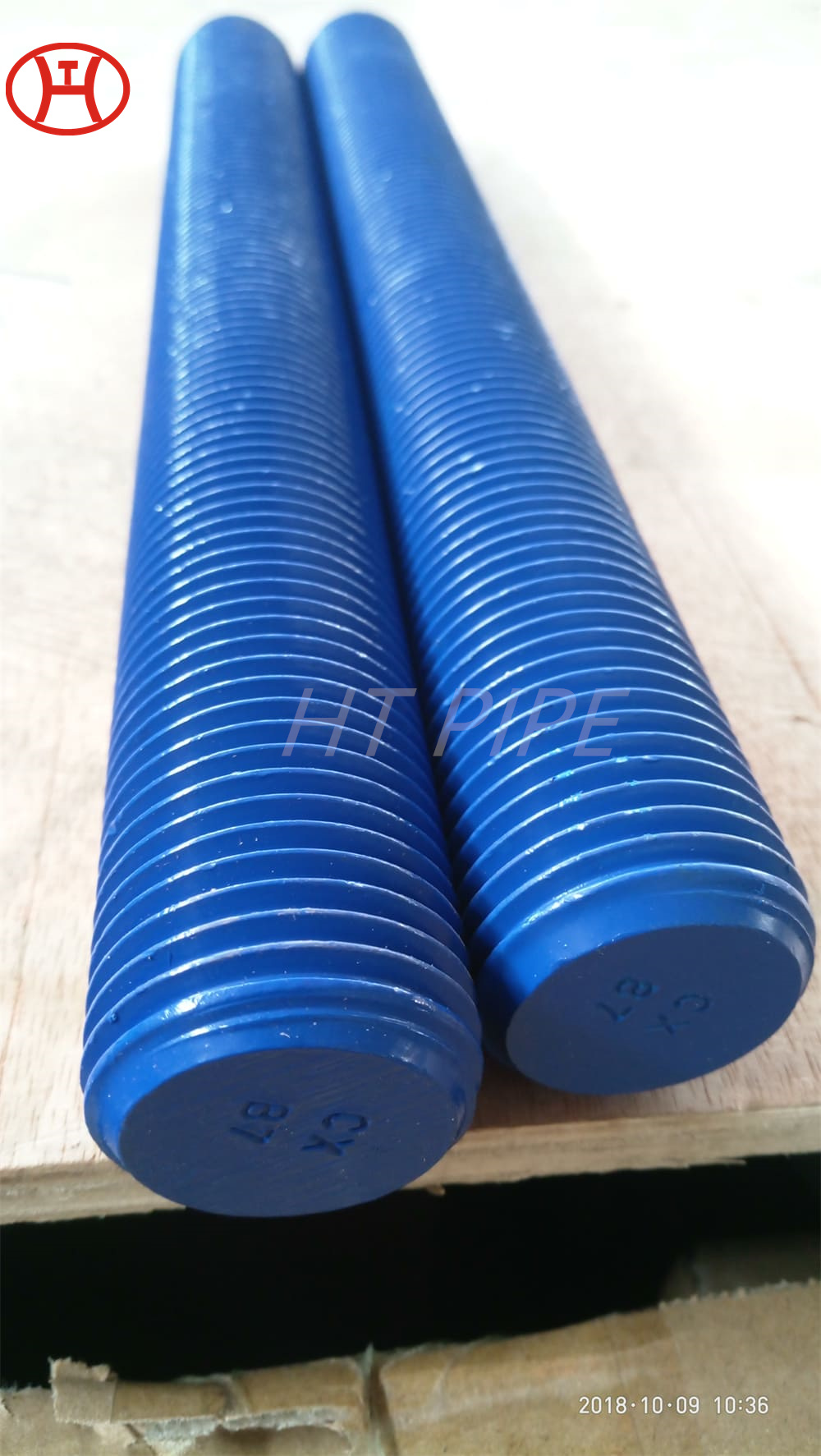

ASTM ASME SB 574 bright round bar UNS N10276 Nickel alloy bar

Hastelloy C276 alloy hollow rods tend to exhibit excellent resistance to localized corrosion and oxidizing media as well as reducing media.

Hastelloy Round Bar Suppliers, Buy From UNS N10276 Bar, Hastelloy C276 Rod, Alloy C276 Hex Bar Manufacturer In China At Discounted Prices

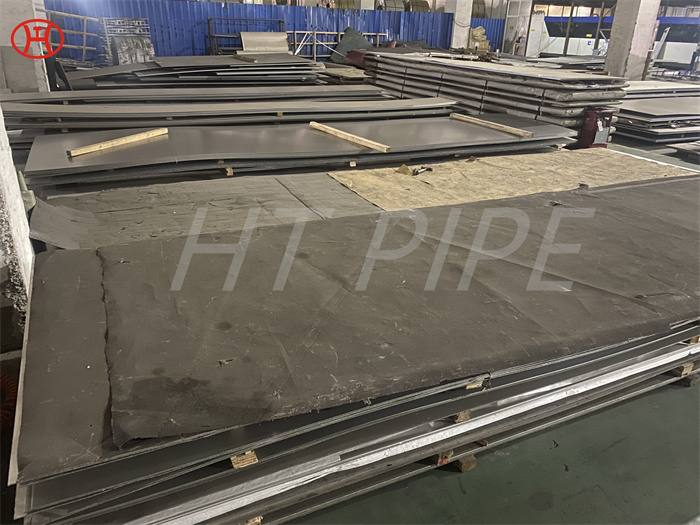

HT PIPE is one of the prime Manufacturer, Exporter and Supplier of Hastelloy C276 Round Bars & Rods that are being sourced by utilizing high caliber of raw material and makes a point to give strength of most elevated nature of industry standard products.

