ASTM ASME SB 446 alloy 625 bar metal UNS N06625 Nickel alloy bar

Inconel 625 round bar is one of the more common grades of Inconel round bar available. The Round Bar is AMS 5666 compliant. Inconel 625 can be used in a variety of applications. Inconel 625 has high strength, excellent fabrication and excellent corrosion resistance. The viable temperature range for Inconel 625 starts at cryogenic temperatures up to 1800¡ãF.

Nickel Alloy Inconel 625 | UNS# N06250 is a nickel based super-alloy that demonstrates high strength properties, is resistant to high temperatures, has remarkable protection against oxidation and corrosion.

These alloys are types of materials that are highly resistant to corrosion and oxidation in extreme environments where excessive pressure and heat are present. This alloy Inconel bar, when heated, forms a passivating oxide layer that protects its outer surface from further attack – making it stand across a wide temperature range and high-temperature applications.

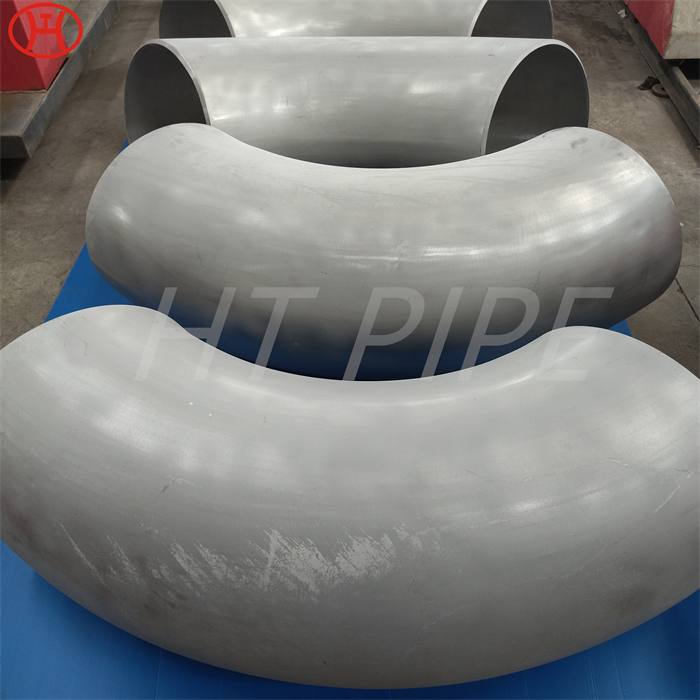

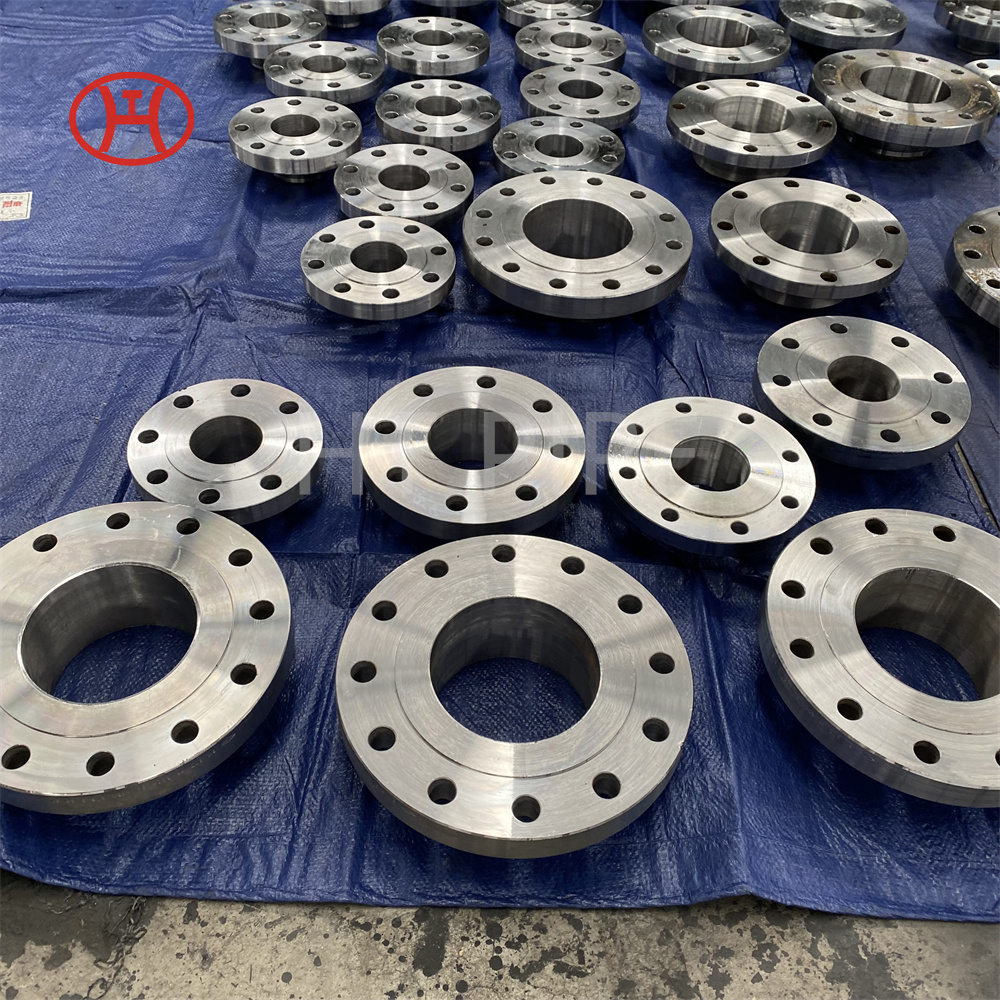

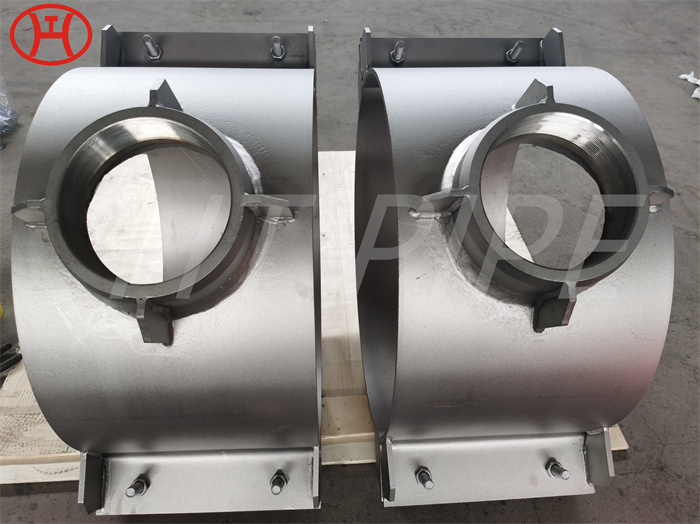

Nickel Alloy Inconel 625 shows the ability to withstand high stress environments and has excellent fabricability. Due to these properties, Nickel Alloy Inconel 625 is widely used for sea-water applications because of high corrosion-fatigue strength, high tensile strength, and excellent resistance to chloride chemicals. Often used in propeller blades, propulsion motors, fittings for submersibles, oceanographic instrumentation and many other applications.

Precipitation strengthening and solid solution strengthening develop the alloy’s high-temperature strength. These alloys are really very resistant to attacks from hot gases and oxidizing chemicals.

Features of Inconel 625 round bar:

- Highly resistant to seawater

- Great resistance to chloride pitting

- Resistant to caustics

- Can withstand chloride ion stress corrosion cracking

| CHEMICAL COMPOSITION | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C <=0.10% | Cr 21.5% | Co <=1.0% | Fe <=3.0% | Mo 9.0% | |||||

| Ni 65.05% | Nb 3.65% | Ti <=0.50% | |||||||

| PHYSICAL PROPERTIES | ||||||

|---|---|---|---|---|---|---|

| Density | Electrical conductivity (% IACS) | Thermal conductivity (BTU-in/hr-ft²-°F) | Specific heat capacity | Thermal expansion (1/°F) | Melting Point (°F) | |

| 0.305 | 1.34 | 68 | 0.098 | 0.00000711 | 2295 | |

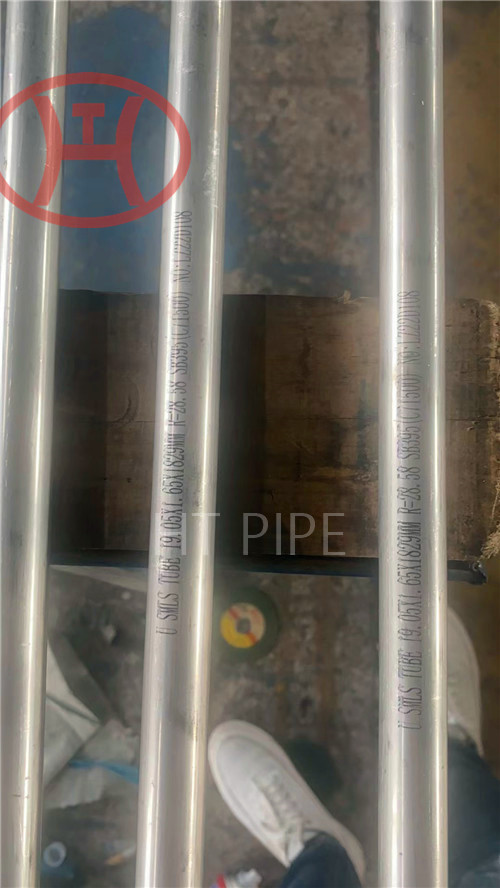

Product Types Round Bar Square Bar Hexagon Bar Flat Bar

Surface Black or Bright or Pickling white

Standard SUS, AISI, DIN

Manufacture Technique Hot Rolling, Cold-drawing

Diameter 5~500mm

Length ¨Q12M or As Per Clients’ Requirements.

Diameter Tolerance H7 H9 H10 H11

Material Grade Nickel Alloy ASTM/ASME SB 425 Alloy 825/Incoloy 825/UNS N08825

ASTM/ASME SB 446 Alloy 625/UNS N06625

ASTM/ASME SB164 Monel 400/Alloy 400/UNS N04400

ASTM/ASME SB 408 Alloy 800HT/Incoloy 800HT/UNS N08811, Alloy 800/Incoloy 800/UNS N08800, Alloy 800H/Incoloy 800H/UNS N08810

ASTM/ASME SB 649 Alloy 925/Incoloy 925/UNS N09925, Alloy 926/Incoloy 926/UNS N08926, Alloy 31/UNS N08031

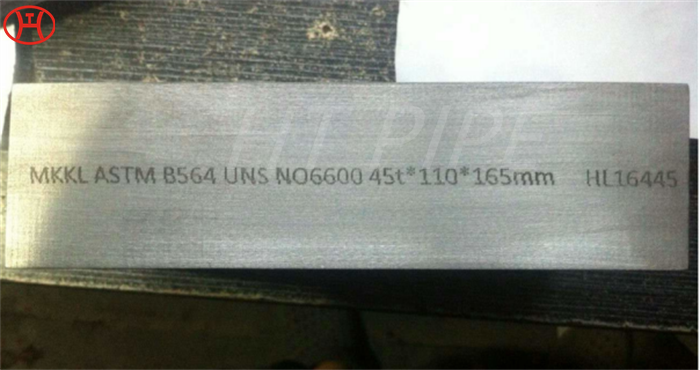

ASTM/ASME SB 166 Alloy 600/Inconel 600/UNS N06600,Alloy 601/Inconel 601/UNS N06601

ASTM/ASME SB160 Alloy 200/UNS N02200, Alloy 201/UNS N02201

ASTM/ASME SB 472 Hastelloy C-276/UNS N10276,Alloy 926/Incoloy 926/UNS N08926, Alloy 31/UNS N08031,Alloy 20/N08020, Alloy C-22/Hastelloy C-22/N06022, Alloy 600/Inconel 600/UNS N06600, ASTM/ASME SB 473 Alloy 20/UNS N08020

ASTM/ASME SB 574 Hastelloy C-276/UNS N10276

ASTM/ASME SB 637 Alloy 718/Inconel 718/N07736