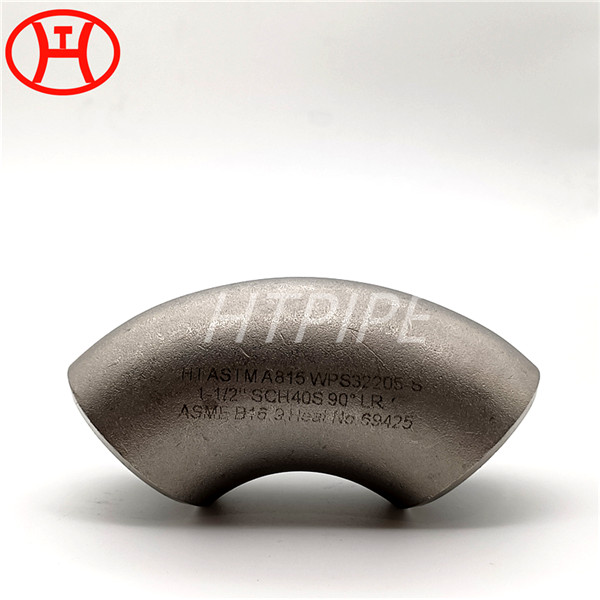

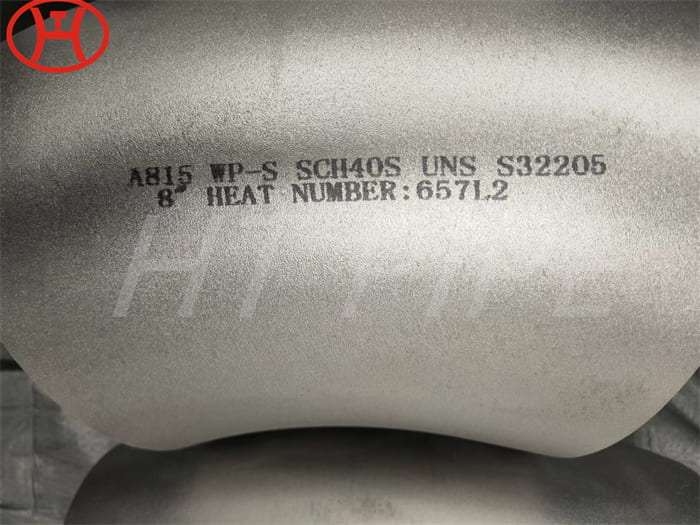

ASTM A815 WP S31803 Duplex Steel 45 Degree LR Elbows

ASTM A815 UNS S32205 Long Radius Elbow is used in turning pipe direction and is also resistant to chloride and sulfide environments. These ASME B16.9 Duplex Stainless Steel Seamless Fittings have a higher chromium content.

