ASTM B574 UNS N10276 Nickel Alloy Bar Hastelloy C276 Wire

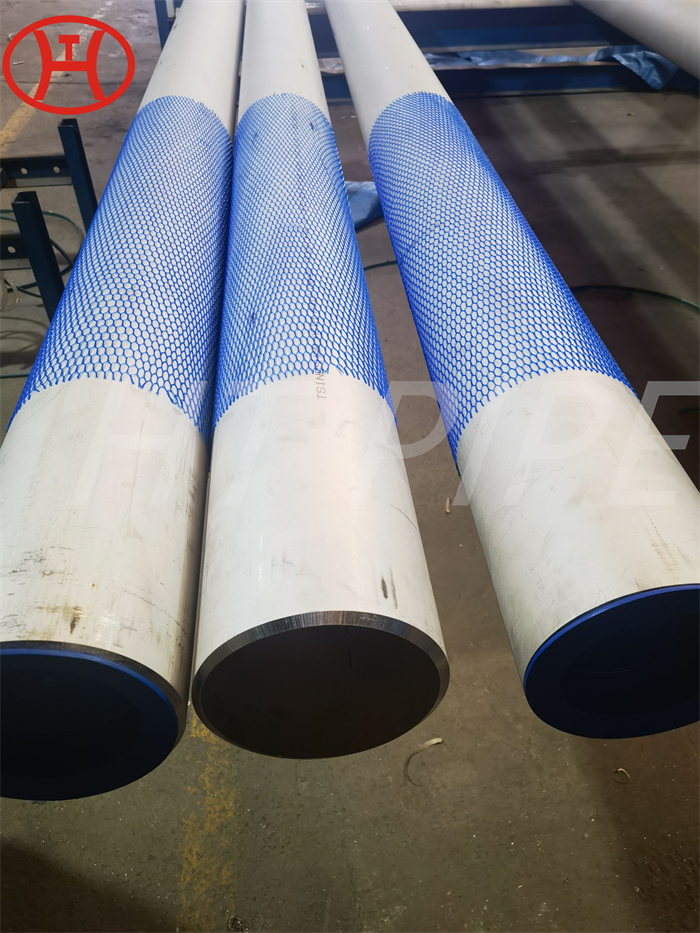

The ASTM B574 Standard specifies the requirements for nickel alloy bars made from UNS N10276, N06022, N06035, N06455, N06058, and N06059 alloys. These ASTM B574 Alloys exhibit excellent corrosion resistance properties and are widely used in the chemical processing, oil and gas, and power generation industries.

Hastelloy c276 Wire, Hastelloy C276 Bar ASTM B574 N10276 Bars, ASTM B574 UNS N10276 Round Bar, ASTM B574 UNS N06022 Nickel Alloy Bars, ASTM B574 UNS N06035 Nickel Alloy Bars, ASTM B574 UNS N06455 Nickel Alloy UNS N06058 Bars.

The ASTM B574 Standard specifies the requirements for nickel alloy bars made from UNS N10276, N06022, N06035, N06455, N06058, and N06059 alloys. These ASTM B574 Alloys exhibit excellent corrosion resistance properties and are widely used in the chemical processing, oil and gas, and power generation industries.

UNS N10276, also known as Hastelloy C-276, is a popular nickel alloy that offers superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Hastelloy c276 Wire is commonly used for applications involving sulfuric acid, hydrochloric acid, and chlorine gas.

N06022 is another nickel alloy that offers excellent resistance to both oxidizing and reducing environments, including wet chlorine gas, acetic acid, and sulfuric acid. Its high chromium, molybdenum, and tungsten content make ASTM B574 UNS N06022 Nickel Alloy Bar an ideal choice for use in aggressive chemical environments.

N06059 is a nickel alloy bar that exhibits high resistance to stress corrosion cracking and pitting in chloride-containing environments. ASTM B574 UNS N06035 Nickel Alloy Bar is commonly used in the chemical, petrochemical, and oil and gas industries, where it is exposed to harsh conditions such as hot sulfuric acid and seawater.

The ASTM B574 standard sets strict guidelines for the chemical composition, mechanical properties, and testing requirements for Hastelloy c276 Wires. These guidelines ensure consistent quality and performance of the alloys.

Nickel alloy bars made from UNS N10276, N06022, and N06059 alloys play a vital role in various industrial applications due to their excellent resistance to corrosion and other harsh environments. The ASTM B574 standard provides a framework for ensuring that these ASTM B574 UNS N10276 Round Bars meet the necessary requirements for quality and performance.

ASTM B574 Bar Specification

| Specification | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Standard | ASTM B574 / ASME SB574 |

| Size | 5 mm To 500 mm |

| Diameter | 0.1 mm to 100 mm |

| Length | 100 mm To 3000 mm Long & Above |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

