ASTM A790 2507 Stainless Steel Seamless Pipe with Flange

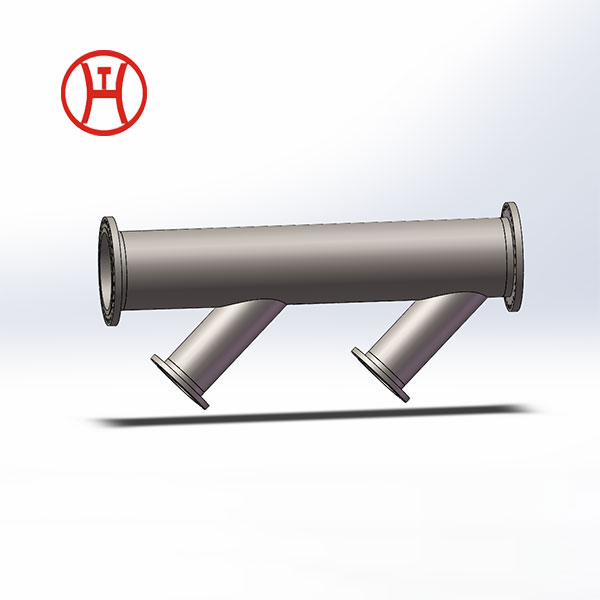

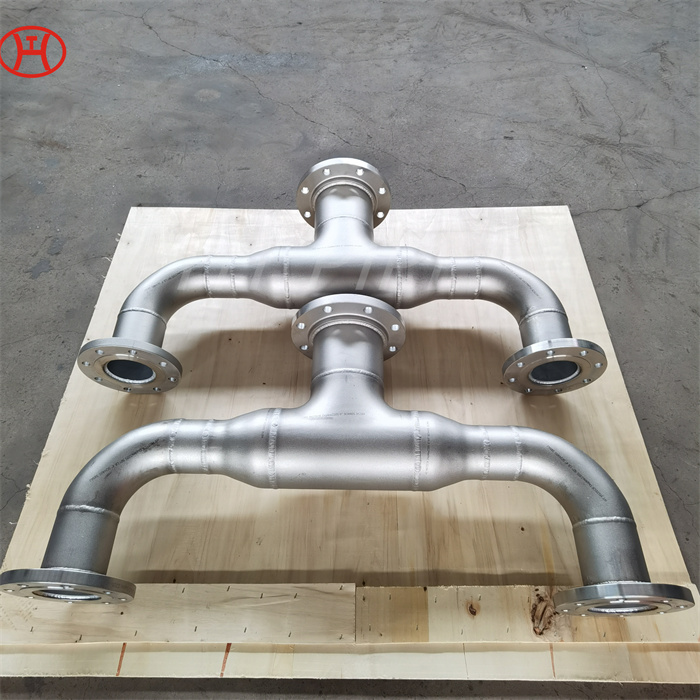

Customized Prefabrication Pipe Spools

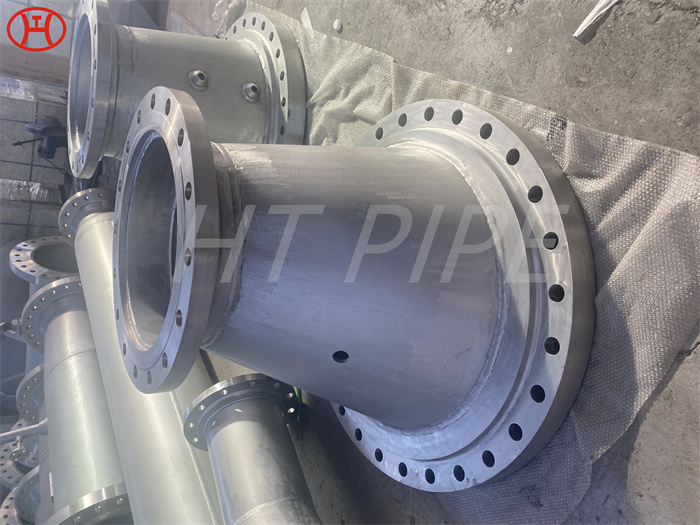

Pipe welded with Flanges

Pipe welded with Fittings

Flanges welded with Fittings

ASTM A790 2507 Stainless Steel Seamless Pipe with Flange,Super Duplex 2507 Seamless Pipe,UNS S32750 Seamless Pipe,ASTM A790 2507 Pipe,ASME SA790 UNS S32750 Pipe,DIN 1.4410 Seamless Pipe,F53 Pipe,Super Duplex 2507 Pipe with Flange, SS 2507 Seamless Pipe Price,UNS S32750 Seamless Pipe Manufacturer, Duplex 2507 Stainless Steel Seamless Pipe Supplier,Pipe Spools Fabrication,Pre-Fabrication Pipe Spools

ASTM A790 2507 stainless steel seamless pipe with flange is welded by 2507 stainless steel seamless pipe and flange. Super duplex 2507 seamless pipe is made of super duplex 2507 steel, which is a pipe made of high-performance duplex stainless steel. Duplex 2507 is a combination of austenitic and ferritic stainless steels with increased chromium, molybdenum and nitrogen content to provide exceptional strength, corrosion resistance and toughness. The seamless manufacturing process involves heating a billet of super duplex 2507 steel, which is then perforated with a mandrel to form a hollow tube that is more resistant to pressure.

UNS S32750 seamless pipe contains 25% chromium, 4% molybdenum and 7% nickel and is designed for applications requiring superior quality and corrosion resistance. ASTM A790 UNS S32750 pipe is able to perform well in the presence of high amounts of halogenated compounds like chlorine, bromine or fluorine, DIN 1.4410 seamless pipe is a custom solution for highly corrosive environments. The dual-phase composite structure and high alloy content of UNS S32750 make ASME SA790 UNS S32750 pipe not only resistant to stress-related corrosion cracking, but also resistant to pitting corrosion, crevice corrosion and localized corrosion in corrosive media.