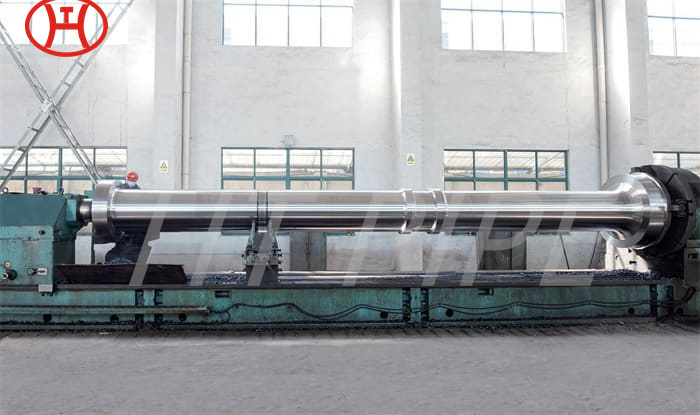

ASTM A815 2205 Duplex Stainless Steel Buttweld Fittings Manufacturer in China

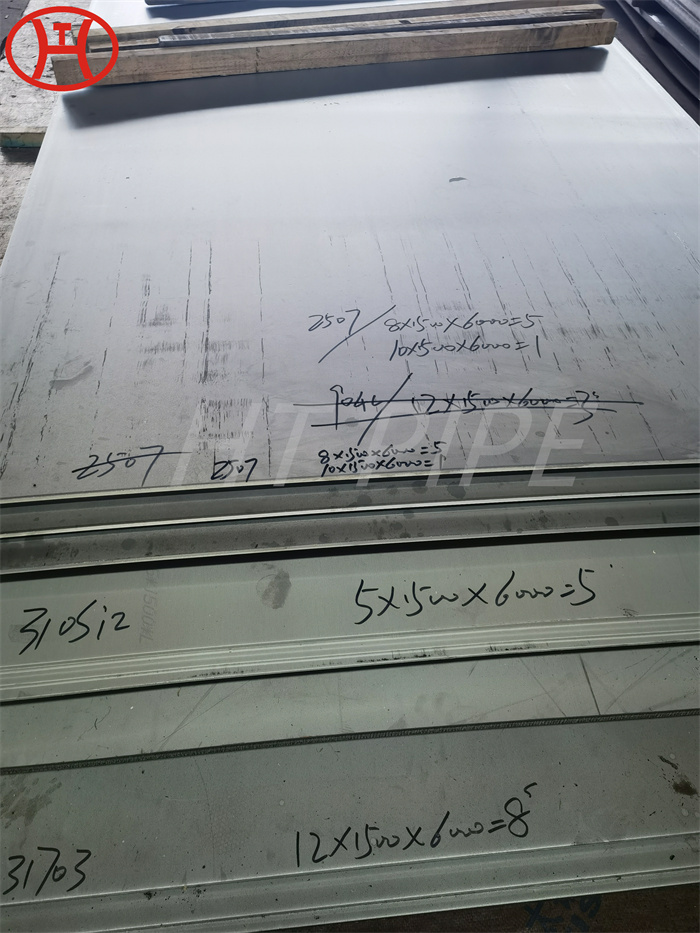

ASTM A815 specification covers two general classes, WP and CR, of wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings of seamless and welded construction. Class WP fittings are subdivided into four subclasses: Classes WP-S, WP-W, WP-WX, and WP-WU. The material for fittings shall consist of forgings, bars, plates, or seamless or welded tubular products. A fitting is used to change the direction of the pipe. The simplest way to do it is to bend the pipe. However, S32205 elbow will stretch and thin out the outer walls of the pipe. S32205 elbow will also thicken the inner wall of the pipe. 2205 duplex stainless steel fittings are renowned for having austenitic and ferritic microstructures. ASTM A815 2205 Duplex Stainless Steel Elvows display the properties of both classes. Improved localized corrosion resistance is displayed by ASME SA815 Duplex Steel Butt Weld Pipe Fittings when compared to 316 and 317 grades.

Ordinary steel fittings are sensitive to chloride stress corrosion cracking. However, ASME SA815 Duplex Pipe Reducers are better as they restrain deformities and avoid corrosion cracking even under high temperatures. UNS S31803 Duplex Steel Tee is said to have amazing toxic resistance and elasticity due to which they are used in the gas desulfurization industry. WERKSTOFF NR. 1.4462 End Cap have high resistance to intergranular corrosion and are therefore used in terminating connections. HT PIPE has grown in the past few decades and there are a variety of products available in the market. ASTM A815 UNS S32750 Pipe Fittings are one of those products and are available in various sizes, shapes, and dimensions. ASTM A815 UNS S32760 Pipe Fittings are designed to be resistant to corrosion and are said to have perfect weldability. These Super Duplex S32750 Buttweld Fittings are resistant to erosion corrosion and fatigue. They have a mixed microstructure of 50% austenitic and 50% ferrite.

| Specifications Standard | ASTM A815 /ASME SA815 |

| Duplex 2205 Pipe Fittings Size Range | Welded Fittings: 1/2″ – 48″ |

| Seamless Fittings: 1/2″ – 10″ | |

| Connection | Welding |

| Type | DN15 to DN1200 |

| Origin & Mills | Indian, European, Korean, Japanese, Ukraine, USA, Russian |

| Radius of bending | R=3D, 1D, 8D, 10D, 5D, 2D, Custom MSS Sp-43, 6D |

| Duplex 2205 Pipe Fittings Manufacturing process | Forge, Press, Cast, Push etc. |

| Thickness | SCH10, SCH40, XS, SCH30, SCH 160, SCH 80, SCH 140, SCH60, SCH20, STD , SCH 120, SCH 100, XXS |

| Pressure Ratings | 2000#, 150#, 6000#, 3000#, 9000# |

| Export to | Abu Dhabi , Gimhae-si, Pimpri-Chinchwad,Montreal, Ankara, Ludhiana, Rajkot, Damilimeteram, Santiago, Noida, Karachi, Gujarat, Janeiro, Melbourne, Surat, Kuwait, Tau, Manama, Hyderabad, Ernakulam, Thiruvananthapuram, Ranchi, Nagpur, Gurgaon, Riyadh, Howrah, Baroda, Indore, Chennai, Bogota, Mexico, Bangalore, Ahvaz, Kanpur, Vadodara, Tehran, Perth, London, Khobar, Lagos, Sydney, India, Mumbai, Kolkata, Istanbul, Caracas, Muscat, Coimbatore, Jamshedpur, Courbevoie, Calgary, Bengaluru, Ahmedabad, New Delhi, Port-of-Spain |

| End Connections: | socket weld and Threaded |

| Duplex 2205 Pipe Fittings manufacturer | 90º Tee, Elbows, Pipe Cap, Stub End, 45º Elbows, Crosses, Pipe Bend, Reducers |

| Dimensions | ASME B16.28, BS4504, MSS-SP-43, ASME/ANSI B16.9, BS1560, BS4504, BS10 |

| Elbows | Angle : 2.0D, 1.5D, 5D, 3D, 1.0D, 6D, 4D, 2.5D, 7D-40D . |

| Standard: JISB2312, MSS SP-75, 22.5 deg, JISB2313, 30deg, ASME B16.9, 180 deg, 45 deg, JISB2311 BS, DIN2605, 90 deg, GB | |

| ISO | |

| Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| Third Party Inspection Report, etc |