ASTM A335 P9 Seamless Steel Pipe Chrome Moly Pipe

The P2 and P12 steel pipes of A335 should be made by the coarse grain melting method. Steel should meet chemical composition, tensile properties and hardness requirements.

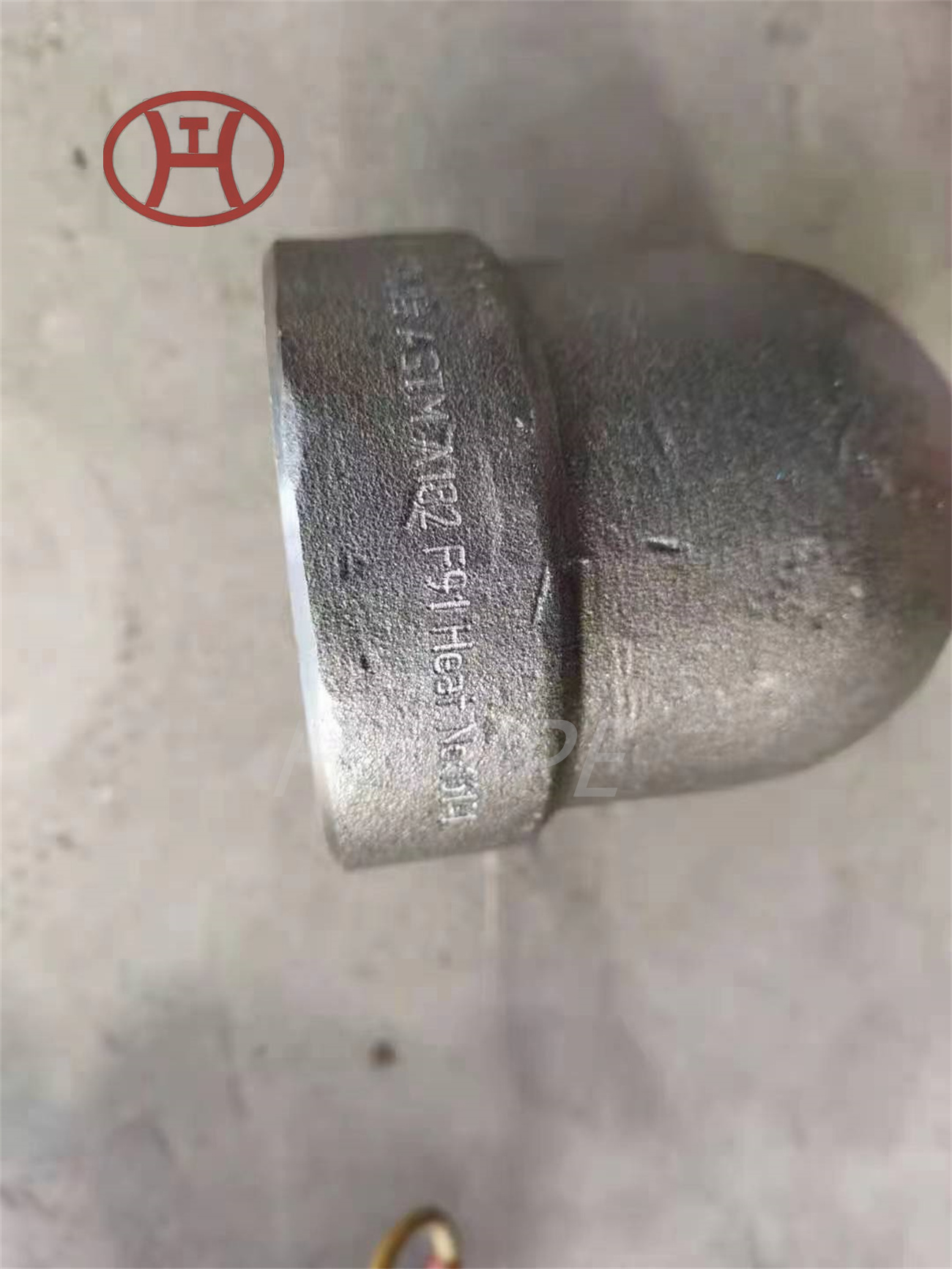

Alloy Steel A335 P9 Seamless Pipe Distributor, ASME SA 335 Alloy Steel P9 Pipe, Stockist of UNS K90941 Alloy Steel Pipe

