C2000 Hastelloy Alloy Tubing Hastelloy C2000 Seamless Pipe

Hastelloy C2000 Tubes are used in a broad range of industries including petrochemical processing, chemical processing equipment manufacturing, oil refineries and power plants.

C2000 Hastelloy Alloy Tubing, Hastelloy C2000 Seamless Pipe, Hastelloy C2000 Tube, Hastelloy C-2000 Pipes Exporter, Hastelloy Alloy C2000 ERW Tube Suppliers, ASTM B622 Hastelloy Alloy C2000 Seamless Pipes, ASTM B619 Hastelloy Alloy C2000 Welded Round Pipes Stockholders.

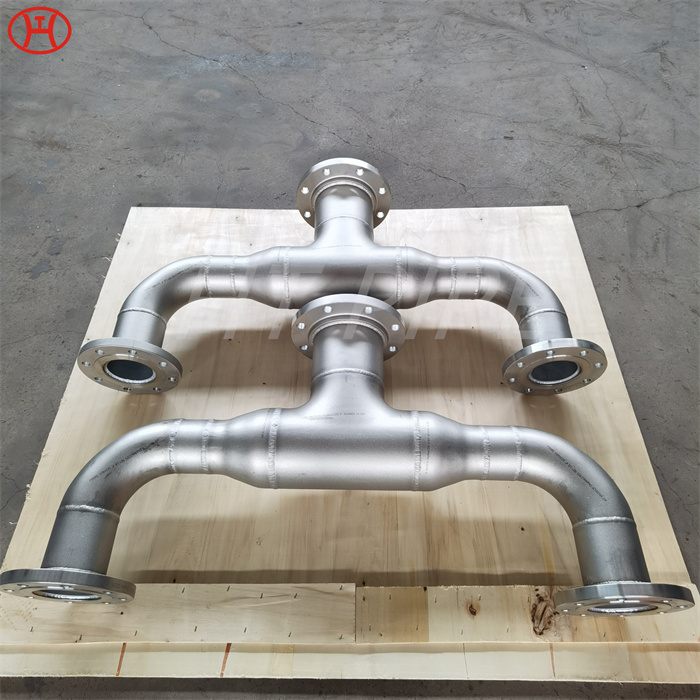

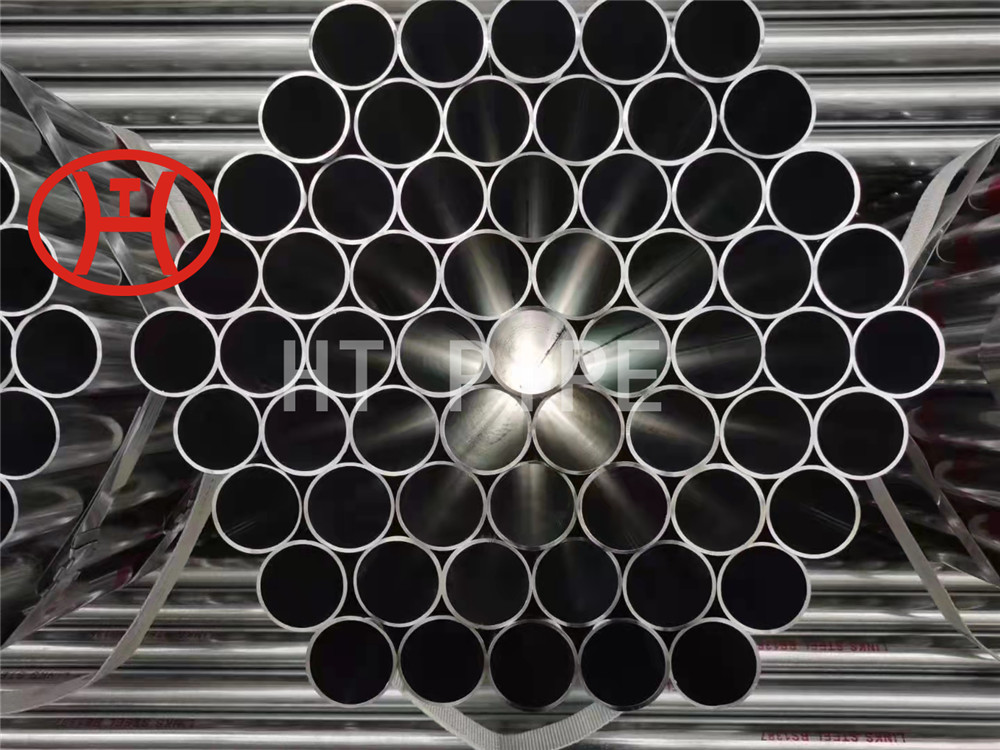

Hastelloy C2000 Tubes are used in a broad range of industries including petrochemical processing, chemical processing equipment manufacturing, oil refineries and power plants. C2000 Hastelloy Alloy Tubing is perfect for applications that require resistance to general corrosion, stress corrosion cracking (SCC), pitting and crevice corrosion as well as oxidation resistance up to 2000°F (1093°C). Hastelloy C2000 ERW Tubes are commonly used in heat exchangers, condensers and evaporators because Hastelloy C2000 Seamless Pipe performs better than many other alloys when exposed to seawater or water containing chlorine ions. Hastelloy B3 Pipes, Hastelloy C22 Tubes and many more grades are also available.

HASTELLOY C-2000 alloy (UNS N06200) is unique among the versatile nickel-chromium-molybdenum materials in having a deliberate copper addition. Hastelloy C-2000 Pipe provides greatly enhanced resistance to sulfuric acid. Hastelloy Alloy C2000 ERW Tube also has a high chromium content, to maximize its resistance to oxidizing chemicals and process streams contaminated with ferric ions and dissolved oxygen. Like other nickel alloys, ASTM B622 Hastelloy