ASTM A403 SS 304 Buttweld Pipe Fittings Stainless Steel Tees

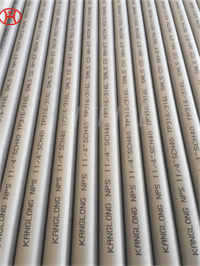

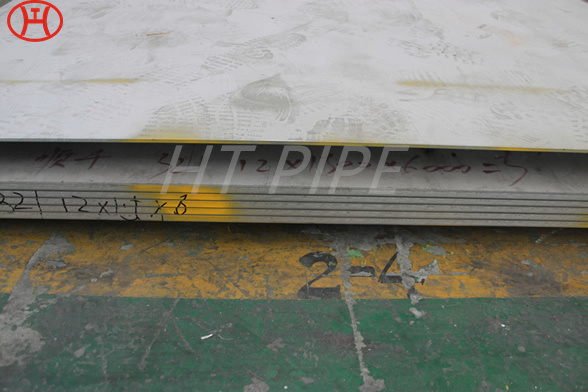

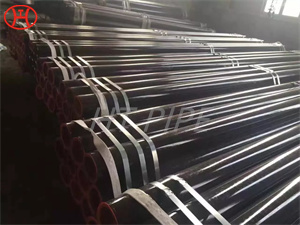

We are manufacturers of Stainless Steel 304 Butt Weld Fittings that are produced in a variety of designs, style, specifications, grades and sizes, with each fitting serving an industry’s need.

SS WP304 Pipe Fittings readily work hardens. Fabrication methods involving cold working may require an intermediate annealing stage to alleviate work hardening and avoid tearing or cracking. At the completion of fabrication a full annealing operation should be employed to reduce internal stresses and optimise corrosion resistance. SS UNS S30400 Buttweld Fitting has good machinability. Machining can be enhanced by using the following rules: Cutting edges must be kept sharp. Dull edges cause excess work hardening. Cuts should be light but deep enough to prevent work hardening by riding on the surface of the material. Chip breakers should be employed to assist in ensuring swarf remains clear of the work. Low thermal conductivity of austenitic alloys results in heat concentrating at the cutting edges. This means coolants and lubricants are necessary and must be used in large quantities.