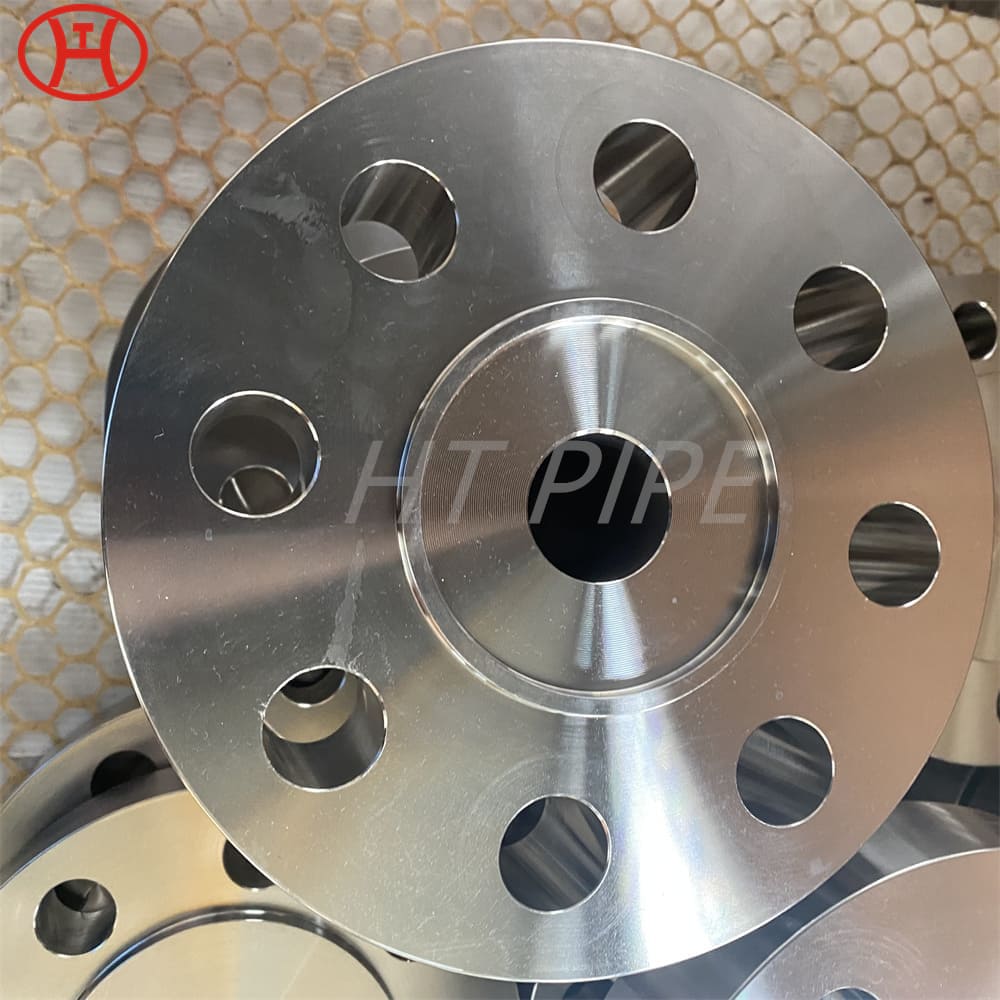

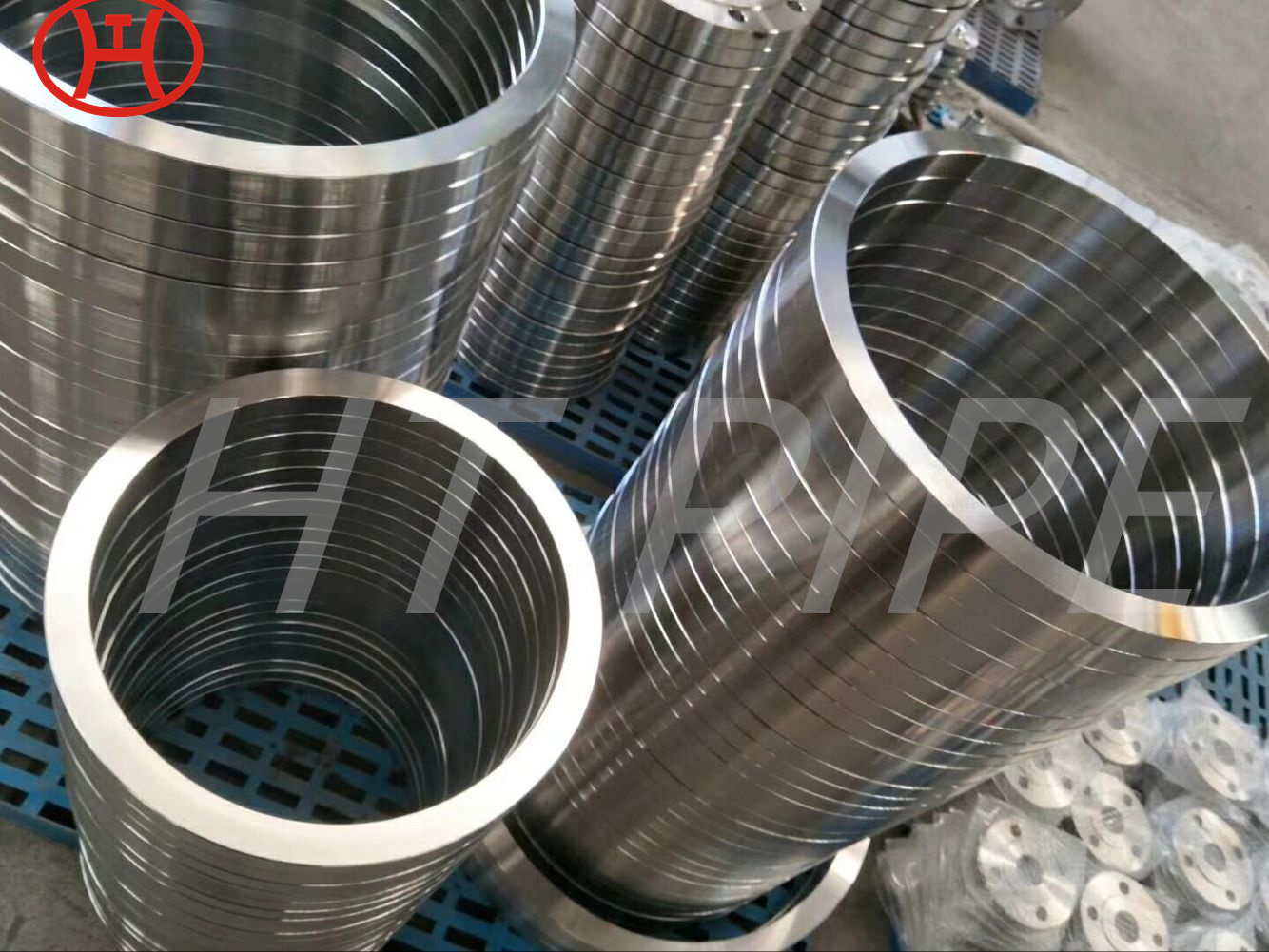

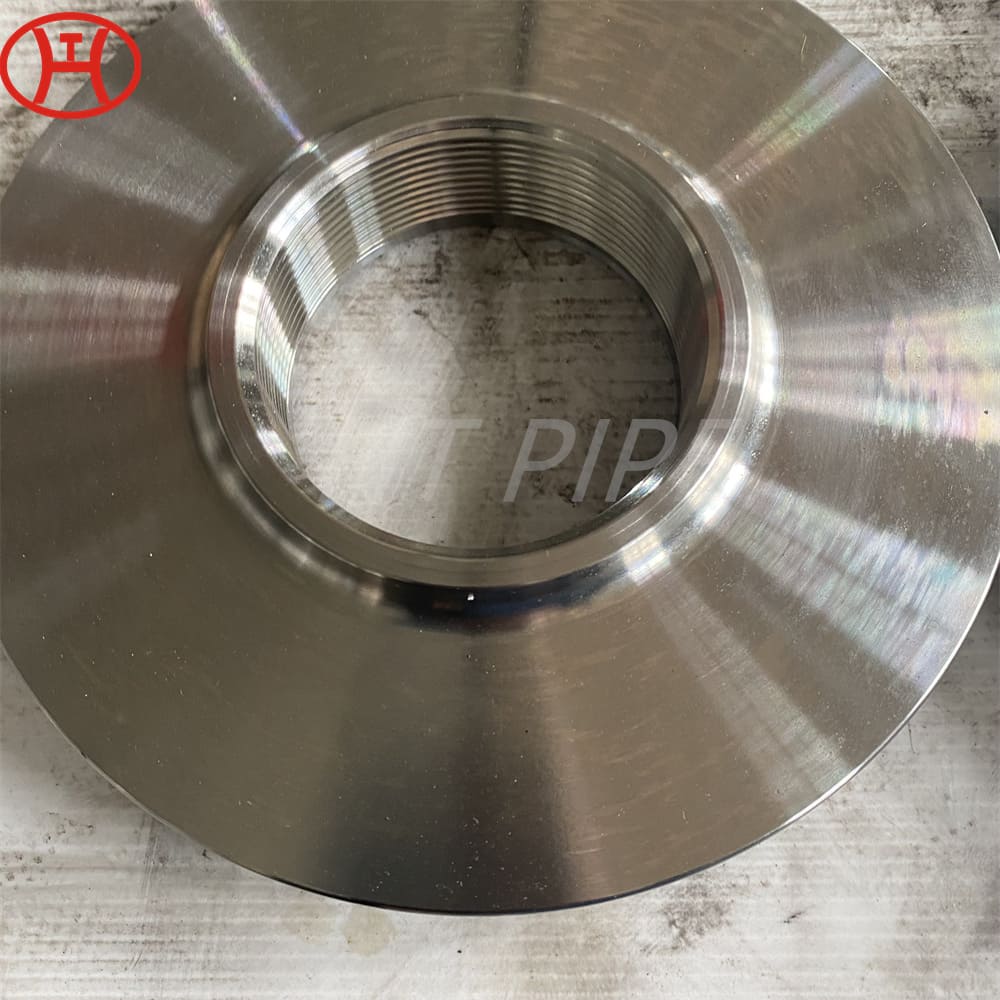

The key to the composition of chromium-molybdenum alloy P9 is the addition of chromium and molybdenum. Chromium or chromium increases high temperature strength, increases oxidation resistance and increases tensile, yield and hardness at room temperature. Molybdenum improves strength, elastic limit, wear resistance, impact quality and hardenability of ASTM A335 Grade P9 pipe. It increases the resistance to softening, inhibits grain growth of ASTM A335 Grade P9 pipe, and makes chrome steel less susceptible to embrittlement. At the same time, molybdenum improves strength, resistance, elasticity, hardenability