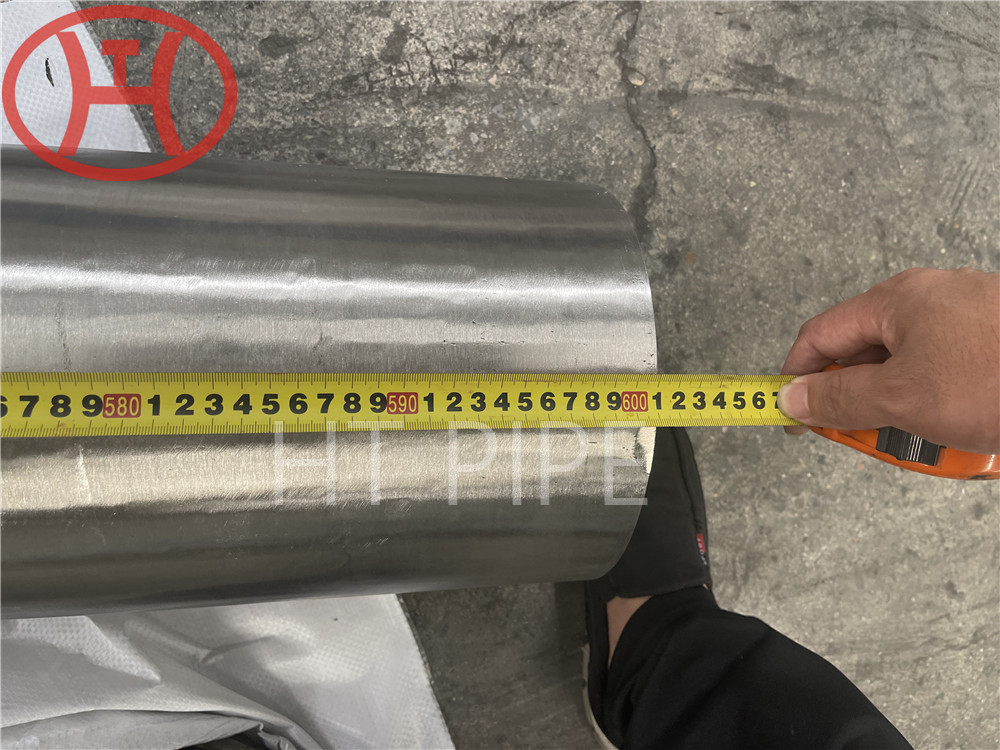

ASTM B164 UNS N04400 monel400 NW 4400 round bar

Monel 400 is resistant to a variety of corrosive conditions. For example, acidic applications involving hydrofluoric acid, brine, sulfuric acid and bases. Alloy 400 can only be hardened by cold work. Monel 400 is used in many industries for its excellent corrosion resistance, especially marine and chemical processing.

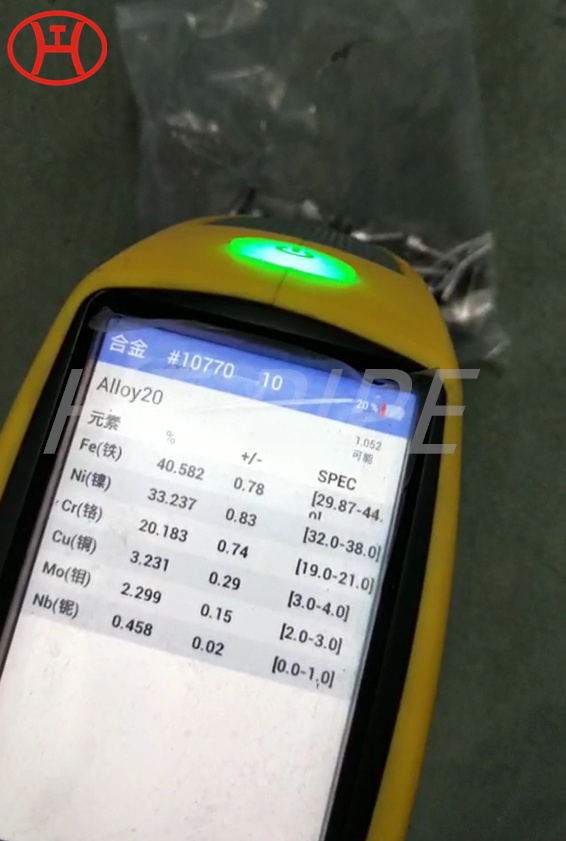

Monel 400 round bars have excellent corrosion resistance to a variety of media. Monel 400 round bars are at least 63% nickel, up to 34% copper, and up to 2% molybdenum. Nickel Alloy 400 Rod, Rod and Wire is a single phase solid solution nickel copper alloy with excellent corrosion resistance to a wide variety of media. Its unique composition combines the precious metal properties of copper with the passivation properties of nickel. The mechanical properties of the 400 at sub-zero temperatures are excellent. The strength and hardness of Alloy 400 increase with a slight decrease in impact resistance or ductility. 400 retains its toughness over a wide temperature range.