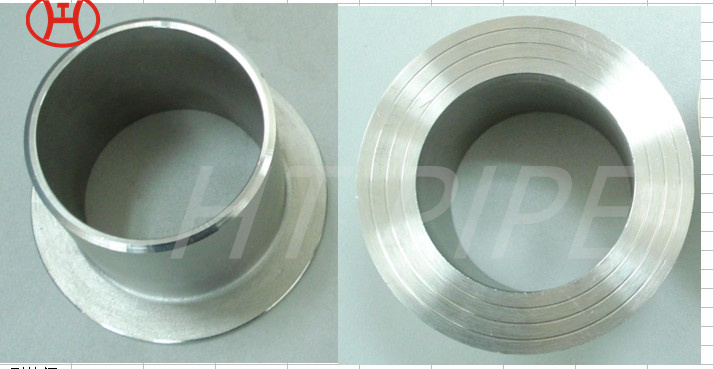

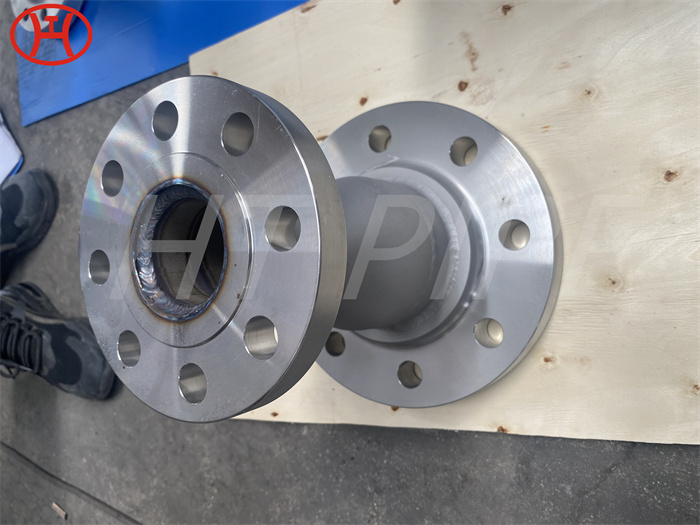

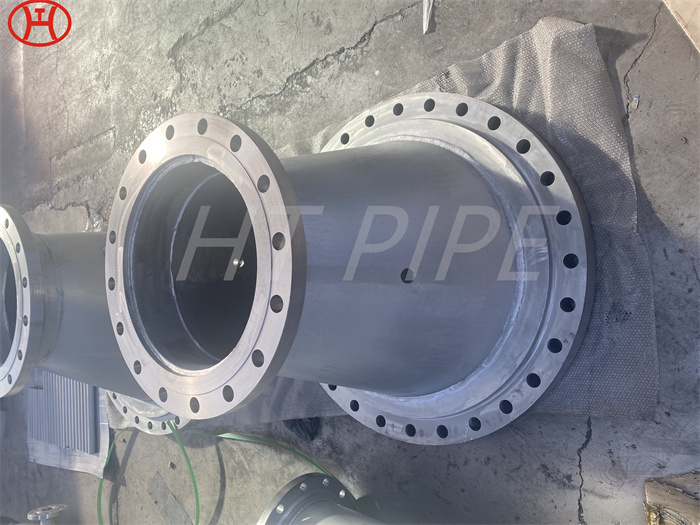

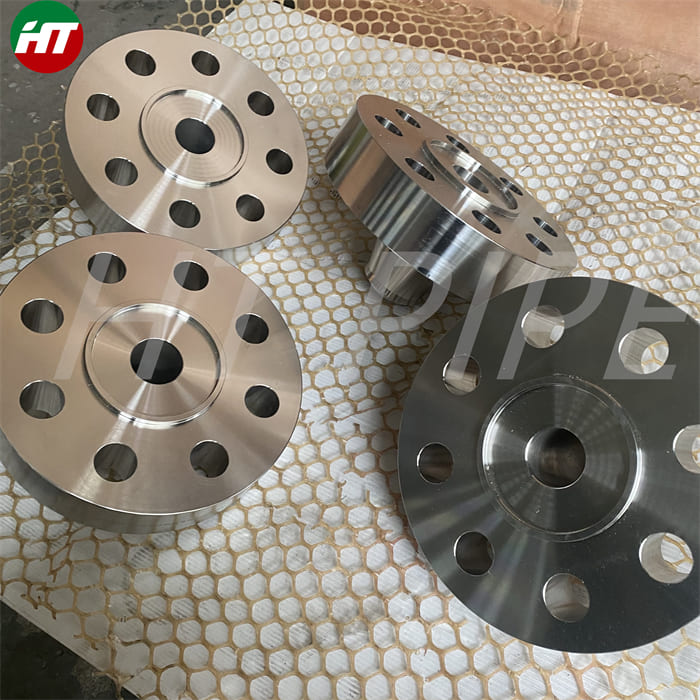

ASTM B564 UNS N06022 N04400 Long Welding Neck Flange

The flange is second most used joining method after selding. Flanges are used when joints need dismantling. It provides flexibility for maintenance. Flange connects the pipe with various equipment and valves. Breakup flanges are added in the pipeline system if regular maintenance in required during plant operation.

A flanged joint is composed of three separate and independent although interrdlated components; the flanges, the gaskets, and the bolting; which are assembled by yet another influence, the fitter. Special controls are required in the selection and application of all there elements to attain a joint, which has acceptable leak tightness.

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength (as the flange of an iron beam such as an I-beam or a T-beam); for easy attachment/transfer of contact force with another object (as the flange on the end of a pipe, steam cylinder, etc., or on the lens mount of a camera); or for stabilizing and guiding the movements of a machine or its parts (as the inside flange of a rail car or tram wheel, which keep the wheels from running off the rails). The term “flange” is also used for a kind of tool used to form flanges.