and overall quality, and molybdenum ensures that P9 pipe is more resistant to softening, inhibits grain growth and reduces the chance of embrittlement. It is the only additive that increases the high temperature resistance (to 540-750°C) and also increases the corrosion resistance of ASTM A335 Grade P9.

The chromium in ASME SA335 pipe will increase oxidation resistance and provide high temperature strength, as well as better tensile and yield strengths and proper hardness at room temperature. Therefore, a335 p9 has excellent high temperature oxidation resistance. Except for chrome, astm a335 p9 alloy steel pipe coated with black paint or anti-corrosion oil shows good corrosion resistance. ASTM A335 Grade P9 pipe can also be galvanized with zinc. Galvanizing increases its resistance to atmospheric corrosion. In addition, when the chromium content is above 12%, it can be classified as stainless steel.

Chemical Composition of ASTM A335 Gr. P9 Pipes

| Grade | UNS Designation A | Carbon | Manganese | Phosphorus, max | Sulfur, max | Silicon | Chromium | Molybdenum | Others |

|---|---|---|---|---|---|---|---|---|---|

| P9 | K90941 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90–1.10 | — |

Mechanical properties of ASTM A335 Gr. P9 Pipes

| Grade | Tensile strength, min: | Yield strength, min: | Elongation Requirements | |||

|---|---|---|---|---|---|---|

| KSI | MPa | KSI | MPa | Longitudinal | Transverse | |

| P9 | 60 | 415 | 30 | 205 | 30 | 20 |