best nickel alloy incoloy seamless pipe tube price 800

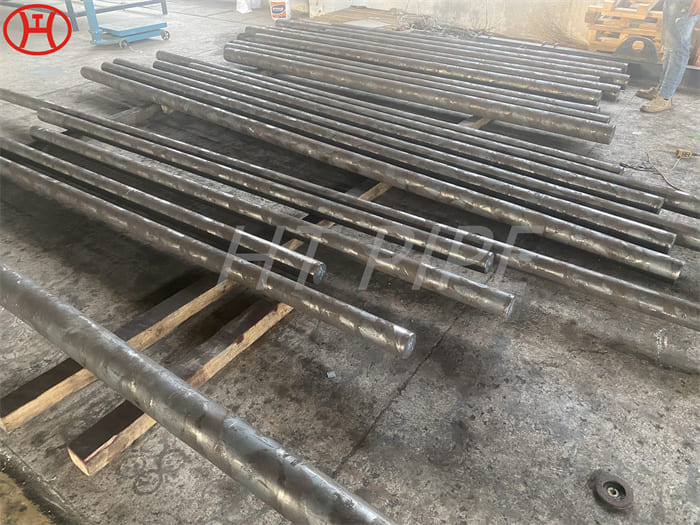

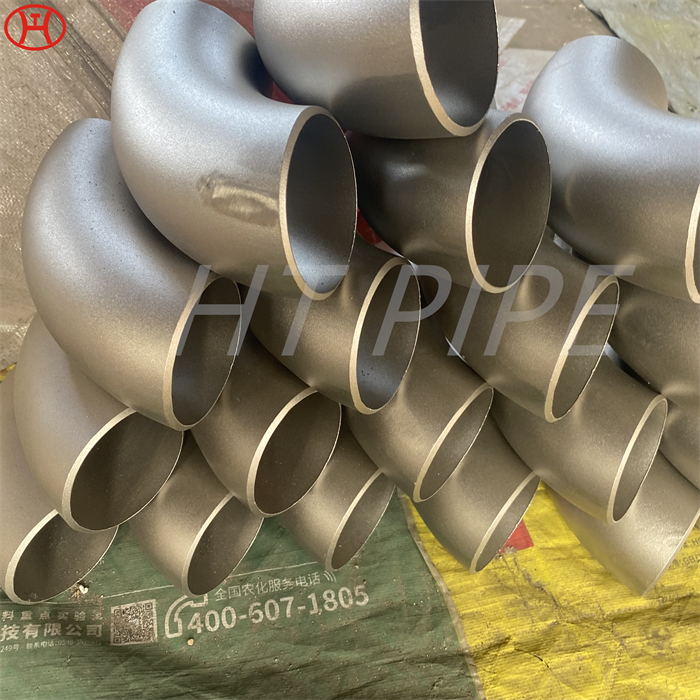

High performance nickel alloys for sour oil and gas fields. ASTM B407/B358 Incoloy 800 pipe-hardened nickel-based alloys and cold-worked solid nickel-based alloys offer many advantages, such as high strength, toughness, low magnetic permeability, and excellent corrosion resistance. ASTM B407/B358 Incoloy 800 pipe has proven to be a valuable and versatile material that can solve a variety of design and application problems. ASTM B407/B358 Incoloy 800 pipe resists low temperature aggressive corrosive environments as well as harsh high temperature environments. This alloy has excellent weldability and is able to join very successfully with other alloys with different compositions.

Incoloy 800 seamless pipe and Inconel 800h pipe have good strength and excellent resistance to oxidation and carburization in high temperature environments. Alloy 800 Seamless Tubing and Alloy 800 Gas Tubing are also resistant to corrosion in many aqueous environments. Inconel and Incoloy belong to the same family of superalloys, but each has its own unique characteristics and other things in common. Also known as high-performance alloys, superalloys typically offer high resistance to corrosion and oxidation, as well as mechanical strength at elevated temperatures. The most fundamental difference between them is their composition. Inconel, primarily a nickel-chromium alloy, typically contains more than 50% nickel, while Incoloy, a nickel-iron-chromium alloy, contains less than 50% nickel.