ASTM B564 Alloy X Weld Neck Flanges

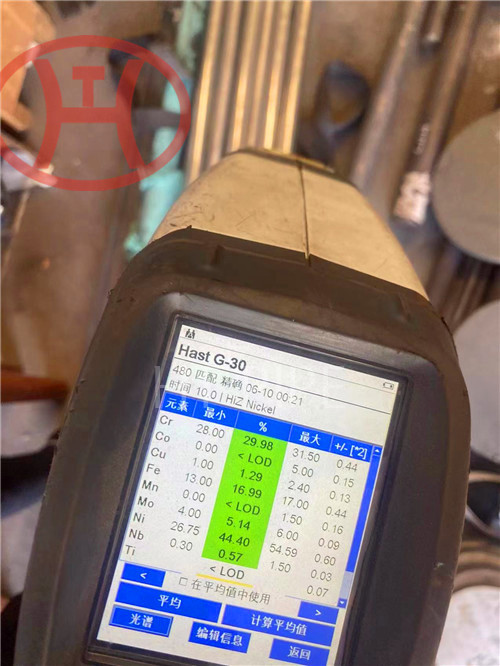

Hastelloy X flanges are high-performance chromium-nickel iron molybdenum super alloy flanges that possess superior corrosion resistance consistency and durability.

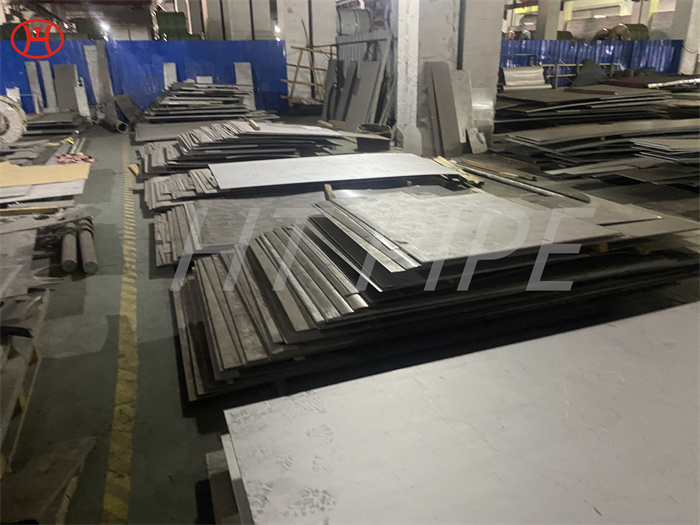

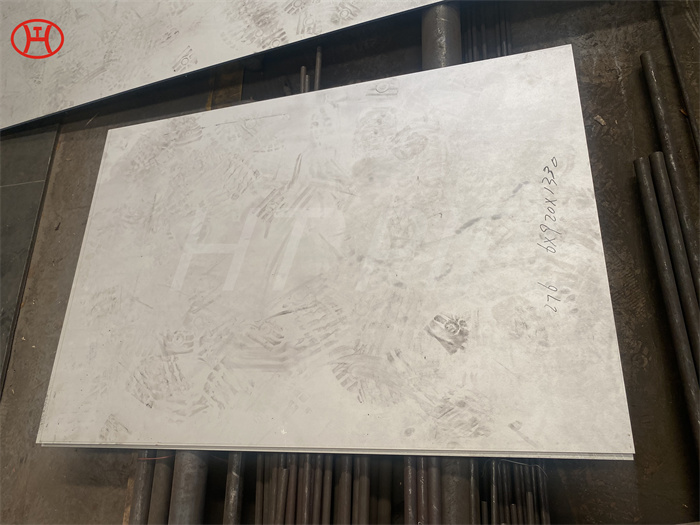

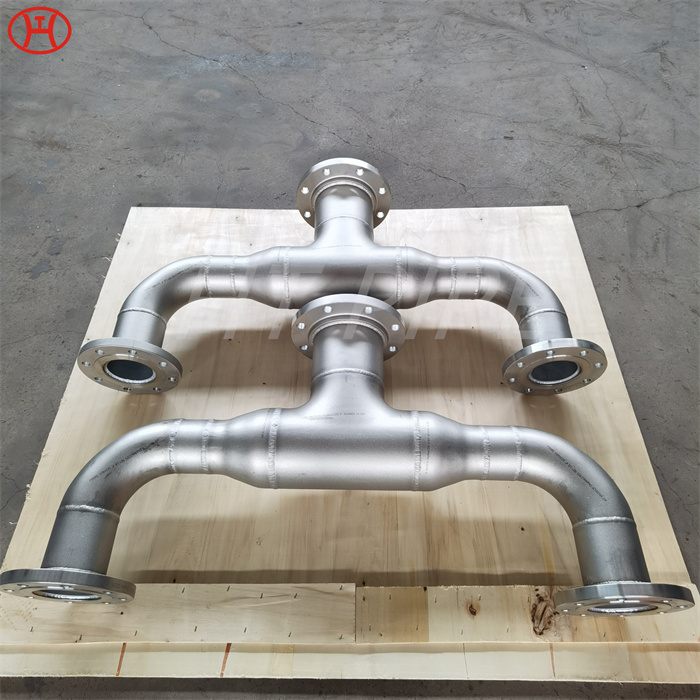

Creative Piping Solutions is one of the most important Manufacturers, Exporter, and Supplier of Hastelloy X Flanges. ASTM B564 Hastelloy X Pipe Flanges is an alloy having excellent resistivity to heat and corrosion. Hastelloy Alloy X Flanges, which is well suited for forming and welding. Hastelloy X Threaded Flanges (UNS N06002) has high strength up to 1500 Degree F (816 Degree C) and good oxidation resistance up to 2200 Degree F (1204 Degree C). Hastelloy X Slip-On Flange one of the world¡¯s hottest proprietary alloys. Hastelloy X Weld Neck Flange has also been found to be exceptionally immune to stress-corrosion cracking in petrochemical applications. Hastelloy X lap joint Flange is one of the foremost widely used nickel-base superalloys for turbine engine components. These alloys of flanges are welded by both automatic and manual methods. Thus these include shielded metal arc, TIG, and MIG methods. Being a certified entity we assure to provide a premium quality product to our customers. However, we use the top-notch quality of raw material for the fabrication process. Hence the production process is under the strict surveillance of our professional experts that have years of experience and knowledge.