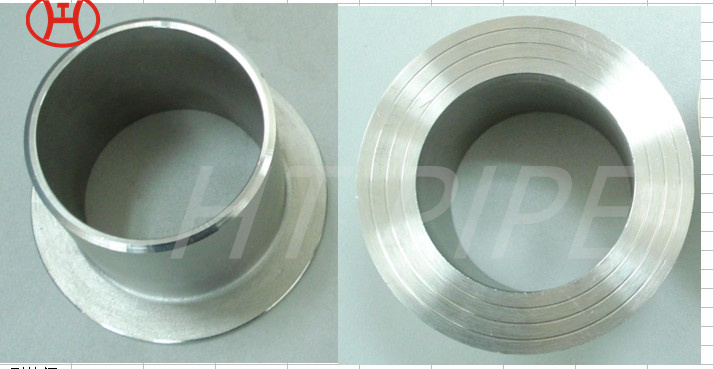

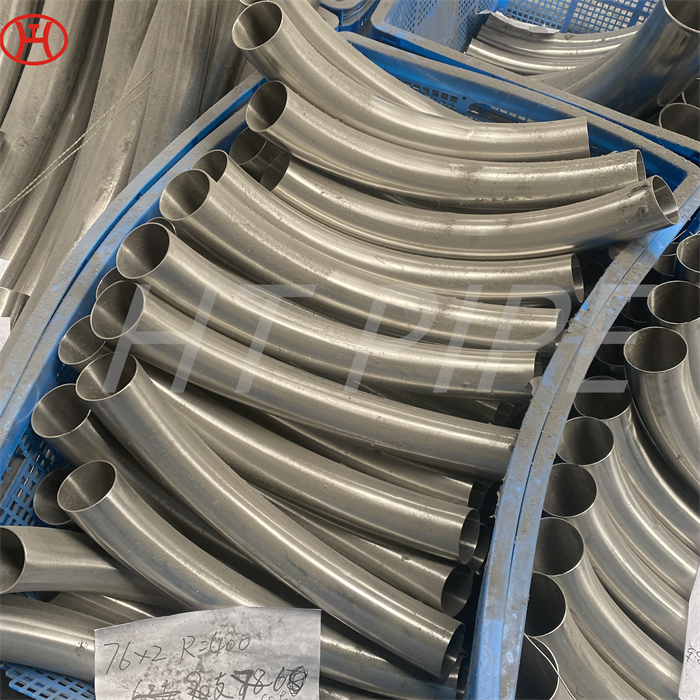

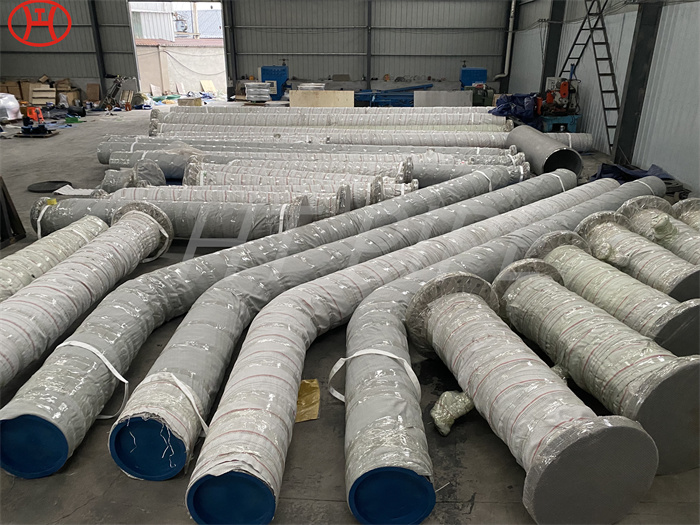

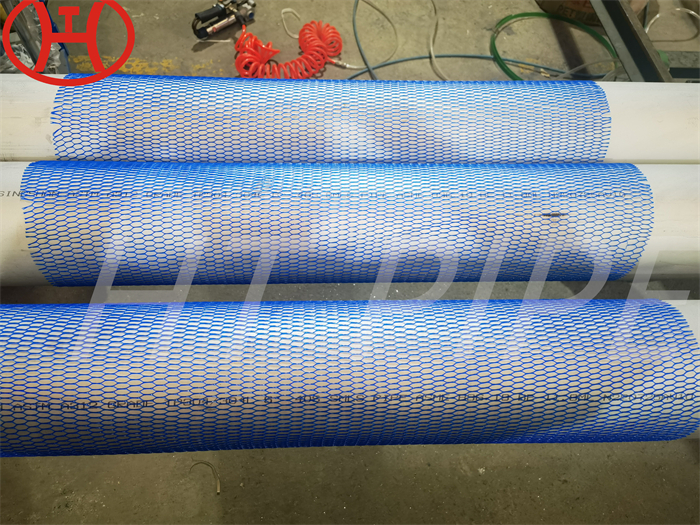

Butt-welding Pipe Fittings Hastelloy B3 N10675 Stub End

Hastelloy B-3 is a nickel-molybdenum alloy with excellent resistance to pitting, corrosion and stress corrosion cracking and better thermal stability than alloy B-2. In addition, this nickel-steel alloy is highly resistant to knife-line and heat-affected zone attacks.

Alloy B-3 is also resistant to sulfuric, acetic, formic and phosphoric acids and other non-oxidizing media. In addition, this nickel alloy has excellent resistance to hydrochloric acid at all concentrations and temperatures.

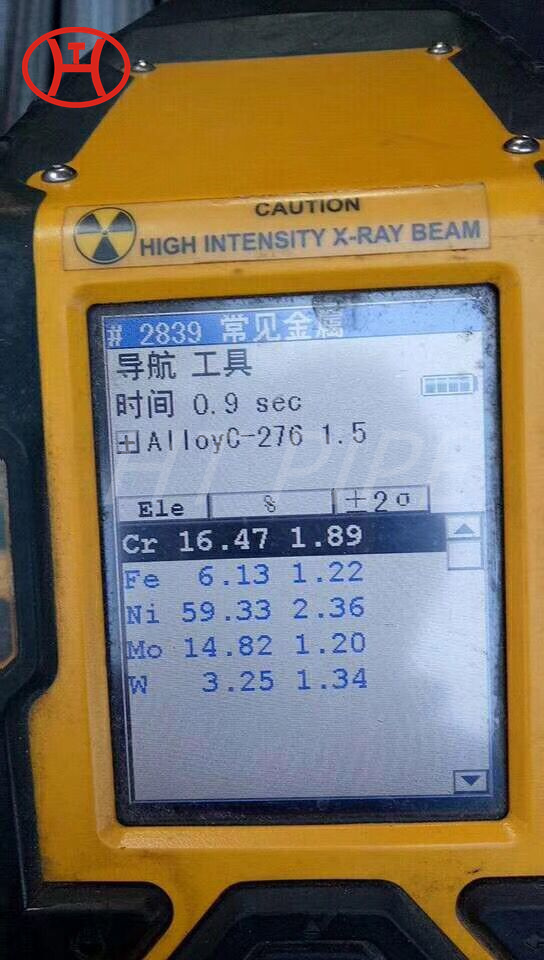

UNS N10675 or W.Nr. 2.4600, Hastelloy B3 (also known as “Alloy B3”), is a nickel-molybdenum alloy to which elements such as chromium and iron have been added. It has excellent resistance to hydrochloric acid at all concentrations and temperatures. It also has good performance in non-oxidizing media such as sulfuric acid, acetic acid, formic acid and phosphoric acid.

Hastelloy B-3 is a nickel-molybdenum alloy with excellent resistance to pitting, corrosion and stress corrosion cracking, and has better thermal stability than alloy B-2. This alloy also has good resistance to knife line and heat-affected zone attacks. The improved thermal stability of B-3 alloy minimizes the problems associated with the manufacture of B-2 alloy parts.