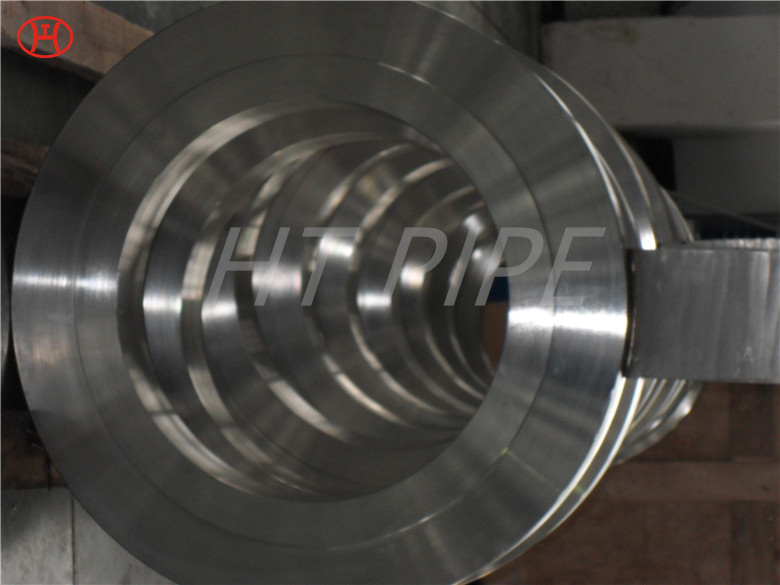

Home » Forged Flanges » ASTM B424 UNS N08825 hot worked spacer ring

ASTM B424 UNS N08825 hot worked spacer ring

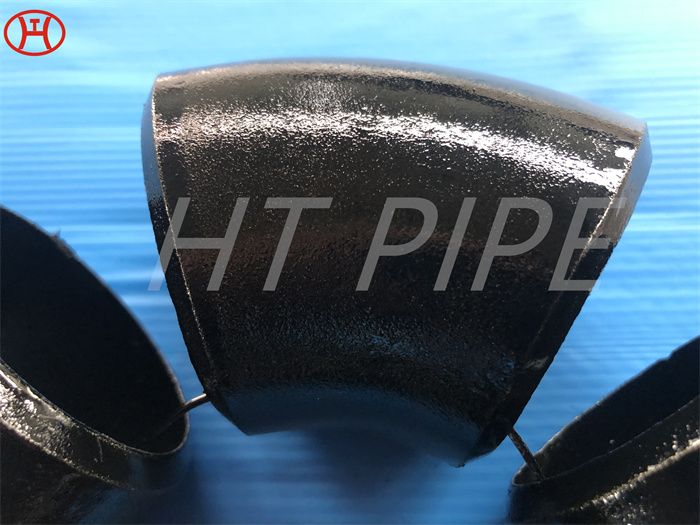

The addition of titanium stabilizes Alloy 825 against sensitization in the as-welded condition making the alloy resistant to intergranular attack after exposure to temperatures in a range that would sensitize un-stabilized stainless steels.

Contact US

Get Price

Share:

Content

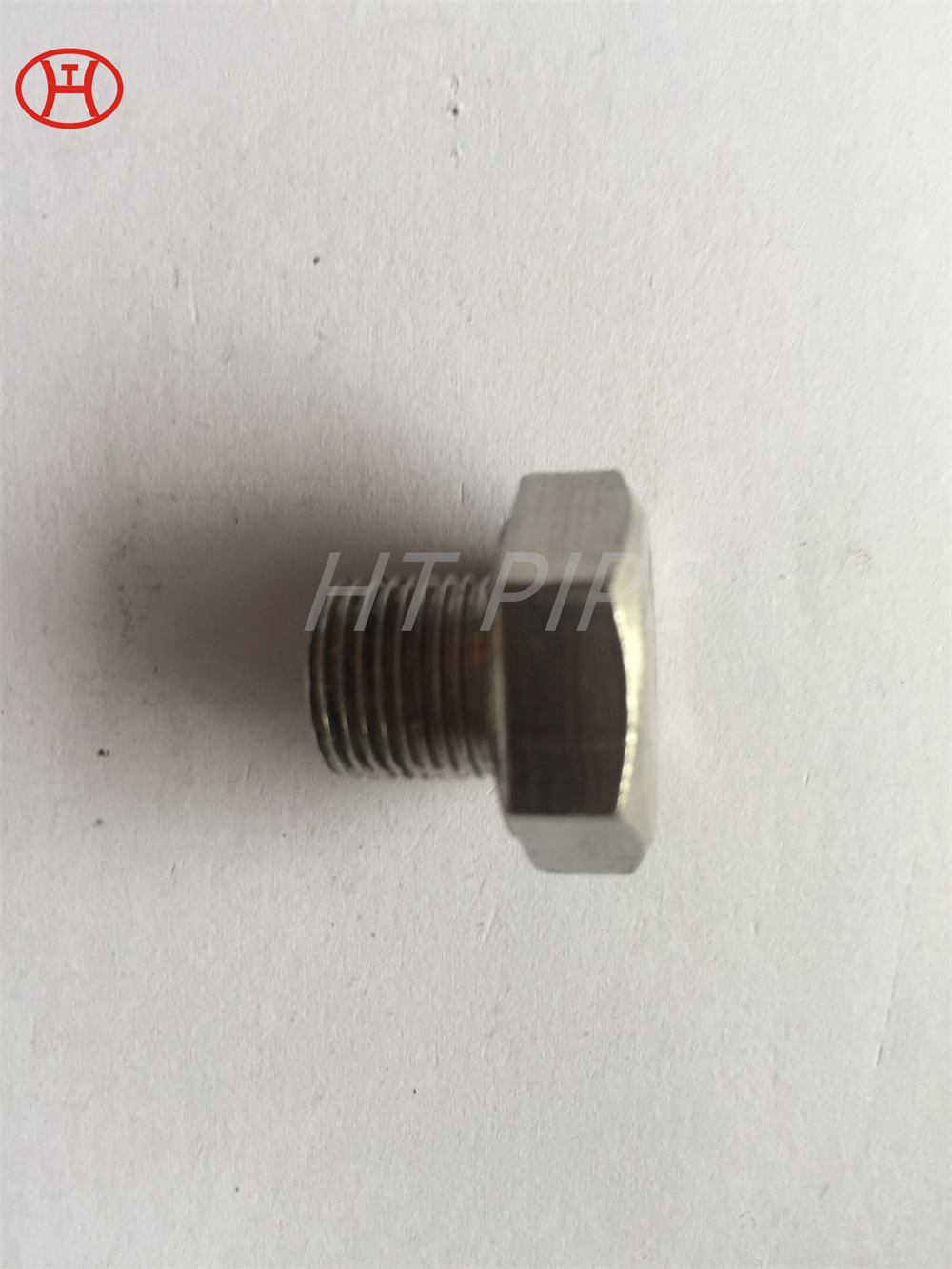

Alloy 825 has good mechanical properties from low to moderately high temperatures. However, exposure to temperatures above 1000¡ãF results in microstructural changes that significantly reduce ductility and impact strength. Alloy 825 should not be used at temperatures where creep rupture characteristics are a design factor. For maximum corrosion resistance, hot worked parts should be stabilized annealed before use. This alloy is easier to cold form than stainless steel.

Inquiry

More Incoloy