ASTM A815 Stub End 2205 Butt-welding Pipe Fittings

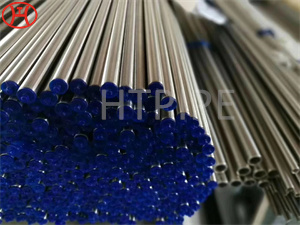

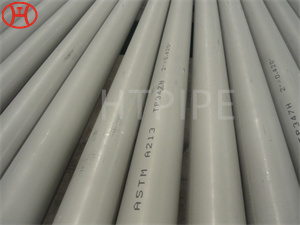

Inhibiting deformation and cracking at high temperatures, the dual phase steel S31803 / S32205 reducer is superior to common steel parts in the chemical industry that are susceptible to chloride stress corrosion cracking. With flue gas desulfurization machinery. Tees such as ASME A182 Duplex Steel S31803/S32205 are known to have good resistance to high toxicity and elasticity.

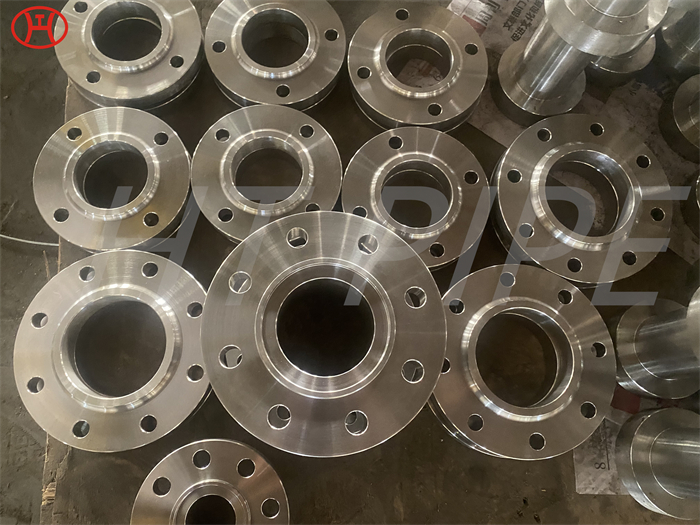

These are especially recommended for corrosive applications in a variety of environments. These fittings are enhanced by the ferritic and austenitic alloy properties of a dual phase structure. Therefore, it has excellent resistance to stress corrosion cracking. It has excellent strength as well as ease of manufacture and increased corrosion resistance. Additionally, these grades can be easily welded with filler materials using standard welding methods. The extra nitrogen provides a shielding effect during the soldering process. Due to its high strength, 2205 dual-phase steel has very low machinability, which is much lower than that of 304 grades. In addition, dual-phase steel has good formability and is used to produce 2205 dual-phase steel butt welded pipe fittings and 2205 dual-phase steel forged pipe fittings. So, that’s the subject of this article. Before continuing, let’s take a look at the pipe fittings.