Alloy C2000 Seamless Pipe is ductile, easy to form and weld, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to which the austenitic stainless steels are prone). ASTM B619 Hastelloy Alloy C2000 Welded Round Pipe is able to withstand a wide range of oxidizing and non-oxidizing chemicals, and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides.

ALLOY C-2000 PIPE SPECIFICATION

| Standards | ASTM B619, ASTM B622 / ASME SB619, ASME SB622, ASTM B 619; ASME SB 619 (Welded); ASTM B 622; ASME SB 622 (Seamless); ASTM B626; ASME SB626 (Welded Tube). |

| Hastelloy C2000 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Hastelloy C2000 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Hastelloy C2000 tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Alloy C2000 tube Length | Single Random, Double Random, Standard & Cut length |

| Hastelloy Alloy C2000 Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

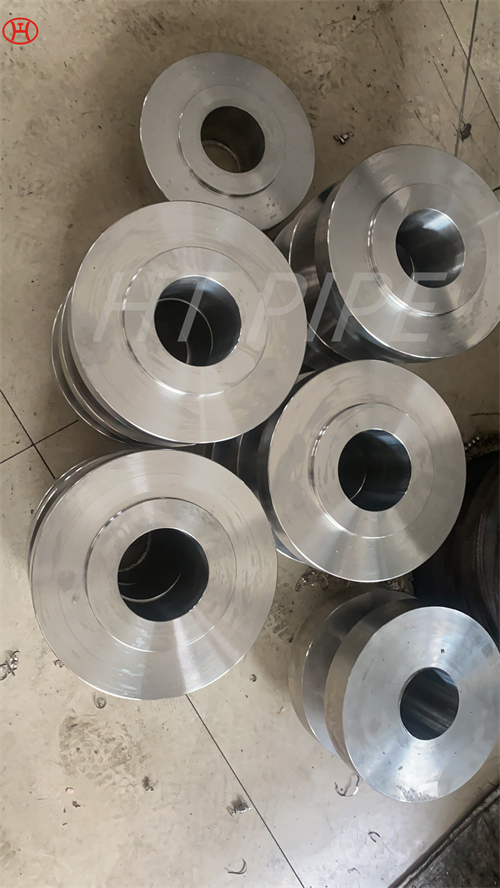

| Hastelloy C2000 tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Hastelloy C2000 Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| End | Plain End, Beveled End, Treaded |

| Marking | All Hastelloy Alloy C2000 tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | Hastelloy C2000 Capillary Tube & Other Odd Size Hastelloy C2000 Heat Exchanger & Condenser Tubes |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Manufacturers of Hastelloy C2000 Tubes & Tubing | Sumitomo Metals, Japan

Nippon Steel Corporation, Japan Kobe Special Tube, Japan Sanyo Special Steel, Japan Tubacex Tubos Inoxidables S.A., Spain Schoeller Bleckmann, Austria Seah Steel Corporation, Korea |

| We can also cut, thread, and groove Hastelloy C2000 Tubes to meet your specifications | |