ASTM ASME A SA 150 (N) Carbon Steel Flanges

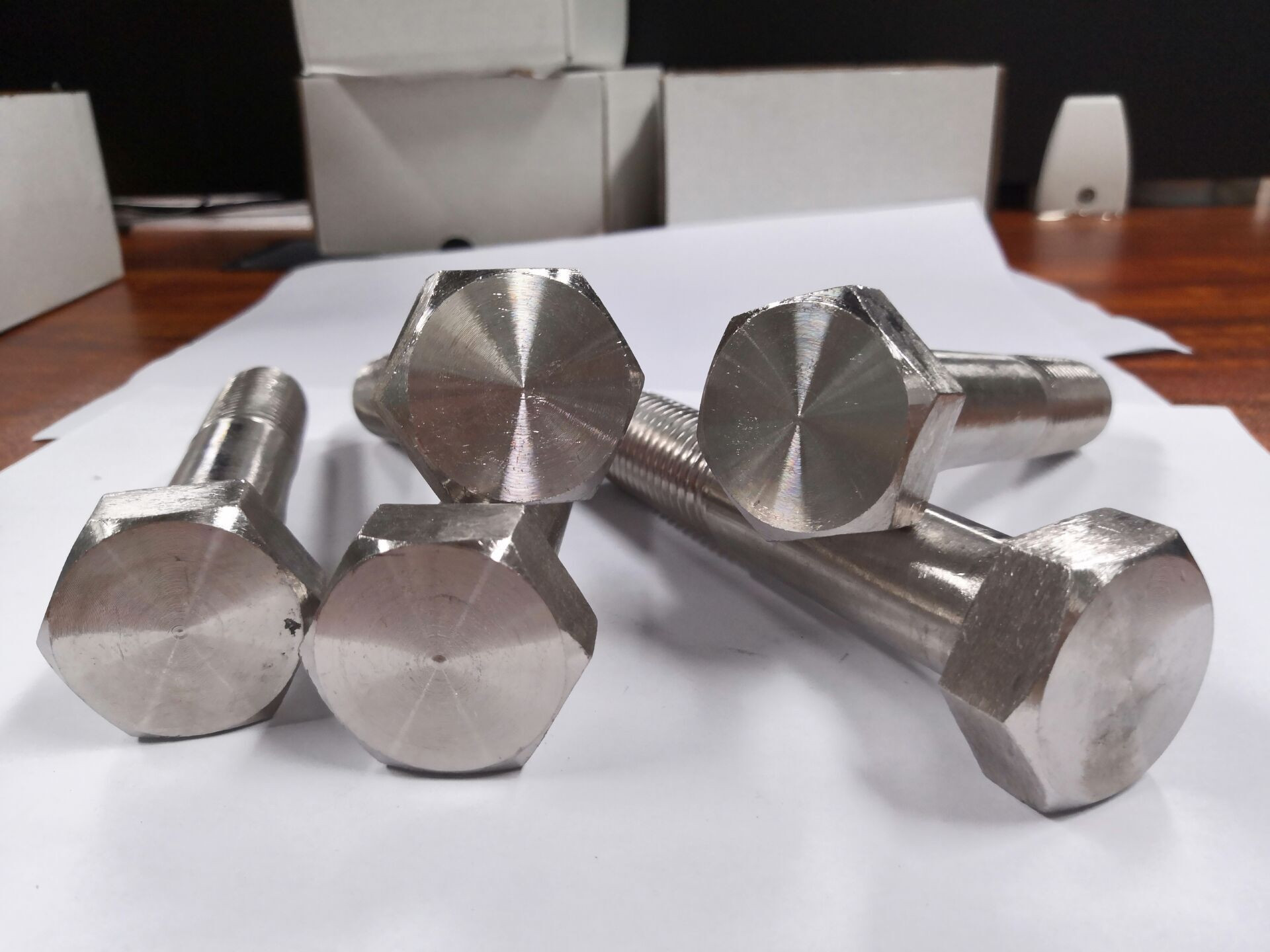

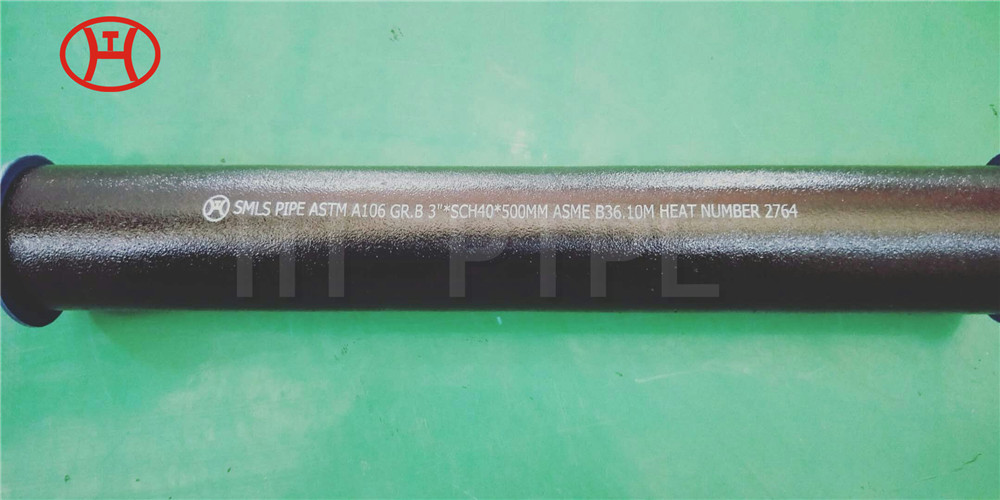

Carbon steel forgings, manufactured in accordance with ASTM A105, are generally used for piping applications.

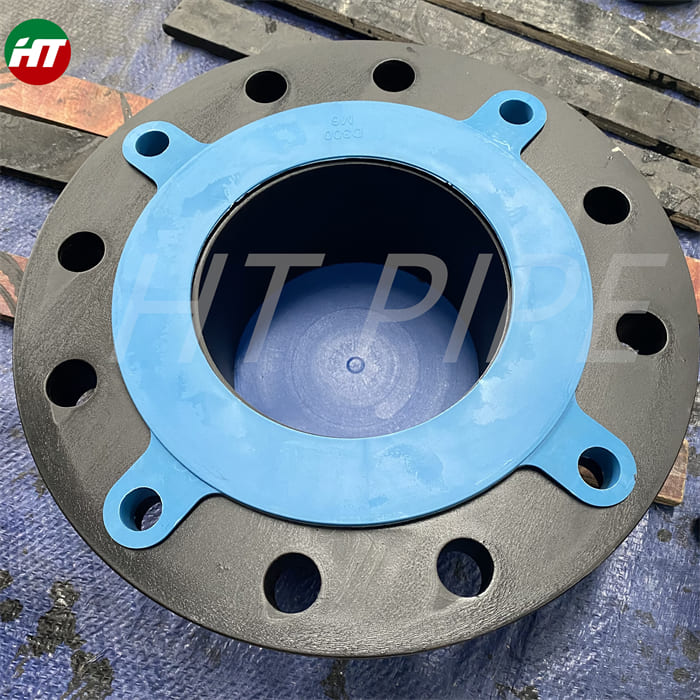

Manufacturer Of A105 Carbon Steel Plate Flange, Stockholder Of Carbon Steel RTJ Flange, ASTM A105 Carbon Steel Flanges, Best Price of ASTM A105 WNRF Flanges Exporter, ASME SA105N Carbon Steel Class 300 Flange Wholesaler, Carbon Steel A105N Flat Flange, ASTM A105 Carbon Steel EN 1092-1 Flanges Traders in China.

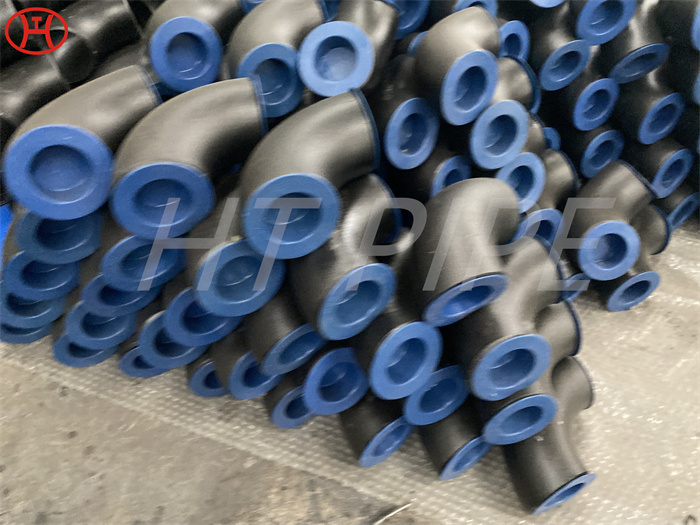

The flange is second most used joining method after welding. Flanges are used when joints need dismantling. It provides flexibility for maintenance.flange connnects the pipe with various equipment and valves. Breakup flanges are added in the pipeline system if regular maintenance in required during plant operation.

These forged carbon steel piping components (including flanges, fittings, and valves, etc) are used for ambient- and higher-temperature service in pressure systems. The A105N, which is designated with a suffix ¡°N¡±, denotes that the A105 forging shall be furnished in normalized condition. If the forgings are used for piping applications of ASME BPVC or ASME B31, the material shall be its identical equivalent of SA-105 or SA-105N. In short, the heat treatment of normalization distinguishes A105N from A105, or SA-105N from SA-105. ASTM A105 Flange is a specification of flanges. The specification can include different grades of stainless steel material made flanges. The flanges are of forged carbon steel and are meant for high temperature services.

A flanged joint is composed of three separate and independent although interrdlated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls are required in the selection and application of all these elements to attain a joint, which has acceptable leak tightness.

Flanges are used to connect 2 ends of a pipe or to end a pipe. They are available in various materials. Carbon Steel Flanges are one such type of flange that is usually made up of carbon steel. This material provides properties such as resistance to corrosion, excellent durability, and finishing in goods.

Standard Specification For Carbon Steel ASTM A105 / A105N Industrial Flanges

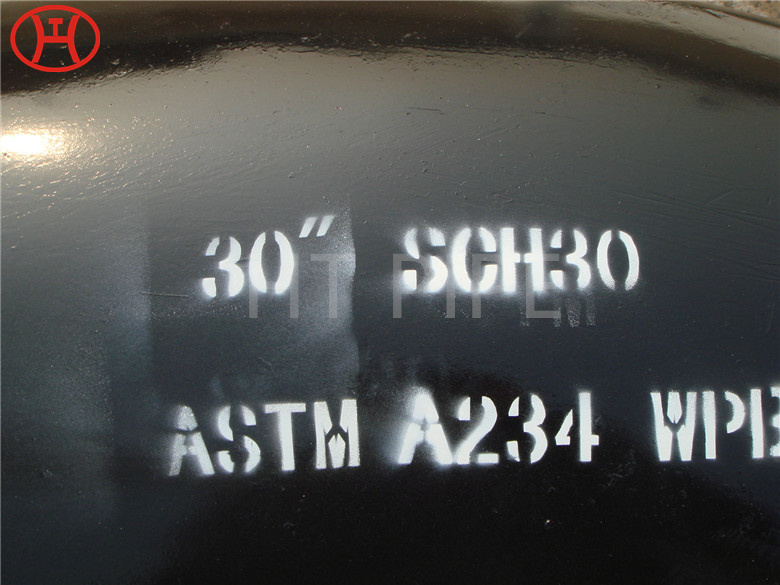

Specifications : ASTM A105 / ASME SA105, A105N

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2″ to 48″

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

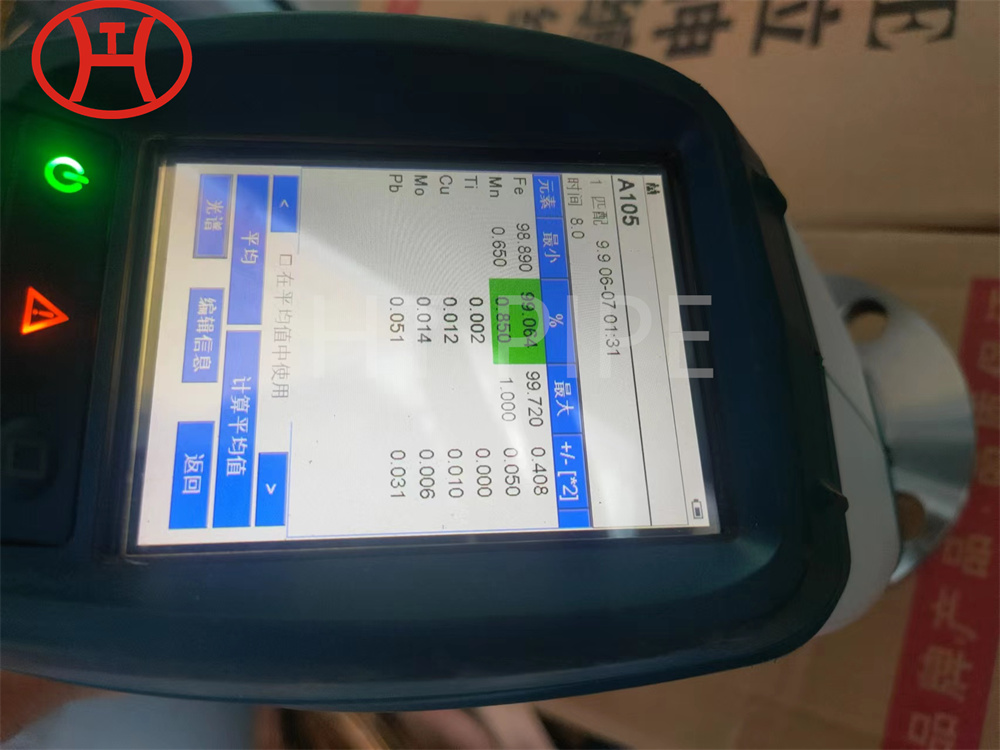

ASTM A105 Carbon Steel Flanges Chemical Composition

| Element | Composition %, Note C |

|---|---|

| Carbon | .35 max |

| Manganese | .60-1.05 |

| Phosphorus | .035 max |

| Sulfur | .040 max |

| Silicon | .10-35 |

| Copper | .40 max, note A |

| Nickel | .40 max, note A |

| Chromium | .30 max, note A,B |

| Molybdenum | .12 max, note A,B |

| Vanadium | .08 max, note A |

| Note A – The sum of copper, nickel, chromium, molybdenum and vanadium shall not exceed 1.00% Note B – The sum of chromium and molybdenum shall not exceed .32% Note C – for each reduction of 0.01% below the specified carbon maximum (.35%), an increase of .06% manganese above the specified maximum (1.05%) will be permitted up to a maximum of 1.65% |

|

Flanges A105 Material Mechanical Properties:

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |