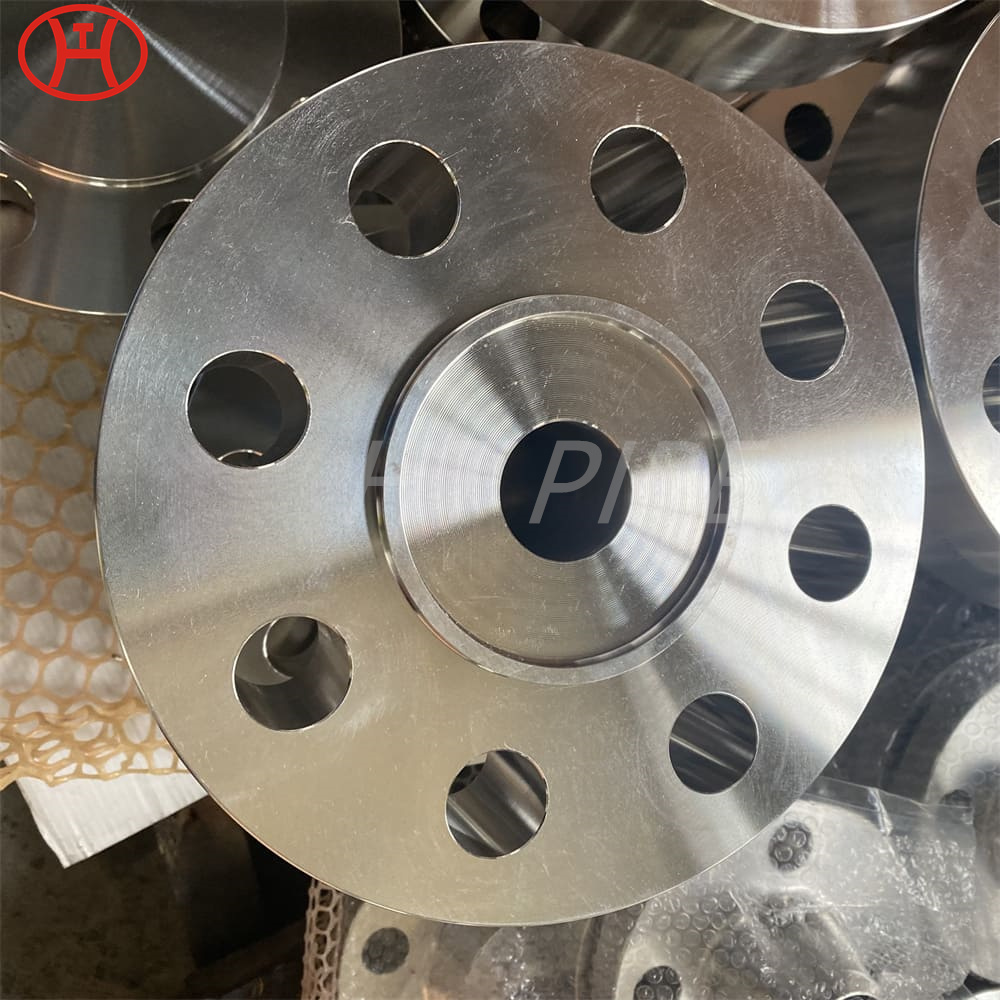

astm a335 p5 pipe of high quality

The key to the P5 composition of chromium-molybdenum alloys is the addition of chromium and molybdenum. Chromium or chromium increases high temperature strength, increases oxidation resistance and increases tensile, yield and hardness at room temperature. Molybdenum improves strength, elastic limit, wear resistance, impact quality and hardenability. It increases resistance to softening, inhibits grain growth, and makes chrome steel less susceptible to embrittlement. Molybdenum is also the most effective additive for increasing high temperature creep strength or creep resistance. It also enhances the corrosion resistance of the steel and inhibits pitting corrosion.

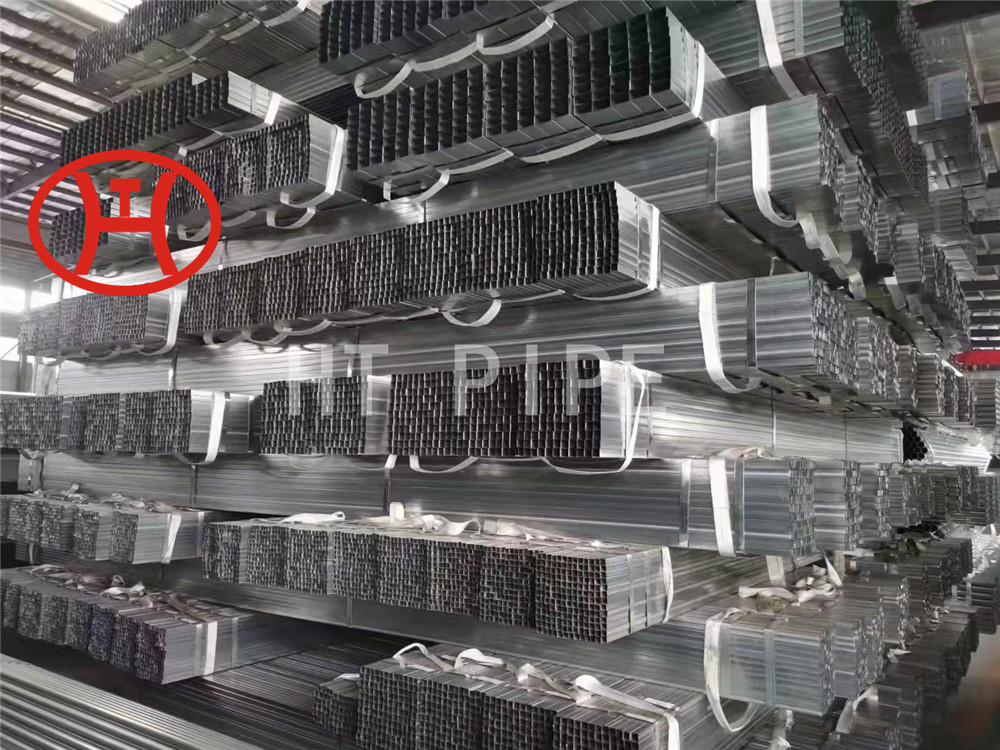

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Alloy Steel ASTM A333 Grade 3, Grade 6,Grade 8,Grade 9

ASTM A335 P5,P9,P11,P12,P22,P91,P107

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Alloy Steel ASTM A333 Grade 3, Grade 6,Grade 8,Grade 9

ASTM A335 P5,P9,P11,P12,P22,P91,P107