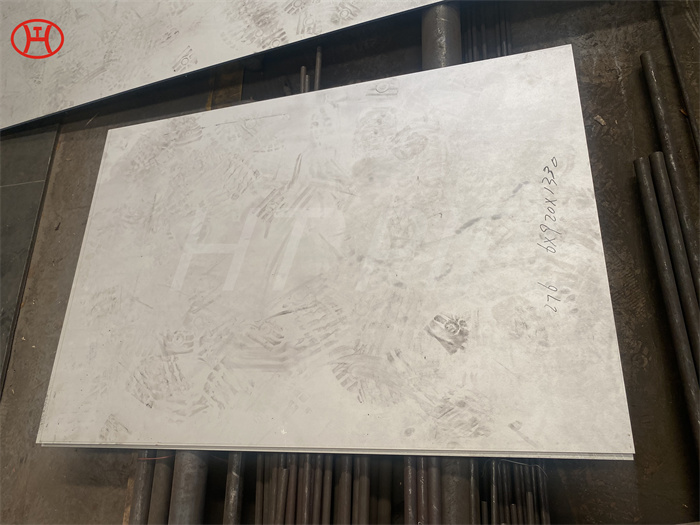

UNS N10665 or W.Nr. 2.4617, Hastelloy B2 (also known as ¡°Alloy B2¡±), is a solid solution strengthened nickel-molybdenum alloy with low addition of carbon, silicon & iron. It has good resistance to hydrogen chloride, sulfuric acid and phosphoric acids and has excellent resistance to stress corrosion cracking and pitting corrosion at elevated temperatures. The significantly low carbon content makes Hastelloy B2 less susceptible to decreased corrosion resistance in the weld zone, in the as-welded condition. It can be used in reducing chemical environments and chemical processing industry. However, Hastelloy B2 should not be used at temperatures between 1000¡ãF and 1600¡ãF nor be used in oxidizing media.

Resists hydrochloric acid at all concentrations and temperatures.

Withstands wet HCl gas, sulfuric, acetic and phosphoric acids.

Excellent resistance to pitting and to stress corrosion cracking.

Acetic acid production, initial phase in presence of iodide catalyst.

Methyl methacrylate production with hot 98% H2SO4.

Production of herbicides, insecticides, ethylene glycol and ethyl benzene.

Butane isomerization to produce high octane gasoline.

Resists corrosion from antimony chloride.