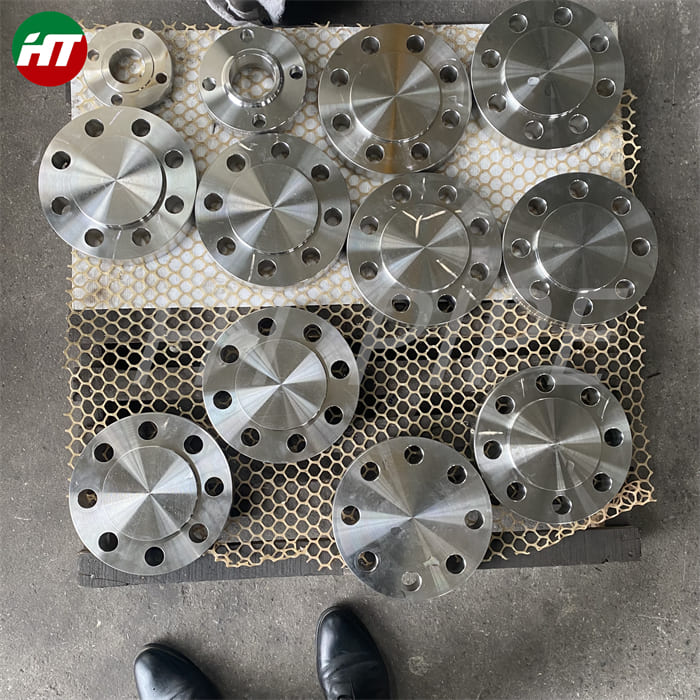

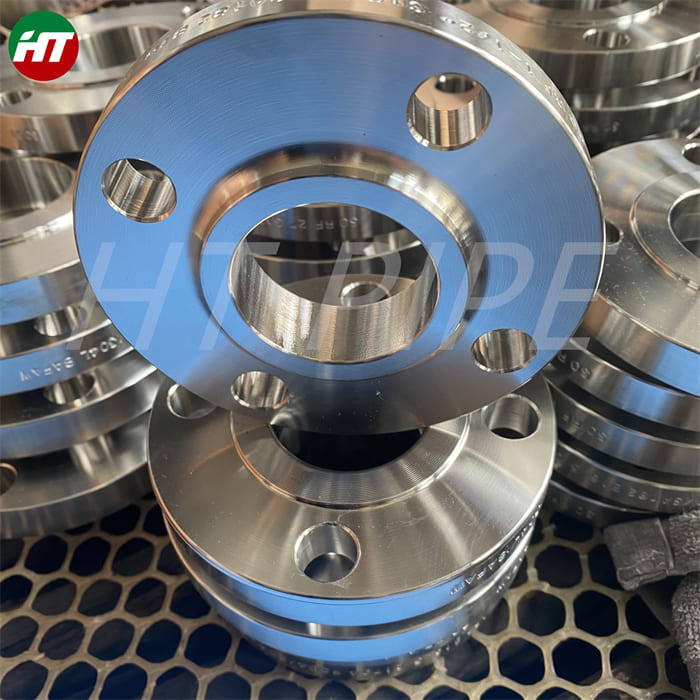

ASTM B564 Inconel Alloy 625 Slip On Flanges Dealer in China

The main applicants of Alloy 625 Forging Flanges include industries like marine and petroleum industries. Other advantages of using the Inconel 625 Flanges involves high fracture toughness as well as fabricability.

This property if the alloy has been derived largely from the solid solution strengthening effects. During the solution strengthening of the Werkstoff No. 2.4816 Alloy 625 Blind Flange the material makes use of refractory metals, such as columbium and molybdenum, which is then stiffened in its nickel-chromium matrix. Nickel based ASTM B564 Inconel 625 Slip on Flanges demonstrates excellent fatigue strength. And like most Inconel alloys, this material too is resistant to stress related corrosion cracking to chloride ions. This rigid material also has a melting point of 1350 degrees Celsius. Depending upon the flange type, the size varies from 12 to 60 inches. Inconel 625 Flanges are extremely resistant to reducing acids, hot saltwater, scrubber environments, and other extremely corrosive conditions. This alloy is notably resistant to pitting and crevice corrosion.