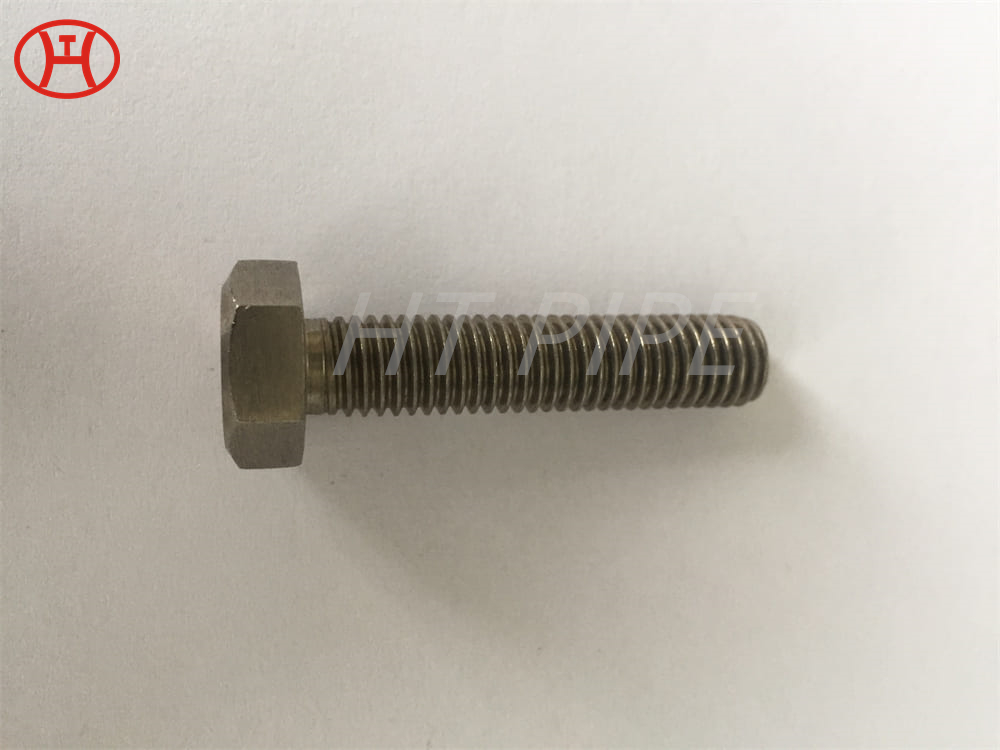

| Form | Round Bars, Square Bars, Flat Bars, Threaded Bars, Hollow Bars, Hexagonal Bars, Triangular Bars |

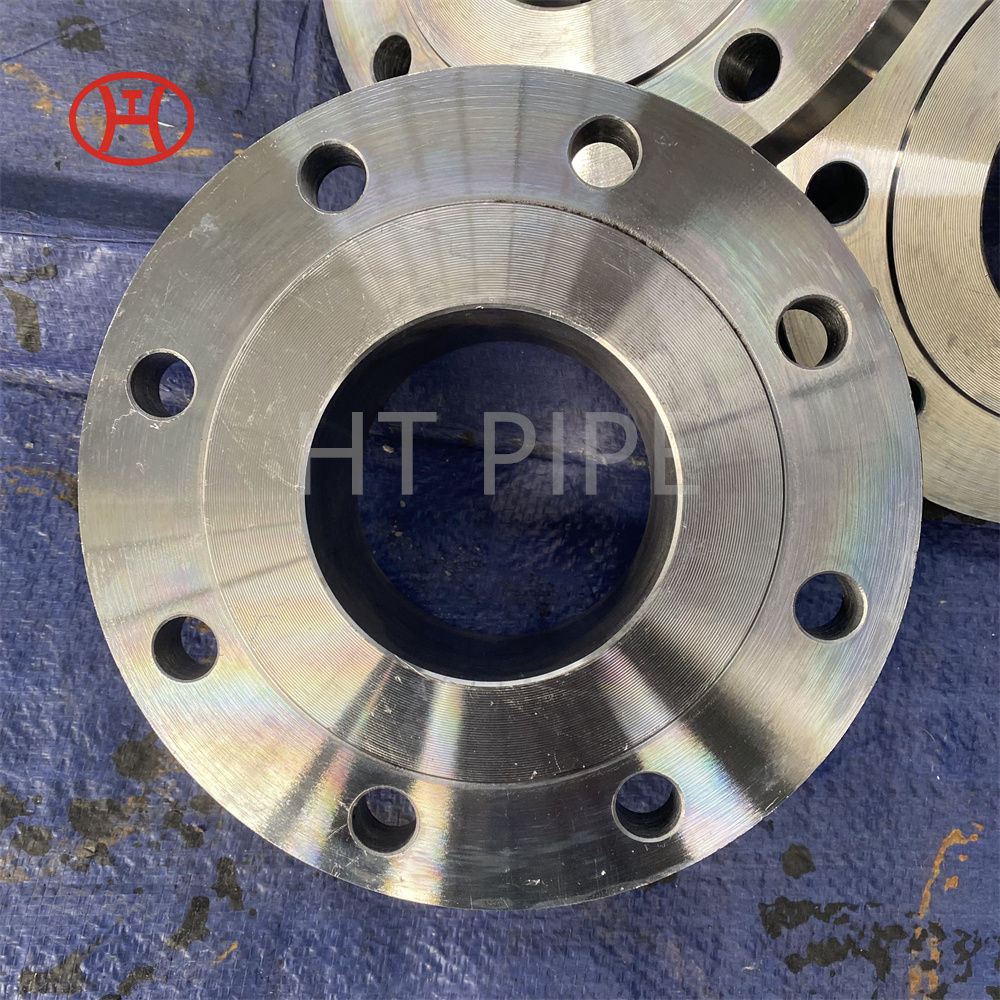

| Application | Most commonly used in petroleum refineries, Boilers, Heat exchangers, Condensers, Pipelines, Cooling towers, Steam exhausts, Electric generation plants, fertilizer and chemical plants. |