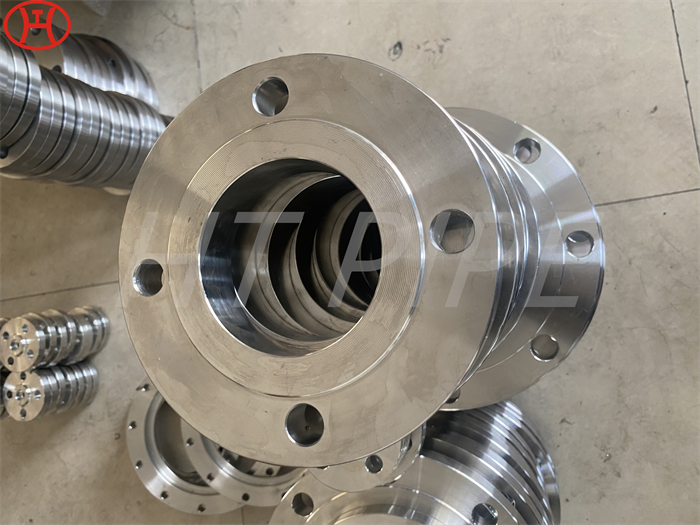

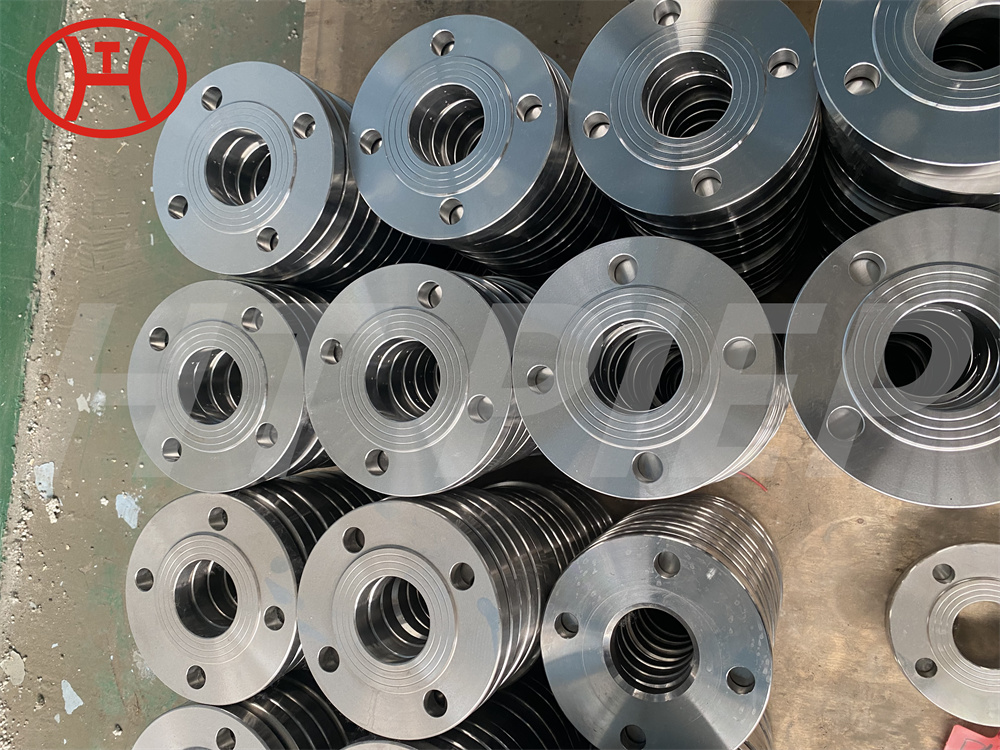

Butt-welding Pipe Fittings 304 1.4301 Stub End

Grade 304 stainless steel is generally considered the most common austenitic stainless steel. It contains a high nickel content, typically between 8 and 10.5 weight percent, and a substantial amount of chromium around 18 to 20 weight percent. Other major alloying elements include manganese, silicon and carbon. The rest of the chemical composition is mainly iron.

Stainless steel is less prone to staining than other iron-based metals, but it’s not literally “stainless steel.” Just like standard steel, stainless steel can be marked, discolored, and eventually rusted by fingerprints and grease. The difference is toughness. Stainless steel can withstand more time and abuse before showing signs of wear.

Grade 304L is a low carbon version of 304 that does not require post weld annealing and is therefore widely used for large gauge components (approximately 6mm+). The higher carbon grade 304H is used for high temperature applications. The austenitic structure also gives these grades excellent toughness, even at low temperatures.

It’s just a molecular structure made of an iron-chromium-nickel alloy mixture. It makes 304 steel essentially non-magnetic, and since austenitic steels are generally low carbon, it is less vulnerable to intergranular corrosion. 304 steel welds well with most welding methods and can be easily drawn, formed and rotationally formed with or without filler.