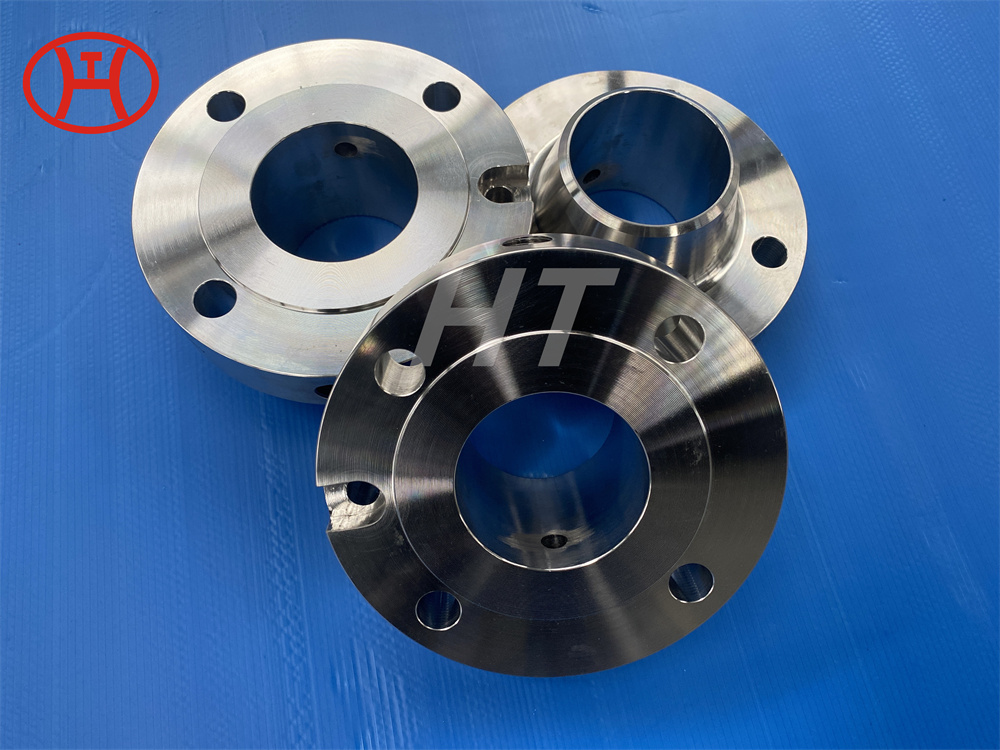

Astm A479 F44 S31254 254Smo 10Mm Diameter Bar Round 316L Squar Price Stainless Steel Rod Stands For Pipe fittings

Round bars are long cylindrical metal raw materials that are used in different industries. 254 SMO round bar is an austenitic stainless steel. These bars have good nickel, chromium and molybdenum chemistries. This makes these bars resistant to oxidation and all forms of corrosion.

DIN 1.4547 Flat And Square Bar, 254 SMO Round Bar Suppliers In China, View Price and Specification at HT PIPE

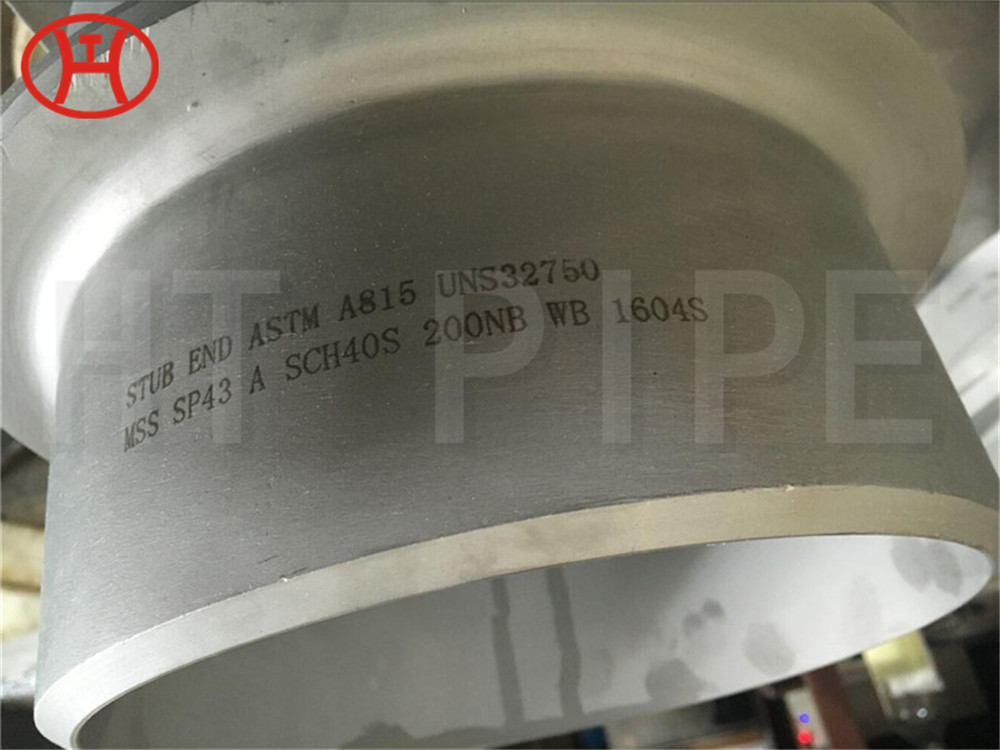

254 SMO stainless steel bar, also known as UNS S31254, was originally developed for use in seawater and other corrosive chlorine-containing environments. Alloy 254 round bar is considered a very high-end austenitic stainless steel; mainly composed of 19.5% to 20.5% chromium, 17.5% to 18.5% nickel, 6% to 6.5% molybdenum and 0.18% to 0.22% nitrogen.

254SMO is an austenitic steel designed for maximum resistance to pitting and crevice corrosion. Alloy 254 round bar contains high levels of chromium, molybdenum and nitrogen, making it particularly suitable for use in high chlorine environments such as brackish water, sea water, pulp mill bleach plants and other high chlorine process streams. In the new structure, alloy 254 round bar was found to be technically adequate in many cases and a lower cost alternative to nickel-based alloys and titanium. Alloy 254 round bar is easy to manufacture and solder.

Due to its high nickel and molybdenum content, ASME SA 276 stainless steel 254 SMO round bar is also frequently used in soaring chloride atmospheres. WNR 1.4547 rebar is also commonly used as a backup material for important parts of quality structures where SS 316L or SS 317L is damaged by crevice corrosion, chloride SCC or pitting corrosion.

254 SMO Chemical Composition

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

254 SMO Mechanical Properties

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |