ASTM A403 WP317L pipe fittings

ASTM A403 WP317L is a molybdenum bearing, low carbon content “L” grade austenitic stainless steel that provides improved corrosion resistance over 304L and 316L stainless steels. The low carbon provides resistance to sensitization during welding and other thermal processes.

Stainless steel grade 317L is a derivative of standard 317 stainless steel. The L next to the grade indicates a lower content of carbon. The lower carbon content in fittings produced from these stainless steel grades is what provides the alloy resistance to sensitization during practices that involve heat like welding and other thermal processes.

Due to the lower carbon content present in 317L pipe fittings, the alloy is often welded without the occurrence of intergranular corrosion. Usually, intergranular corrosion is a result of chromium carbide precipitation that happens on the surface of a metal that features a higher carbon content and is exposed to high temperatures for a protracted period.

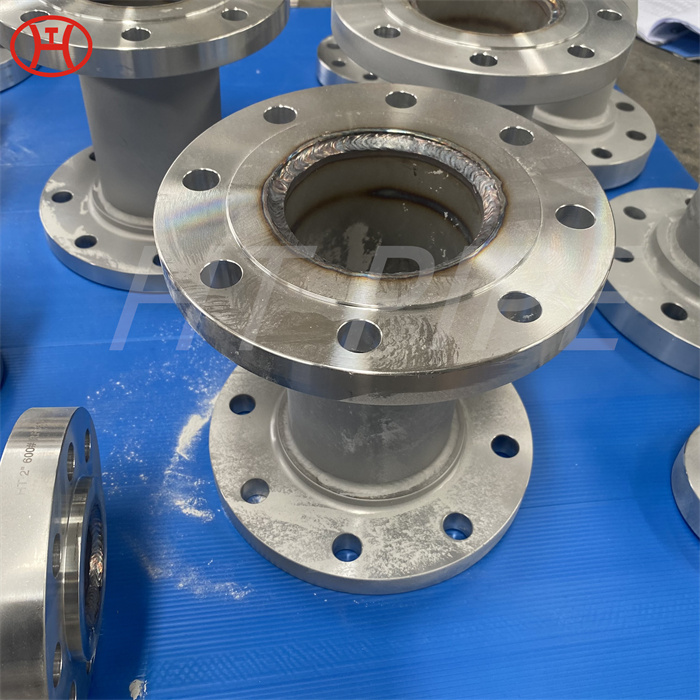

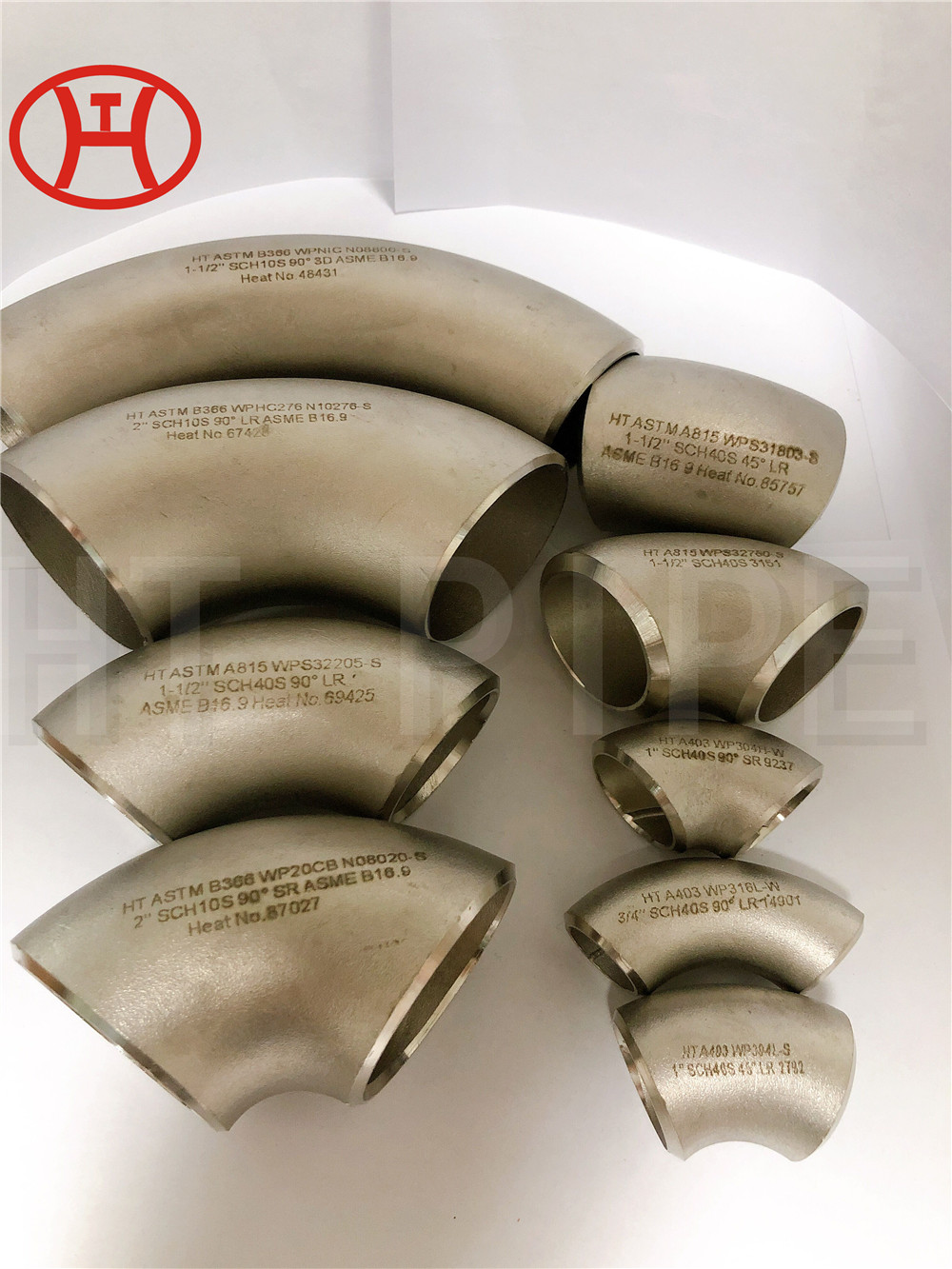

The 317L pipe fittings are the best to use equipment of piping used to change the direction of flow in the piping system of the industries. This is the way that the fittings are available in many types with which they are developed. The 317L pipe fittingss are available with the forged and buttweld fittings. The S31703 buttweld fittings are the most often used pipe fittings with the piping and tubing equipment. And the fittings are developed with the process of butt welding that is also known as the technique to use in industrial applications. The 1.4438 buttweld fittings are available to the clients in different types such as buttweld elbow, etc.

SS 317L PIPES FITTINGS CHEMICAL COMPOSITION

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo | Fe |

| SS 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.030 max | 18 – 20 | 11 – 15 | 3 – 4 | – |

STAINLESS STEEL 317L PIPES FITTING MECHANICAL PROPERTIES

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 317L | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |