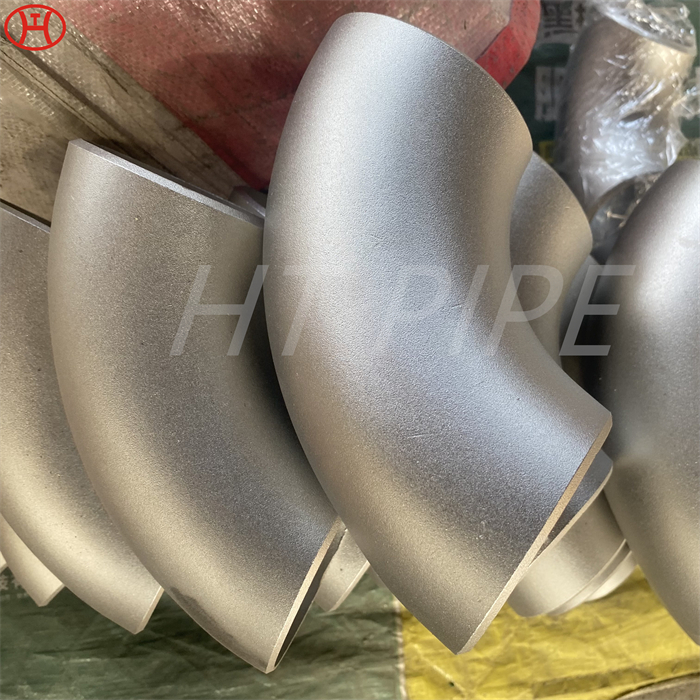

ASTM ASME SB 425 alloy 825 round steel bar UNS N08825 Nickel alloy bar

One of the main benefits of using nickel alloys is that they tend to be resistant to high temperatures. ASTM B425 UNS N08825 bar stock has a nickel content between 38% and 46% and is able to withstand a moderately high temperature range without affecting its tensile strength. This property is particularly useful in applications involving nuclear fuel reprocessing, where Incoloy 825 Square bar is considered a value-add. In nuclear reprocessing, the process involves separating chemicals such as fission products and excess uranium from spent nuclear fuel.

ASTM B425 UNS N08825 Flat Bar and Inconel Alloy 825 Hex Bar supplier in China, DIN 2.4858 Rod and ASME SB 425 UNS N08825 Square Bar manufacturer

The Incoloy 825 alloy consists of nickel, chromium, and iron in the chemical composition along with titanium, copper, and molybdenum. The Incoloy 825 Round Bar is popular for its high resistance in many chemically corrosive environments. The N08825 round baris primarily known for providing excellent resistance to crevice corrosion, pitting, stress corrosion cracking, and intergranular corrosion. The presence of chromium in the N08825 round bar improves its resistance against various oxidizing salts, nitrates, and nitric acids. Proper heat treating the titanium-based Nickel Alloy 825 Rod helps to stabilize it against intergranular corrosion sensitization.

The UNS N08825 Square Bar is known for its resistance against localized and general corrosion in a wide range of environments. The excellent mechanical properties of Din 2.4858 Flat Bar make it appealing for different industries like nuclear fuel processing, pollution control, acid production, etc. The 825 Incoloy Hex Bar is also used in making equipment that handles radioactive waste. Our ASME SB425 UNS N08825 Square Bar goes through several quality and safety checks in government-approved labs conducted by third parties before they are delivered.

While most stainless steels exhibit failure due to chlorine ion stress related corrosion cracking, the adequate content of nickel in N08825 round bar, makes it useful in conditions that are conducive to corrosion. The mechanical properties of Alloy 825 Flat Bar are good at temperatures at 1000°F. However, the use of the alloy beyond 1000°F results in a loss in ductility and impact strength due to microstructural changes.

Incoloy 825 Round Bar Specification

| Specification | ASTM B425 UNS N08825, SB 425 |

| Standard | ASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS |

| Alloy 825 Round bar size | Diameter: 3~800mm |

| ASTM B425 N08825 Angle bar size | 3*20*20mm~12*100*100mm |

| Nickel Alloy 825 Square bar size | 4*4mm~100*100mm |

| B425 N08825 Billet Size | 1/2″ to 495mm Diameter |

| 2.4858 Incoloy 825 Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed |

| Technique | ASTM B425 Gr 825 Hot Rolled, Cold Rolled, Cold Drawn, Forged |

| Where we export | USA, UAE, Malaysia, Poland, Singapore, Canada, Australia, Iran, UK, Italy |

| Form | Round, Rod, Ingot, Billet, Rings, Hex, T-Bars, Precision-Ground, Rectangle, Forging, Half-Round, Blocks, Angle, I/H, Hollow, Flat, Round-Rod, Square, Triangle, Profiles, Channel, Threaded |

| Our Incoloy 825 Round Bar conforms to NACE MR0175/ISO 15156 | |