How to choose stainless steel seamless pipe with flange, we need to consider various sizes, shapes and materials according to the application and requirements of the project. If super duplex 2507 pipe with flange is required, not only F53 seamless pipe needs to be considered, but also the required size, pressure class and type of flange needs to be specified. There are many types of flanges, including socket flanges, butt weld flanges, socket weld flanges, threaded flanges, and blind flanges. ASTM A790 2507 stainless steel seamless pipe with flange is widely used in offshore oil and gas exploration, chemical processing, and production of high-pressure pipelines, etc.

HT PIPE is duplex 2507 stainless steel seamless pipe supplier, providing pre-fabrication pipe spool customization service, our SS 2507 seamless pipe complies with international standard ASTM A790, flange complies with ASTM A182 standard. Our workshops and fabrication facilities are staffed with highly skilled craftsmen, pipe fitters, pipe fabricators, pipe welders, resulting in greater quality and efficiency and ultimately substantial cost savings to our customers. Welcome to consult.

Chemical Composition of ASTM A790 S32750 Pipe

| Grade | S32750 |

| C | 0.03max |

| N | 0.24-0.32 |

| P | 0.035max |

| Si | 0.8max |

| Mn | 1.2max |

| Mo | 3.0-5.0 |

| Ni | 6.00-8.00 |

| Cr | 24.0-26.0 |

| S | 0.02max |

| Cu | 0.50 |

Mechanical Properties Super Duplex 2507 Seamless Pipe

| Mechanical properties | S32750 |

| Tensile, min, ksi[MPa] | 116 [800] |

| Yield, min, ksi[MPa] | 80 [550] |

| Elongation, %(min) | 15 |

| Hardness, HB(max) | 300 |

UNS S32750 Stainless Steel Seamless Pipe Specification

| Pipe Specifications | ASTM A790 / ASME SA 790 |

| Pipe Standard | DIN, JIS, ASTM, EN, GB, AISI, ASME |

| Pipe Thickness | 0.3mm – 50 mm |

| Seamless Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe & Tube End | Plain End, Beveled End, Treaded Pipe. |