Hastelloy C276, also known as Alloy C276 or UNS N10276 is an austenitic grade alloy. This alloy chemically consists of elements like nickel, molybdenum & chromium as its primary alloying material along with a small addition of tungsten. Hastelloy c276 welding rod is considered to be one of the premier corrosion resistant materials available for process industries in the market.

The molybdenum and high nickel substance in Hastelloy C276 Bars (Alloy C276) make the nickel steel combination especially crevice corrosion and resistant to pitting in plummeting atmospheres, whereas chromium suggests resistance to oxidizing media. Due to its versatility, Hastelloy c276 round bar suppliers recommend this nickel-based C-276 alloy to customers in a variety of industries. This is especially useful in applications where unstable conditions are likely to occur or in multi-purpose plants.

Hastelloy C276, also known as alloy C22, is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. The high chromium content in Hastelloy C276 provides good resistance to oxidizing media while the molybdenum and tungsten content give good resistance to reducing media.

Additionally Known as UNS N10276, these Round Bars and Rods can further be altered as far as sizes and thicknesses according to particular prerequisites given by our regarded customers. Furthermore well known as WNR 2.4819, we offer the same at business sector driving costs.

| Specification | ASTM B574, ASTM B574 UNS N10276 , NACE MR-01-75, ASME SB574 Bar Products, AMS 5750 (Hastelloy C, UNS N10002), Inconel C276 (trademark), Werkstoff Nr. 2.4819, ASTM B751, DIN 17744, DIN 17751, DIN 17750 and DIN 17752,VRC276 |

|---|---|

| Grade | Hastelloy C276 – UNS N10276 |

| UNS N10276 Hex Bar size | 2-100mm A/F |

| ASTM B574 Hastelloy C276 Round bar size | Diameter: 3-~C276mm |

| ASTM B574 Hastelloy C276 Square bar size | 4 to 100mm |

| N10276 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Hastelloy C276 Rectangles Size | 33 x 30mm to 295 x 1066mm |

| ASTM B574 N10276 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| UNS N10276 Section | 3.0 to 12.0mm thickness |

| Hastelloy C276 AMS 5666 Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| N10276 Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| ASTM B574 N10276 Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline, Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Hastelloy C276 Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

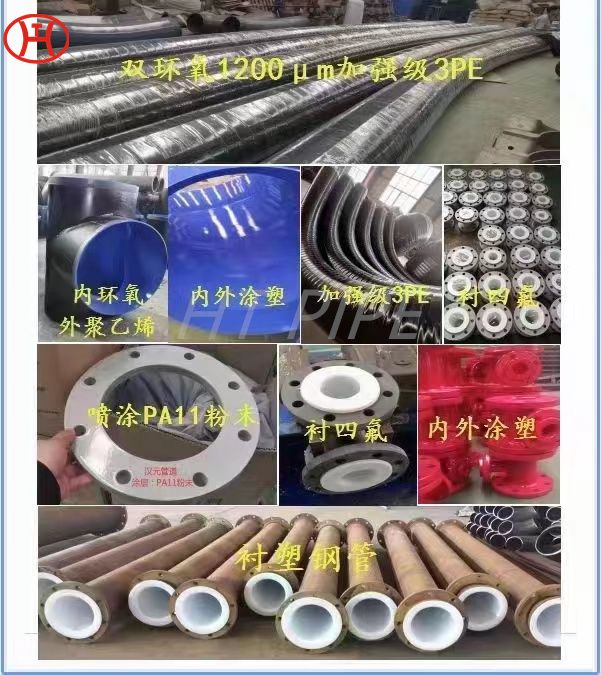

| Form | Hastelloy C276 Round, Welding Rod, T-Bar, Rod, Precision Ground Bar, Channel Bar, Square, Flat Bar, Blocks, Round Rod, Hollow, Rings, Rectangle, Hex (A/F), Triangle, Threaded, Profiles, Billet, Ingot, I/H Bar, Half Round Bar, Forging etc. |

| Our stockyad location for fast delivery across China | Hyderabad, Noida, Shivamogga, Pimpri-Chinchwad, Agra, Coimbatore, Chennai, Tiruchirappalli, Tirunelveli, Bhubaneswar, Mumbai, Pune, Bengaluru, Ahmedabad, Thiruvananthapuram, Dhanbad, Navi Mumbai |

| Our Hastelloy C276 Round bar conforms to NACE MR0175/ISO 15156 | |