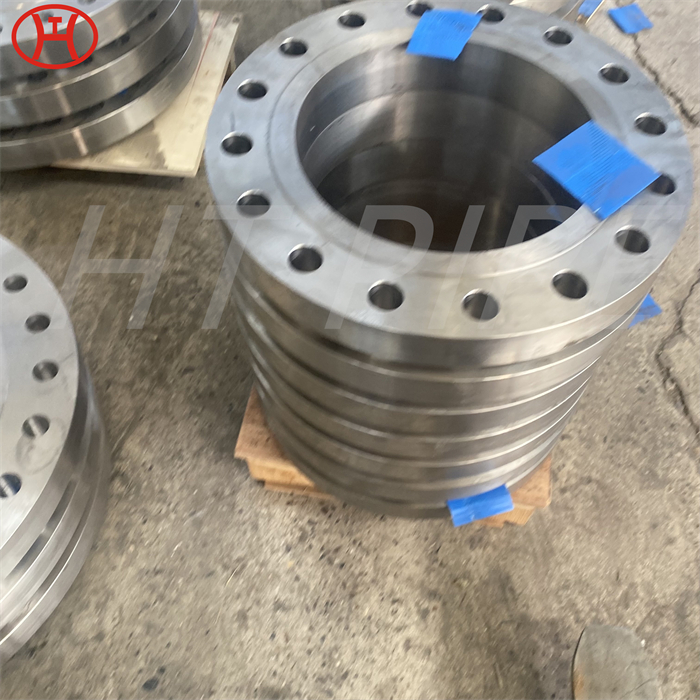

ASTM A182 SMO 254 WN Flange Manufacturer SMO 254 Orifice Flange Exporter

SMO 254 Flanges contain larger amounts of chromium in comparison with other steels and thus have good corrosion resistance. SMO 254 Slip-on Flanges contain about 10% of chromium.

A182 Stainless SMO 254 Flanges, SMO 254 Long Weld Neck Flanges, SS SMO 254 Ring Type Joint – RTJ Flanges, 6Moly Blind Flanges, Stainless Steel 254 Slip On Flanges, SMO 254 Weld Neck Flanges in China.

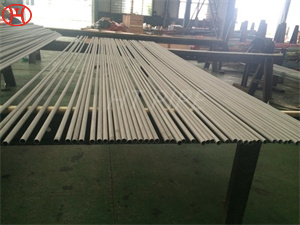

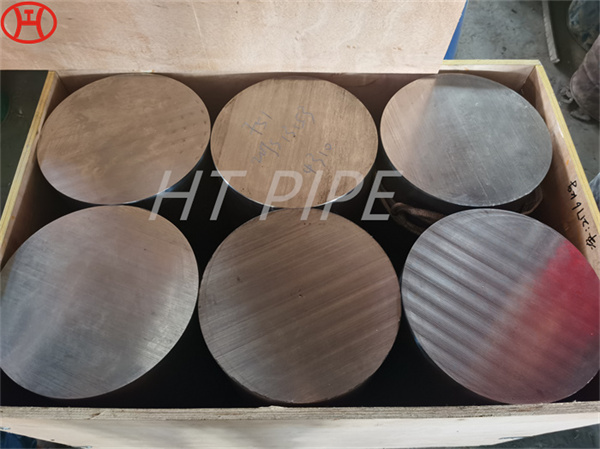

HT PIPE is a prominent exporter and supplier of SS 254 SMO Flanges, which has higher strength than conventional austenitic stainless steels. ASTM A182 Stainless Steel 254 SMO Flanges is quite tough to machine due to the extremely high work hardening rate and lack of sulfur content; however using sharp tools, overpowered machine tools, positive feeds, good amount of lubrication, and slow speeds tend to provide good machining results. UNS S31254 Weld Neck Flange Are Considered To Be The Perfect Option For Engineering Assemblies. In Fact, The Astm A182 F44 Material Can Be Used In Many Applications Such As In Constructional Works, High Strength Assemblies, As Well As Fitting Machine Components. The Material Tends To Oppose Wear And Tears In The Exertion Of High Torques. The SMO 254 Spectacle Blind Flange Also- Resists Crushing In High Machine Fittings. Additionally, The 6mo Flanges Properties Includes Corrosion Resistance, Which Is Useful For Services In Corrosive Media Containing Environments. The structure of the 6mo Plate Flange has been completely designed for application in heavy works. Generally, SMO flanges are able to withstand high temperatures, making them one of the safest options to be considered for assemblies. The 1.4547 Material is manufactured in different dimensions so that it can be easily fitted across a wide range of assemblies.

Alloy 254 SMO or the Astm A182 F44 Material is a very high end, molybdenum and nitrogen alloyed super austenitic stainless steel. SMO 254 RTJ Flange has a very low content of carbon. The 6mo Plate Flange displays outstanding resistance to crevice corrosion stress cracking, pitting, as well as corrosion fatigue uniform corrosion. The SMO 254 Spectacle Blind Flange is considerably much stronger as compared to the standard or conventional austenitic grade alloys. The tensile strength of the ANSI B16.5 SMO 254 Orifice Flange is nearly two times that of grade 300 series stainless steel. The UNS S31254 Weld Neck Flange is also characterized by its high ductility as well as high impact strength. With high levels of chromium, molybdenum, and nitrogen content , the alloy is frequently used in high chloride containing environments. For example, the UNS S31254 Pipe Flange is used in environments such as seawater, brackish water, pulp mill bleach plants, and other chloride process streams. In quite a few applications the Smo 254 Flanges has even been found to be a more cost effective solution for high nickel and titanium content alloys. Since the content of both these elements is less, the price of the consumed alloy is lesser. SMO 254 Threaded Flanges are another type of flange which is characterized by tapered threads and can be employed in high-pressure systems because of their small diameter and is extensively used in many industries.

SMO 254 FLANGE INTERNATIONAL STANDARDS

| STANDARD | WERKSTOFF NR. | UNS | SIS | BS | GOST | AFNOR | EN |

| SMO 254 | 1.4547 | S31254 | 2378 | – | – | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

SMO 254 FLANGES CHEMICAL COMPOSITION

| Grade | C | Mn | Si | Cu | S | P | Mo | Ni | Cr |

| SMO 254 | 0.02 | 1 | 0.08 | 0.5-1.0 | 0.01 | 0.03 | 6.0-6.5 | 17.5-18.5 | 19.5-20.5 |

SMO 254 FLANGES MECHANICAL PROPERTIES

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |