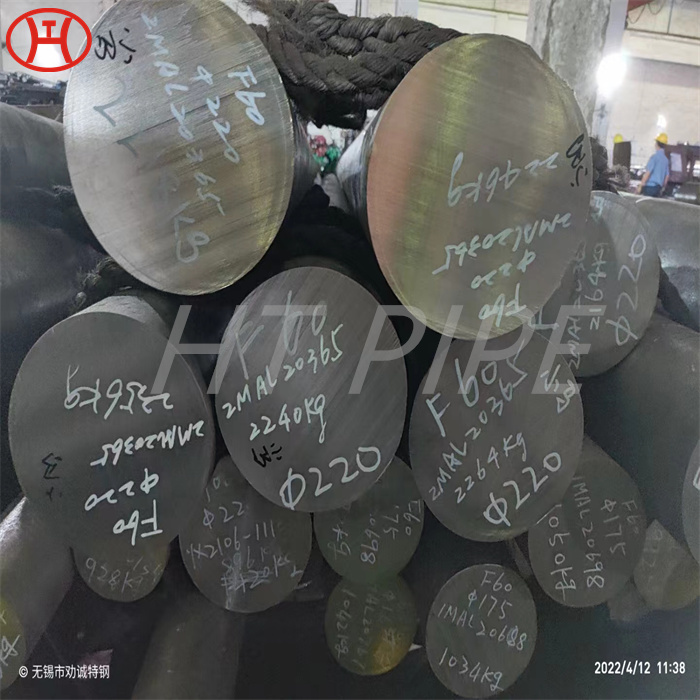

bright round bar Inconel 718 nickel alloy steel round bar 2.4668 forged round bar

Inconel 718 is a precipitation hardening nickel-chromium based superalloy. ASTM B637 UNS N07718 round bars also contain significant amounts of elements such as iron, niobium and molybdenum, and trace amounts of metals such as aluminum and titanium. Aluminum and titanium make Inconel 718 hardenable.

Alloy 718 is classified as “age hardenable”, which means its resistance properties increase over time – especially with prolonged exposure to low temperatures. Many AMS and NACE specification processes can be deployed to customize their application-specific performance characteristics. AMS 5662 Inconel 718 Black Bar is ideal for applications requiring high tensile strength in the high temperature range from low temperature to about 1400°F. In addition to having excellent tensile properties, ASTM B637 bar also has good impact strength. Also, like most nickel alloys, the chemistry of ASTM B637 UNS N07718 is designed for use at elevated temperatures. Inconel 718 bars are precipitation hardened to optimize the alloy’s tensile strength properties. Age hardening of Inconel 718 Square Bar is a great way to improve the tensile properties of a product by adding some trace elements to the alloy before heating. In this process, nickel combines with niobium to form a gamma binary phase.

The exhibition photos of Inconel 718 bar